Best Sellers

How to Install Krona Performance B.A.M.F. Catted Turbo-Back Full Exhaust System on your Mustang

Installation Time

3 hours

Tools Required

- 7/8 wrench

- 13mm wrench

- 13mm deep socket

- 13mm standard socket

- Large pliers /channel locks or exhaust hanger removal tool

- Long 3/8 extension

- 3/8 drive socket

- Antiseize

- Spray lubricant

- 15mm wrench

- 15mm deep socket

- Common Sense

www.KronaPerformace.com

2015+ Ford Mustang Ecoboost turbo back B.A.M.F. Installation Guide

Included components:

X1 Krona 3” downpipe (with or without cat)

X2 8mm 1.25 x 40 flange bolts

X1 Krona 3” to 3” downpipe adapter

X1 Clampco 3” v-band clamp

X1 3” band clamp

X1 Krona 3” to 2.50” mid pipe assembly

X2 2.50” compression clamps

X1 2.50” Left hand muffler assembly

X1 2.50” Right hand muffler assembly

Disassembly and Removal

1. Place the vehicle in a secure location and allow the vehicle to cool. Support the vehicle high enough off the ground that you can work easily under the car (please be very diligent when supporting the vehicle, you will not be able to enjoy your new exhaust system if the car falls on your head). It is best to start the removal of the factory system from the rear of your vehicle working your way forward.

2. The next step is to prepare to remove the rear mufflers from the factory exhaust hangers. Depending on how much space you have available to remove and install this system, it might be necessary to the cut stock system to remove it in two pieces (this is not recommended). If you are using a lift it is very simple to remove the entire system with the help of another person.

3. With the rear mufflers supported, take your long extension and loosen and remove the 13mm bolts holding the factory exhaust hangers on each side to the body of the vehicle. The hanger should have one bolt on the inside and outside. Once loosened, leave the factory hangers on the mufflers until it is completely removed from the vehicle. Spray some lubricant on the rubber portions as you will need to remove these and reinstall on your new B.A.M.F. Krona system.

4. Next you may remove the factory rear exhaust hangers holding the system to the rear suspension just above the differential cover(x1 13mm bolt each side). These hangers can remain on the system until it is removed from the vehicle. Spray some lubricant on the rubber portions as you will need to remove these and reinstall on your new Krona system.

5. Place a support under the factory center resonator and now loosen the factory band clamp (x2 15mm bolts) attaching the downpipe to the mid pipe/resonator.

6. All attachment points are now loose and the system is ready to be removed. Carefully guide the stock system out from underneath the vehicle. This is easily done with help from another set of hands.

7. Next remove the rubber exhaust hanger connecting the downpipe to the body of the vehicle. This is easily done with some spray lubricant and large channel locks or an exhaust hanger removal tool. Use care to avoid damaging the rubber hangar as you will be reusing it on your new Krona down pipe.

8. The secondary O2 sensor may now be unplugged and removed from under the car (7/8 wrench). This can be easily reached from under the vehicle.

9. Remove factory downpipe bracket holding it to the side of the transmission. (x2 13mm bolts) This is also an excellent time to remove the bracket from the factory downpipe (x2 13mm nuts).

10. Unplug and remove the primary O2 sensor from the top of the downpipe (7/8 wrench).

11. Your downpipe is almost ready to be removed. From the top of the vehicle, remove the two top turbo flange nuts using a 15mm deep wall socket or a 15mm wrench.

12. Moving back to the underside of the vehicle, you have one more turbo flange nut to remove using a 15mm deep socket and ratchet. We recommend supporting the rear of the downpipe prior to removal of the last flange nut.

13. Everything is now loose and your factory downpipe is ready to be removed from the underside of the vehicle. Carefully slide the downpipe out of the connection with the mid pipe (this was loosed in step 2) by pulling the downpipe. It should be relatively easy to slide free.

