Best Sellers

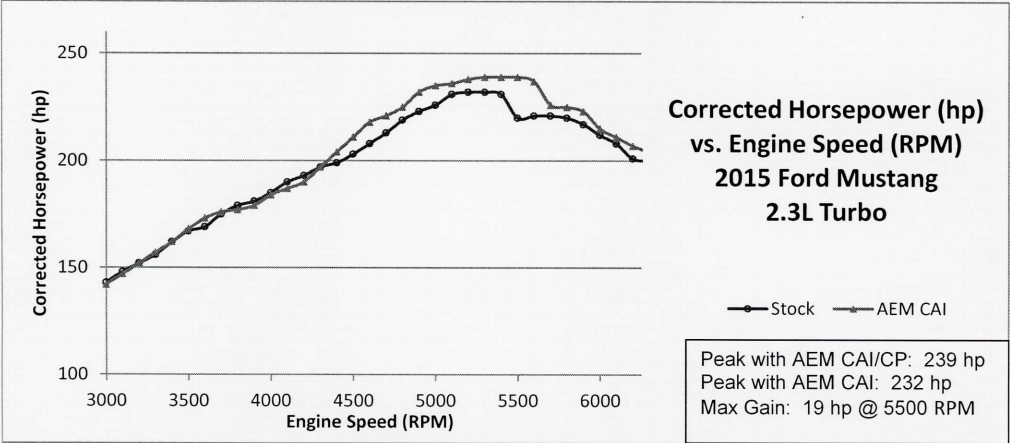

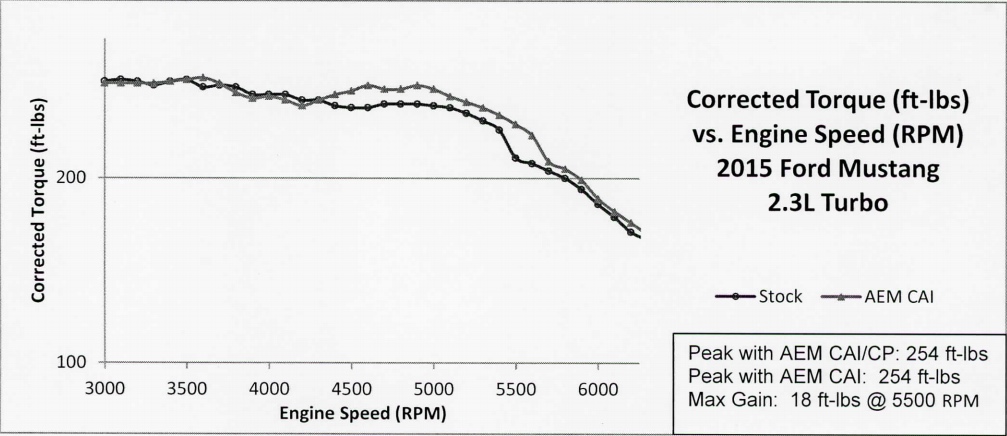

How to Install AEM Intercooler Charge Pipe Kit on your Mustang

Installation Time

2 hours

Tools Required

- Screw Driver

- 10mm Socket

- 8mm Socket

- 7mm Socket

- Socket Driver

- Pliers

- Universal Joints

- Driver Extensions

Shop Parts in this Guide

1. Preparing Vehicle

a. Make sure vehicle is parked on level surface

b. Set the parking brake

c. If engine has run in the past two hours, let it cool down.

d. Disconnect negative battery terminal.

e. Do not discard stock components after removal of the factory system

f. Open the air intake kit package and make sure all parts are included.

2. Removal of stock system

a. use 10mm socket to remove the bolt securing the factory air box.

