Best Sellers

How to Install Steeda Tri-Ax Race Short Throw Shifter on your Mustang

Installation Time

2 hours

Tools Required

- 7mm socket

- 10mm socket

- 13mm socket

- 15mm socket

- 18mm socket

- 3/8” socket

- 5/64” Allen wrench

- 3/32” Allen wrench

- 3/16” Allen wrench

- 5/16” Allen wrench

- Torque wrench

- T20 Torx bit

- 10” socket extension

- Jack and jack stands/lift

- Flathead screwdriver

- Vise grips

- C-clamp

- Pry bar

- File

- Scissors

Disassembly: Cockpit

1. Remove the panel covers in the front of the center console by hand. These are held in by clips and magnets. Figures 1 & 2.

2. Using a 7mm socket remove the 4 bolts (2 on each side) which hold the center console to the transmission tunnel. These are located in the front of the center console under the access panels which were just removed.

3. Unscrew and remove the shift knob.

4. Lift the parking brake to its highest position.

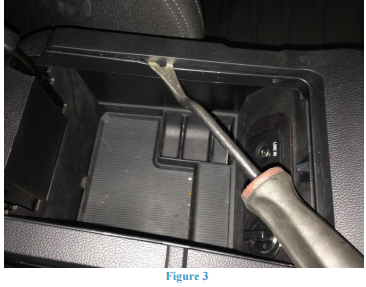

5. To remove the center console, open the center console storage area and use a flathead screwdriver to detach the plastic center console cover as shown. This is held in by 4 clips in the storage area, 2 clips on the side of the console and 2 clips on the front of the console. Once the 4 clips in the center console storage area are released simply lift up to detach the 2 clips located on the side of the center console.

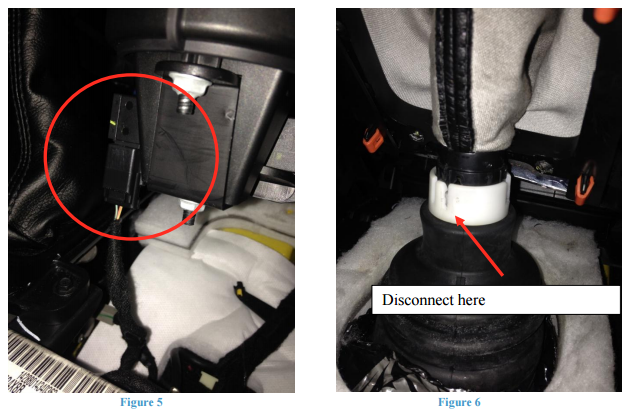

6. Detach the electrical connector underneath the cup holder and continue lifting up on the console, to disconnect it completely

7. Use a flathead screwdriver to release the three prongs holding the shift boot to the reverse lockout collar and then remove the center console completely.

8. Remove the stock sound deadening material.

9. Remove the factory rubber boot.

10. Next you must press the factory roll pin out of the stock shifter. Put the shift lever into 1 st or 2 nd gear, then put a socket on one side of the roll pin and use a C-clamp to press out the pin into the socket. The pin will not press all the way out, use vice grips to pull the roll pin out the remaining distance.

11. Once the pin is removed, remove the spring from the shifter and place the shifter in neutral.

12. Use the T20 Torx bit to remove the factory reverse lockout collar.

Disassembly: Underbody

1. Jack up your car and place it on jack stands, if possible use of a lift is suggested.

2. Once your car is in the air, place a support under your transmission, a floor jack will work well for this.

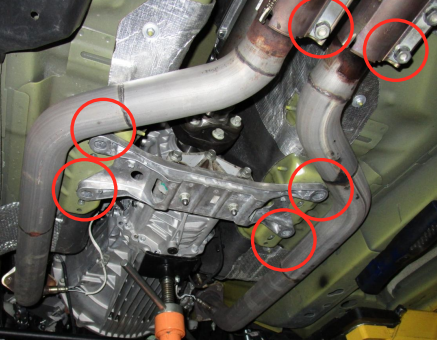

3. Using a 15mm socket remove the 4 nuts which clamp the exhaust sleeves in place. Slide these out of the way to allow your exhaust to drop down. Note: Before proceeding further, mark the driveshaft position relative to the flex coupler with a paint pen.