Installing Your B.A.M.F. Krona turbo back exhaust system

1. With your factory system completely removed you are now ready to begin the installation of your new system.

2. Before starting the reassembly of the exhaust it is very important to locate the fire ring gasket which mates the downpipe to the turbo flange. It is possible that it could stick on the turbo itself and also sometimes fall off when the downpipe is removed. Either way, it’s time to locate this piece and inspect for damage. These are easily reusable and only fit on the turbo in one direction. Re install on the turbo flange as shown.

3. Now you are ready to install your new Krona 3” downpipe (as if you weren’t ready before you started reading this novel, am I right?). From the bottom of the vehicle carefully slide the downpipe up and align it with the turbo studs. Having an extra set of hands or a stand to hold the downpipe in position makes this a lot easier for this step. Now that the downpipe is aligned with the turbo flange you will need to reinstall the factory hardware to connect the down pipe to the turbo. It is best to start each nut by hand then evenly tighten them down.

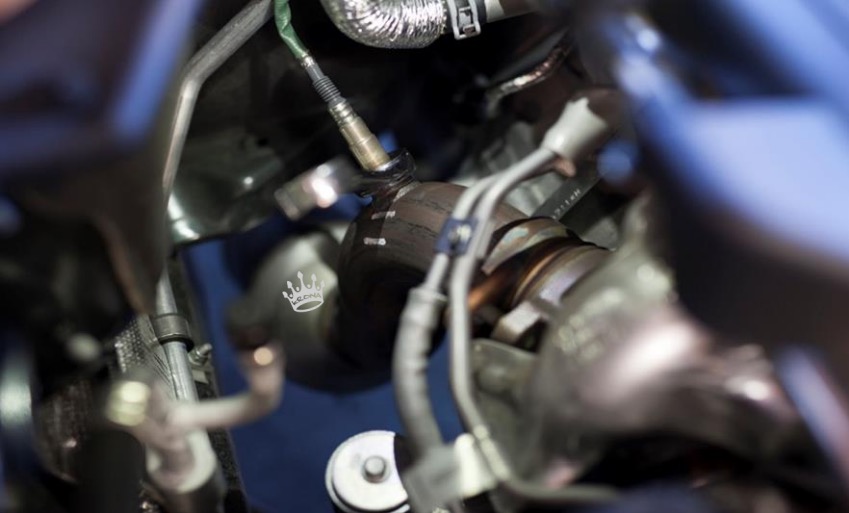

4. This is also a good time to reinstall the factory O2 sensors. Reinstall the primary O2 sensor from the top of the vehicle and the secondary O2 sensor from the bottom. We recommend applying anti-seize on the threads ONLY to help in any future removal of the sensors. Use caution to ensure that no anti-seize gets on the sensor itself as this will cause premature failure.

5. Next, reattach the downpipe bracket to the transmission and then to the down pipe. You will need to use the supplied Krona mounting bolts as the factory ones will not be long enough to reach through the Krona bracket. We recommend tightening the bracket to the downpipe prior to the transmission.

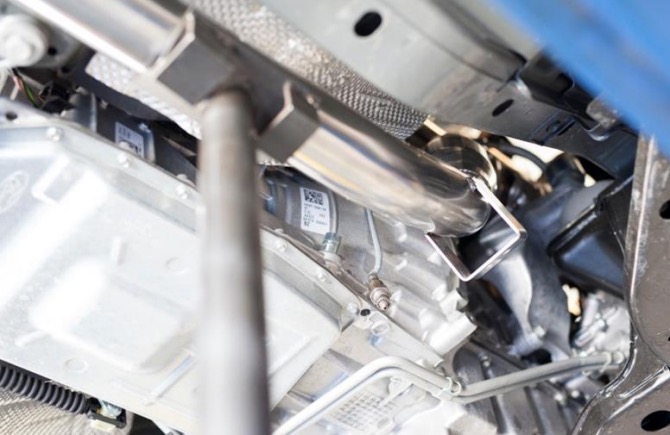

6. With the downpipe now bolted in place you may now install your 3” to 3” turbo back adapter. Before butting the two pipe ends together, slip the exhaust hanger into bracket on the adapter pipe. This process is made easier by using a generous coating of lubricant on both sides of the exhaust hanger.