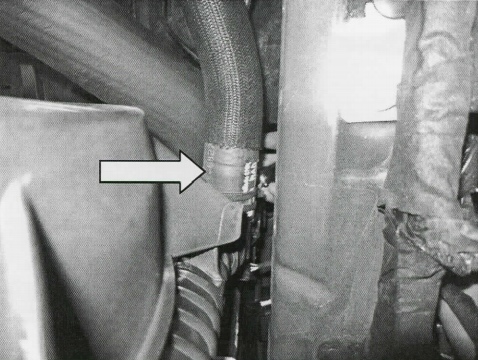

b. Remove wiring harness from the inlet air temperature (IAT) sensor and use pliers to remove the harness from the air box where shown by the arrow above.

c. Use pliers to release the clamp securing the recirculation hose to the factory intake tube and disconnect the hose from intake tube.

d. Remove and disconnect the PCV hose from the intake tube.

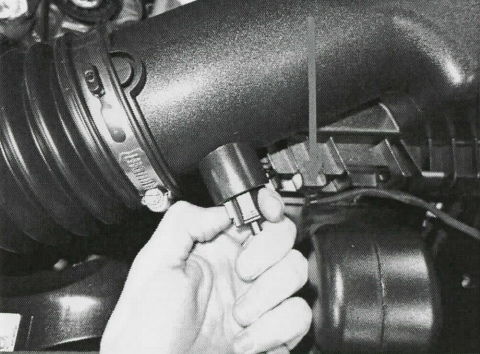

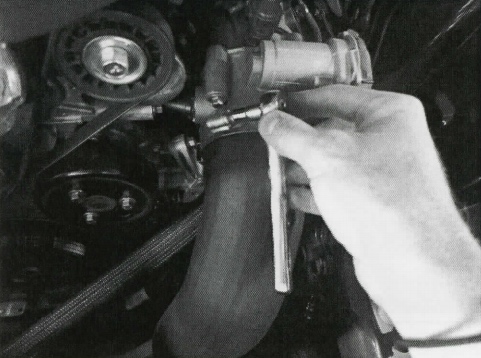

e. Use a 7mm socket to loosen the hose clamp securing the coupler to the turbo compressor inlet and remove the coupler from the turbo.

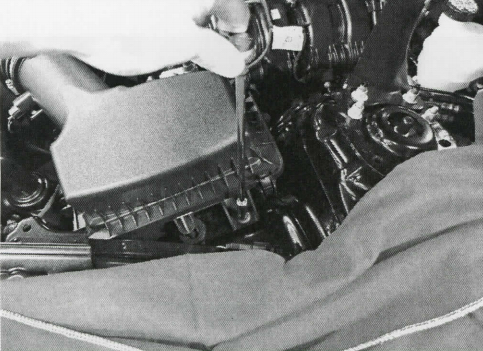

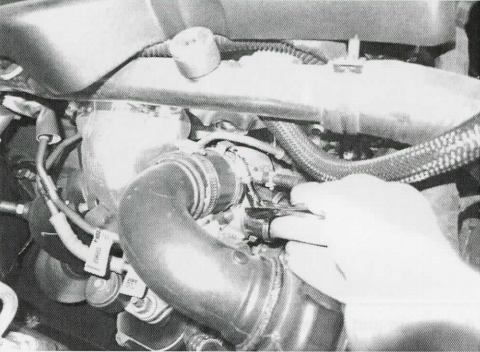

f. Remove the factory intake assembly by lifting out as shown.

g. With the factory intake system removed, begin removing the factory charge plumbing by loosening the clamp securing the cold-side charge hose to the throttle body using a 7mm socket.

h. Loosen the clamp holding the other end of the hose to the intercooler. This may require reaching around the frame rail to access the clamp with the 7mm socket. Once loose, remove the factory cold-side charge hose.

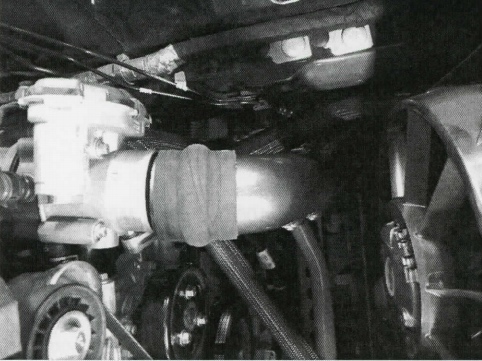

i. Loosen the clamp securing the hot-side charge pipe coupler to the turbo outlet with a 7mm socket.

j. Disconnect the wiring harness connected to the recirculation valve.