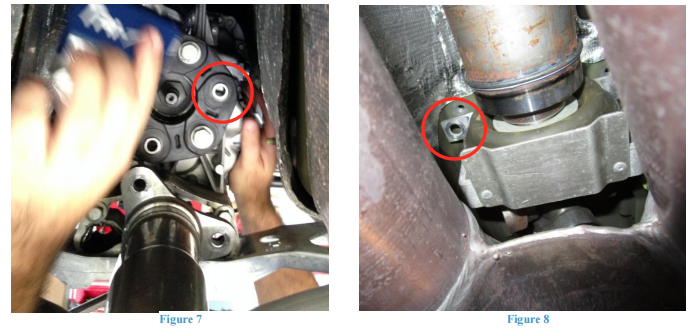

4. Using a 15mm and 18mm socket remove the 3 mounting bolts which hold the driveshaft to the flex coupler. Then let the driveshaft hang

5. Using the 10” extension and 10mm socket, remove the two bolts which secure the rear shifter mount and bushing. Remove this bracket and bushing from the car.

6. Make sure your transmission support is secure; using an 18mm socket remove the 4 bolts which secure the transmission mount to the chassis.

7. Next using the 10” extension and the 13mm socket, remove the drive shaft center bearing bolts and let the driveshaft droop.

8. Lower the transmission 3-4” relative to the chassis so that you can gain more clearance to access the bolts on the top half of the transmission.

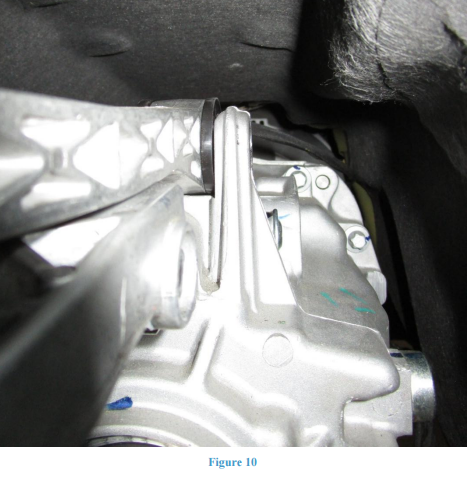

9. On the upper side of the transmission, remove the 10mm bolt holding the shifter arm in place. Once removed, swing the mounting arm up and to the side so as to access the shifter linkage bolt.

10. Using a ¼” drive 13mm shallow socket remove the bolt which holds the stock shift linkage to the shift shaft on the transmission. The shifter will now be free to remove.

11. The shifter can be removed on either side of the driveshaft, if you are having a particularly difficult time some light pressure with a pry bar on the driveshaft will help give you the clearance you need.

Disassembly: Stock shifter

1. Using a 3/8 inch socket remove the 4 bolts on the bottom plate of the stock shifter. Remove the stock shift linkage from the assembly and detach the stock bushings from this linkage.

2. Using the 3/8 inch socket remove the two bolts holding the stock pressure plate to the shifter housing.

3. Remove the stock shifter from the assembly.

4. Disassemble the stock shift lever and keep the following pieces: bottom black pivot cup, main shift ball pivot cup, and the factory shift linkage.

Assembly: Steeda shifter

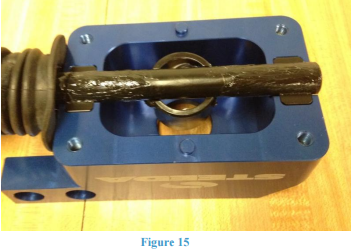

1. First we will assemble the bottom half of the shifter. Inspect the stock shifter linkage for any weld slag left on the shaft from the welding of the stock pivot cup. If any slag is present take a file and file until smooth, verify with your fingers that no raised protrusions remain. Note: Weld slag on these linkages is not common however it is possible. The Steeda shifter utilizes a wider than stock bushing spacing and so any weld slag on the factory linkage should not interfere with its operation as long as it did not interfere with the stock shifter’s operation.

2. Carefully open the supplied grease pack at the tip using scissors; lightly and evenly grease the stock shift shaft as shown. Also lightly grease the inside of the stock steel pivot cup. Make sure to save this grease pack as you will need it later.

3. Place the stock shift linkage into the slide rail bushings on the mid plate and bolt the bottom plate to the middle plate using the four ¼” x ¾” long socket head cap screws to secure the shifter linkage

4. Make sure the two ¼ -28 bolt holes on the bottom plate are facing the rear of the assembly when bolting this assembly together. Purple Loctite 222 is recommended for use on these bolts. Note: A small amount of clearance is present between the slide rail bearings and the shift linkage rod. This is to account for heat expansion and the factory tolerances. This ensures smooth easy shifts every time.

