Perhaps the most important operating system of any vehicle is the brake system. Yes, the engine and drivetrain mobilize a vehicle but without any way of stopping, they are just fast tracks to disaster. In third-generation Challengers (2008-2018), you have pretty beefy power plants and the capability to get going really fast. Every pony on the hood makes it more important to understand, maintain and even upgrade the brake system whenever possible.

Contents

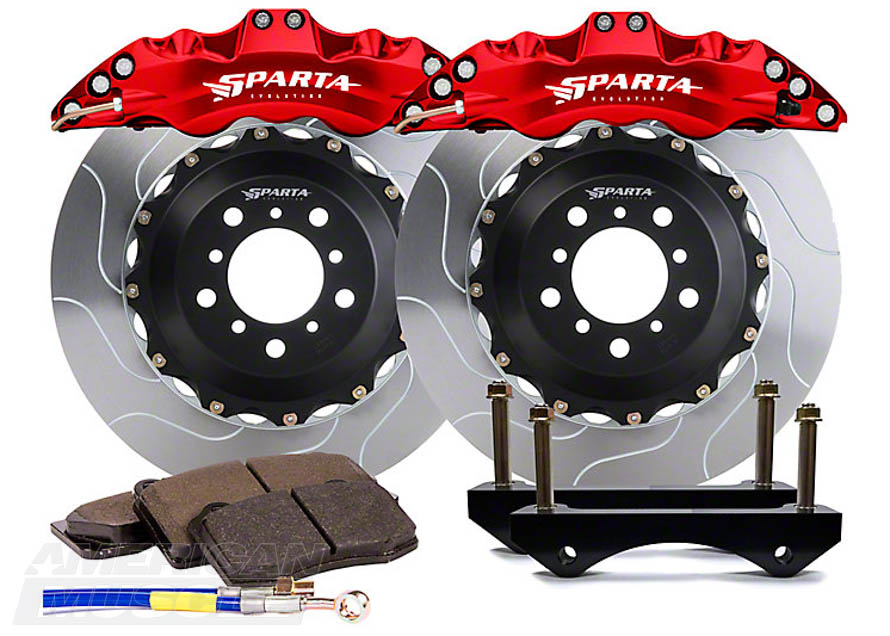

Shop Challenger Brake Parts

Upgrading your horsepower is one thing, but if you can't bring your Challenger to a stop all that power means nothing. Making sure your brakes can keep up with your engine mods should be a priority in any build. Better quality pads, more efficient rotors, and more will do the job.