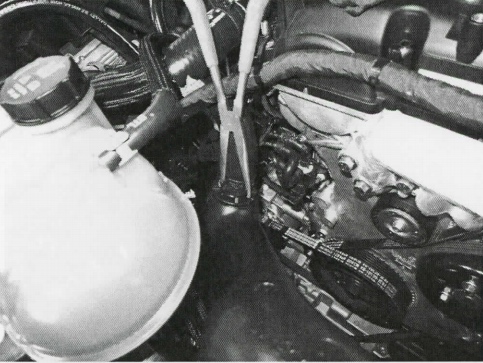

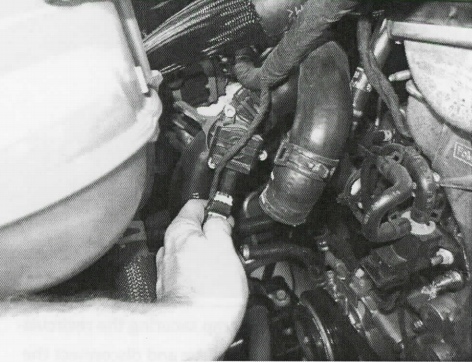

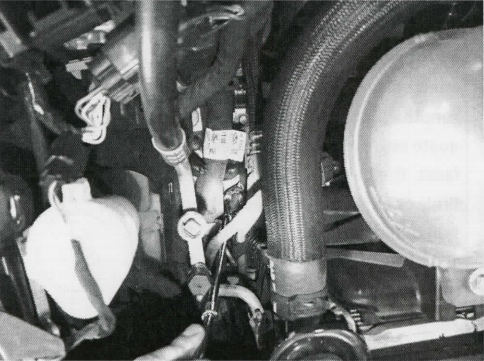

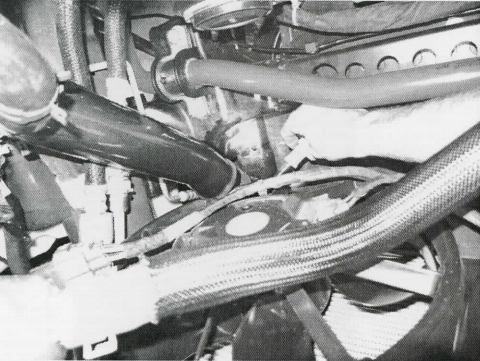

k. Loosen the hose clamp securing the hot-side charge tube to the intercooler using a 7mm socket at the end of a universal joint on extensions as shown above.

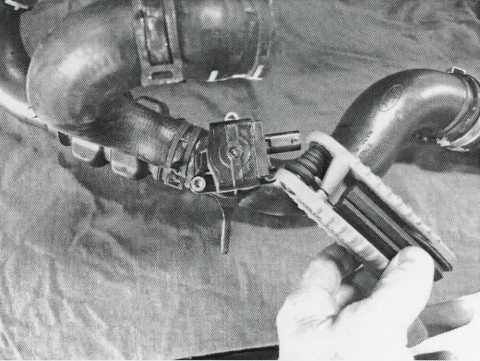

I. Pull the factory hot-side charge tube out and remove the recirculation valve. This valve will be reinstalled on your new AEM charge pipe.

3. Installation of AEM@ intake system.

a. When installing the intake system, do not completely tighten the hose clamps or mounting hardware until instructed to do so.