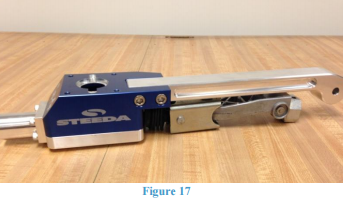

5. Install the main mounting arm using the supplied 3/8 bolts. Purple Loctite 222 is recommended for use on these bolts.

6. Install the Steeda tail stock using the four ¼”-28 x ¾” long socket head cap screws. Purple Loctite 222 is recommended for use on these bolts.

Assembly: Installing the shifter in the car

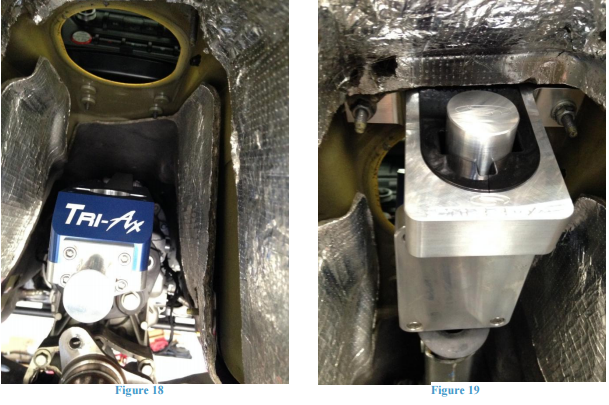

1. Using the ¼” drive 13mm shallow socket attach the shift linkage to the transmission shift shaft.

2. Insert the main arm of the Steeda shifter into the transmission mount and tighten the factory 10mm bolt.

3. Next take the Steeda bushing and bracket and ensure the bushing is seated down fully into the bracket. Slide the bushing and bracket onto the tail stock of the Steeda shifter, make sure that there is minimal or no gap present at the clearance slot of the Steeda bushing when slid onto the shaft. This gap will be eliminated when the bracket is tightened to the chassis.

4. Using the 10” extension and 10mm socket tighten the factory nuts which mount the Steeda bushing and bracket to the chassis. Blue Loctite 246 is recommended for use on these nuts.

5. Raise the transmission using your floor jack and secure the transmission mount to the chassis using the 4 factory bolts and the 18mm socket. Torque to 46 ft-lbs.

6. Mount the driveshaft center bearing to the chassis using the factory hardware. Torque to 35 ft-lbs.

7. Line up the paint marks you previously used as indicators between your driveshaft mount and the flex coupling. Make sure these line up before bolting them together in order to avoid any unwanted imbalances in the driveshaft at speed. Using the 15mm and 18mm sockets bolt the driveshaft to the flex coupler and torque to 81 ft-lbs.

8. Re-align the exhaust tubes and slide the clamp sleeve over both ends. Using the 15mm socket tighten the 4 nuts on the flange to 35 ft-lbs.

Assembly: In cockpit

1. Using the supplied grease pack, lubricate the main shifter ball and the smaller secondary ball of the Steeda shift lever generously.

2. Install the main factory pivot cup and the smaller black pivot cup onto the Steeda shift lever.

3. With the car in neutral slide the factory black pivot cup into the black steel pivot cup on the shifter linkage. Also press the factory main pivot cup into the pivot cup seat on the mid plate. Make sure it is fully seated against the bottom face of this seat. Also make sure that the shift lever has the threaded bolt hole for the reverse lockout facing the passenger side of the vehicle as shown.

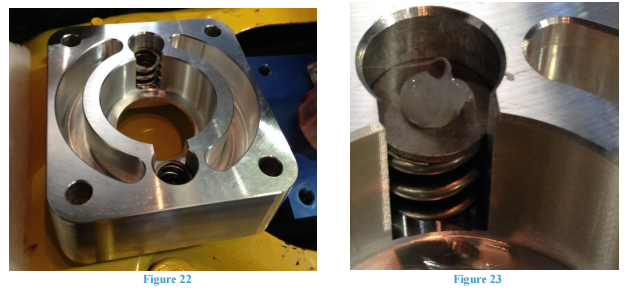

4. Install either pair of supplied Steeda springs into the top plate as shown. The shorter springs have a medium centering stiffness whereas the long springs have a firm centering stiffness. These springs can be interchanged to fit your driving style and preference.

5. Once the springs are seated in the guides on the top plate, install the spring shims on top of them and then place a small amount of supplied grease on the shims. This will help aid in smooth operation with the cross pin on the shift lever as well as hold the springs in place when installing the top plate. If the grease is not applied, the springs and spring shims may fall out during installation and the spring shims may not seat flush when installed.

6. Install the top plate onto the Steeda shifter by sliding it over the shift lever and bolting it to the mid plate using the supplied four ¼”-28 x 1 ½” long socket head cap screws. Before bolting this down make sure the reverse lockout stop is oriented on the driver side of the shifter.

