Best Sellers

How to Install GMS Vertical Link on your Mustang

Tools Required

- Wrenches-15mm & 17mm

- Sockets- 15mm, 18mm

- /8 Drive Ratchet and Extensions

- 21mm (1/2" drive) socket and impact gun to remove rear wheels

- Floor Jack

- 2 Jack Stands

- Anti Seize

Step 1:

Place the vehicle in a location where it will not need to be moved from the beginning to the end of this installation. Vehicle should be on a flat surface and level.

Step 2:

Raise the rear end of the car and support it from the rear sub-frame mounting pads.

Step 3:

Using a 21mm socket and impact gun or equivalent, remove the rear wheels and secure for the remainder of this installation.

Step 4:

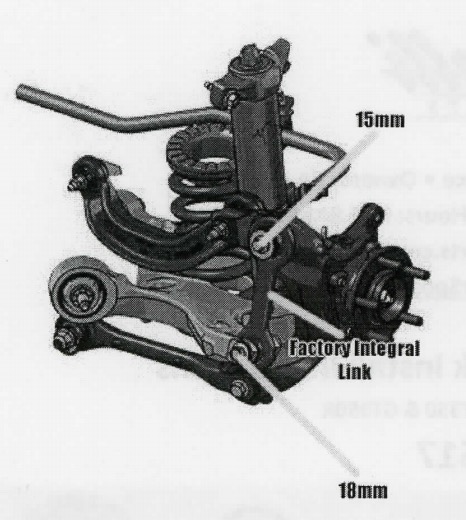

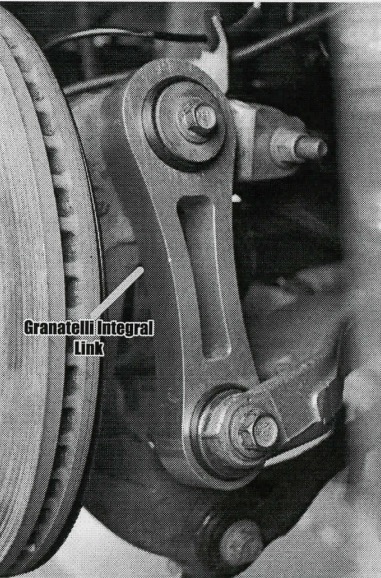

Starting from either the passenger side or driver, locate the factory integral links shown in figure 4 (red arm running perpendicular to the ground and parallel to the shock.

Step 5:

Remove the upper (top) 15mm bolt and the lower (bottom) 18mm bolt from the factory integral link. This allows you to remove the factory component as seen in figure 3 (top of page 1). Note: The upper 15mm bolt has a Ford factory nut on the back side. It has an anti-rotation clip to prevent it from spinning and should not require a tool to hold it. The lower 18mm bolt threads into the factory "H" Arm.

Step 6

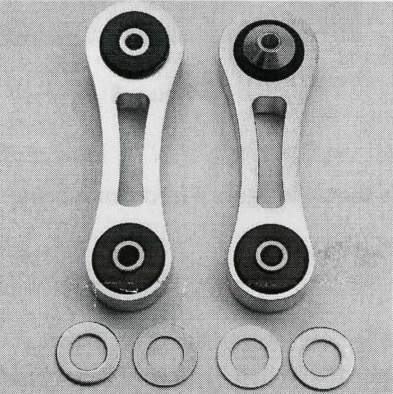

Your Granatelli Integral links should have come with (2) 1.75 diameter flat washers tied to each lower bolt hole of the new Integral Link (See figure 1). Remove the plastic tie and liberally lube both the upper and lower bushing surfaces as well as both sides of each flat washer.

Step 7:

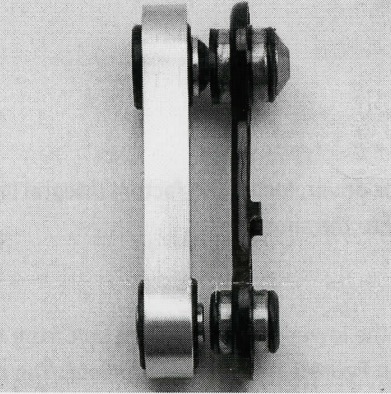

With the tapered aluminum bushing pointing up, slide the new Granatelli Integral link into place. Your first reaction will be to install the new link from the top down but we find the easiest way to install the integral link is by sliding the integral link into the center and then raising the part up into the location. This allows you to insert the taper bushing back into the upper mounting location. Aligning the lower is a little different story. Once the upper is in place and the 15mm bolt is hand tight (make sure you put the nut back on) you can use a heavy duty pry bar to align the bottom hole. Be patient it's not that hard but not so simple at first glance. You will wonder why we made this so tight. Simple, the factory integral link floats around and deflects as much as 15 degrees. The Granatelli Integral link gets rid of that problem and as such it must be tight.

Step 8:

Once you have both holes aligned and the bolts back in place, retighten to 85 ft/lbs. - Do both sides the same way.