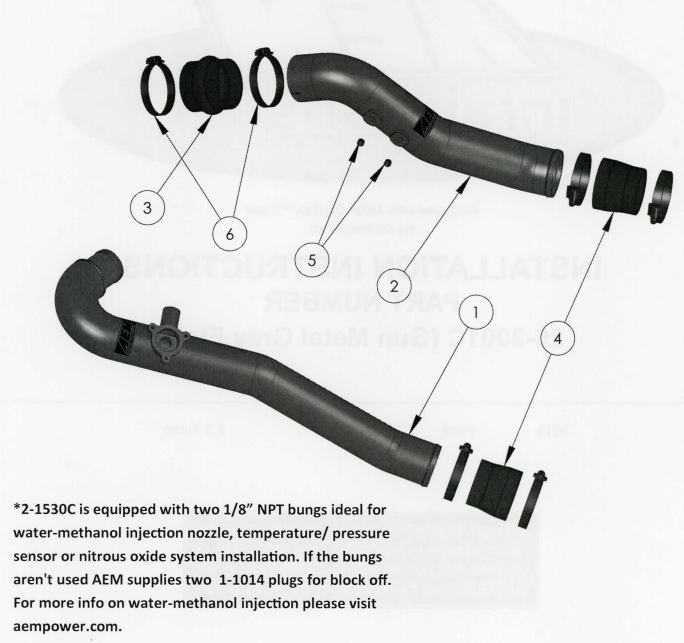

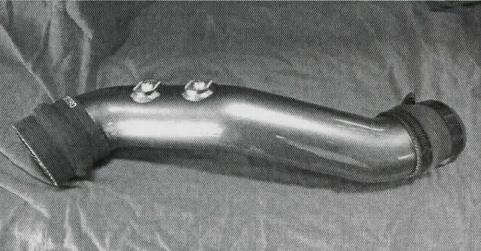

a. Assemble your new AEM cold-side charge pipe as shown according to the diagram on page 2 of this document. Exclude the upper hose clamps for now.

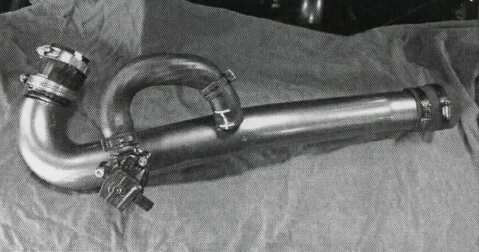

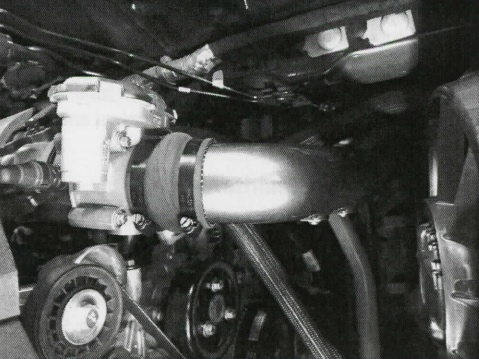

b. Assemble your new AEM hot-side charge pipe as shown according to the diagram on page 2 of this document including the factory turbo coupler and vent hose.

c. Install the cold-side charge pipe onto the intercooler first with the throttle body coupler slid all the way back onto the tube as shown above.

d. Slide the coupler over the throttle body and install the hose clamps. Ensure that both couplers have adequate engagement of all mating surfaces.

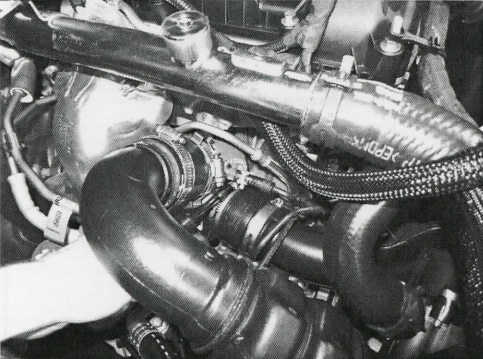

e. Install the hot-side charge pipe assembly onto the turbo outlet and intercooler inlet simultaneously. En-sure that both couplers have ade-quate engagement at the sealing sur-faces. The hose clamps should fit en-tirely onto the coupler and behind the seal-bump features of the pipe. Rein-stall the intake system and reconnect the vent hose from the recirculation valve to intake tube being sure to fully engage the spring clamps.