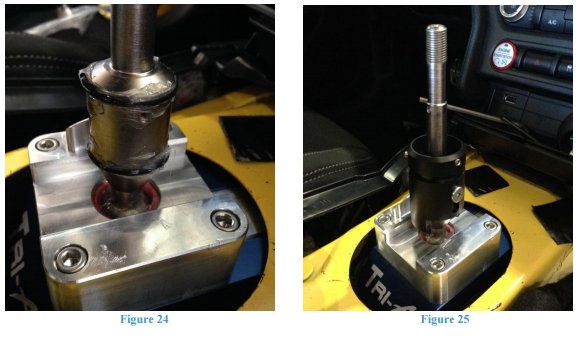

7. Install the two supplied O-rings into the grooves on the shift lever.

8. Lubricate around the entire perimeter of both O-rings making sure to get grease on both the top and bottom faces of the O-rings as shown.

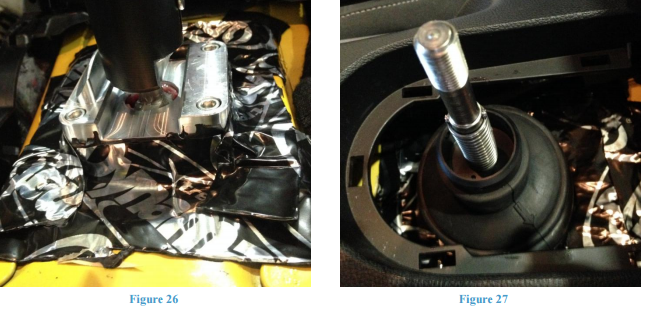

9. Install the Steeda reverse lockout collar orienting it so that the vertical slot aligns with the Torx bolt hole. Do not apply Loctite to this bolt as it could prevent smooth operation of the reverse lockout collar.

10. Slide the spring over the shaft of the shift lever and install the two supplied 4mm x 0.8 set screws into the shift lever. Make sure both are spaced equally in the threaded holes and tighten them down firmly.

6. Install the top plate onto the Steeda shifter by sliding it over the shift lever and bolting it to the mid plate using the supplied four ¼”-28 x 1 ½” long socket head cap screws. Before bolting this down make sure the reverse lockout stop is oriented on the driver side of the shifter.

7. Install the two supplied O-rings into the grooves on the shift lever.

8. Lubricate around the entire perimeter of both O-rings making sure to get grease on both the top and bottom faces of the O-rings as shown.

9. Install the Steeda reverse lockout collar orienting it so that the vertical slot aligns with the Torx bolt hole. Do not apply Loctite to this bolt as it could prevent smooth operation of the reverse lockout collar.

10. Slide the spring over the shaft of the shift lever and install the two supplied 4mm x 0.8 set screws into the shift lever. Make sure both are spaced equally in the threaded holes and tighten them down firmly.

11. Using scissors cut 4 strips of Dynamat approximately 6 inches long by 2.5 inches wide. Place them on the four sides of the top plate and transmission tunnel, sealing the transmission tunnel from any potential noise disturbances. Make sure no gaps or holes exist between your Dynamat layers, this step is extremely important in providing an NVH-free shifter. More Dynamat can be installed as desired, however make sure to avoid getting this material in any bolt holes or on the reverse lockout stop.

12. Install the white factory sound deadening material over the Dynamat and shifter.

13. Install the factory rubber boot over the shifter; stretching it over the top plate (can be secured with a zip tie if desired). The top of this boot needs to sit flush inside of the lockout collar groove. Figure 28. 14. Align the center console cover over the center console and shifter. Press the factory reverse lockout and boot down into the Steeda reverse lockout collar (this is a snug fit). Then tighten down all three set screws in the Steeda reverse lockout collar. Make sure you tighten these down evenly around the reverse lockout otherwise you may experience some noise. These set screws should all sit flush in the Steeda reverse lockout collar when complete.

15. Re-install the center console cover and make sure you plug back in the electrical connector under the cup holders (the car will not start if you don’t). This will simply snap back into place.

16. Install the supplied rubber chord into the threaded hole in the factory shift knob.

17. Screw the factory shift knob down onto the Steeda lever. Tighten down firmly until your shift knob aligns with the reverse lockout collar properly. Make sure not to over tighten this piece as the plastic shift pattern emblem in the stock knob can pop out.

18. Re-install the four bolts which hold the front of the center console to the transmission tunnel using the 7mm socket.

19. Snap the front center console access panels back into place.

Your Steeda Tri-Ax Race Shifter is now ready for action!