7. Slide the slip fit connection together and then slide the V-Band clamp over the downpipe and index as shown. Do not tighten this connection at this time and instead make sure it is just snug enough to hold the adapter pipe in place.

8. Slide the supplied 3” band clamp over the mid pipe and then install the 3” to dual 2.5” krona mid pipe. Do not tighten the 3” clamp at this time, only ensure it is on your exhaust assembly.

9. On your removed factory system carefully remove the exhaust hangers. Ensure you do one side at a time; if you get the hangers mixed up you will have fitment issues. Install the hangers back in there factory locations beginning with the rear muffler mounts. Note to leaving the bolts loose to help in final alignment of the Krona system.

10. Install your Krona muffler sections one side at a time by sliding the metal hangers into the factory rubber hangers from the back forward. Then install the upstream hangers onto the Krona system prior to bolting them to the chassis. It is best to also leave these loose once bolted in as it will provide enough rotation to help with final alignment. This is also an excellent time to slide the 2.5” supplied compression clamp over the mid pipe section and orient as shown.

11. Slide your mid pipe back to allow for roughly a ½” gap between the connecting pipe sections. The clamp may be installed but do not tighten down at this time.

12. With both sides installed, equally adjust the distance between the connections using the clamps. Do not tighten fully at this time.

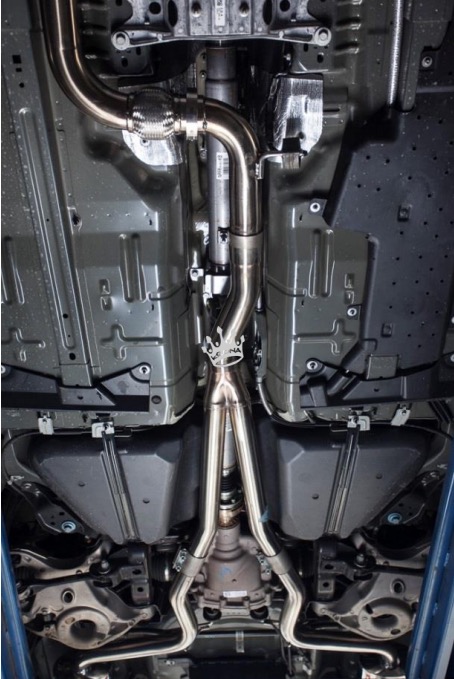

13. Now that the system is now loosely installed on the vehicle, start from the rear and work your way forward by tightening down all bolts and pipe connections. The tip section alignment/orientation is primarily dictated by the positioning of mid pipe to muffler pipe sections. Ideal fitment would leave equal spacing on all sides of the tip section

NOTE: You should have a minimum of a ¼” gap between the exhaust and body to allow for thermal expansion as the system heat cycles.

14. When tightening down all bolts and clamps working your way forward it is important to also ensure all piping in parallel to the ground. This indicates proper fitment has been achieved.

15. Tighten down the 2.5” compression clamps and then the 3” band clamp on the mid pipe section. See below for proper clamp orientation. (15mm deep socket)

16. Double check all of your connections, bolts and tip section placement. Final assembly should look as shown below.

It is almost time to go try this bad boy out!

Final Check-Off List

1. Double check that all connections are tight.

2. Ensure your O2 sensors are installed and the wiring is reconnected.

3. IMPORTANT: Wipe the system clean of all dirt, finger prints or debris using a glass cleaner, simple green or similar. Once the exhaust gets hot, any remaining dirt particles will be burned onto the finish and become permanent.

4. Start your car and check for leaks…..and to hear your new B.A.M.F. Krona Exhaust system!

5. Now go let everyone within a 30 mile radius know that you just installed the best exhaust system on the market!

Note: It is completely normal for the exhaust to smell initially and for the first couple drives. This will slowly dissipate as the system heat cycles several times.

Upon breaking the system in and the thermal expansion and contraction of the metal it may be necessary to retighten the turbo studs and exhaust band clamps.

If you have any questions or comments please feel free to send us an email: [email protected]