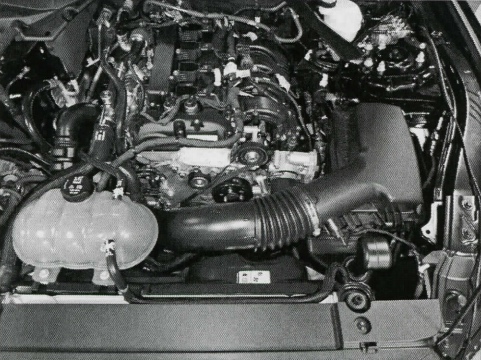

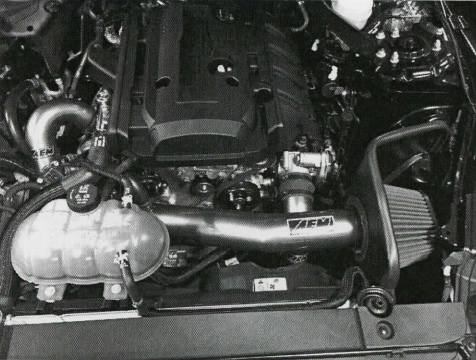

Factory charge plumbing system.

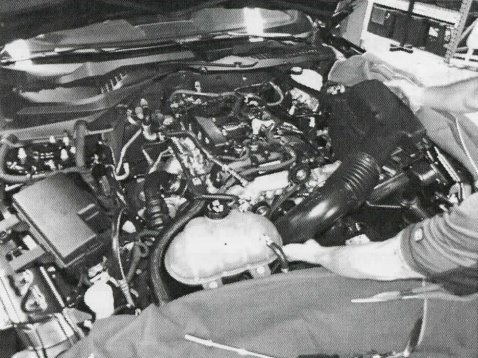

Finished installation of AEM Charge Pipe System (shown with AEM Intake System 21-740C.)

4. Reassemble Vehicle

a. Position the tubes and couplers for the best fitment. Be sure that the tube or any other components do not con-tact any part of the vehicle in appropriately.

b. Check for proper hood clearance. Re-adjust tubes if necessary and re-tighten them. Hose clamps should be torqued to 30in-lbs.

c. Inspect the engine bay for any loose tools and check that all fasteners that were moved or removed are properly tightened.

d. Ensure that the injection plugs were securely installed into the cold-side charge pipe if no accessories are to be used there. Teflon thread sealant tape is recommended.

e. Reconnect negative battery terminal and start engine. Let the vehicle idle for 3 minutes. Perform a final inspection before driving the vehicle.

5. Service and Maintenance

a. AEM Induction Systems requires cleaning the intake system's air filter element every 100,000 miles. When used in dusty or off-road environments, our filters will require cleaning more often. We recommend that you visually inspect your filter once every 25,000 miles to determine if the screen is still visible. When the screen is no longer visible some place on the filter element, it is time to clean it. To clean, purchase our Synthetic air filter cleaner, part number 1-1000 and follow the easy instructions.

b. Use window cleaner to clean your powder coated AEM® intake tube.

NOTE: DO NOT USE aluminum polish on powder coated AEM® intake tubes.

AEM Air Intake System Warranty Policy

AEM® warrants that its intake systems will last for the life of your vehicle. AEM® will not honor this warranty due to me-chanical damage (i.e. improper installation or fitment), damage from misuse, accidents or flying debris. AEM® will not warrant its powder coating if the finish has been cleaned with a hydrocarbon-based solvent. The powder coating should only be cleaned with a mild soap and water solution. Proof of purchase of both the vehicle and AEM® intake system is required for redemption of a warranty claim.

This warranty is limited to the repair or replacement of the AEM® part. In no event shall this warranty exceed the original purchase price of the AEM® part nor shall AEM® be responsible for special, incidental or consequential damages or cost incurred due to the failure of this product. Warranty claims to AEM® must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and is nontransferable. Im-proper use or installation, use for racing, accident, abuse, unauthorized repairs or alterations voids this warranty. AEM® disclaims any liability for consequential damages due to breach of any written or implied warranty on all products manu-factured by AEM®. Warranty returns will only be accepted by AEM® when accompanied by a valid Return Merchandise Authorization (RMA) number. Credit for defective products will be issued pending inspection. Product must be received by AEM® within 30 days of the date RMA is issued.

If you have a warranty issue, please call (800) 992-3000 and our customer service department will assist you. A proof of purchase is required for all AEM warranty claims.