Best Sellers

How to Install a B&M Hammer Console Rachet Shifter - Automatic on Your 1987-1993 Mustang V8

Shop Parts in this Guide

Installation

The B&M Mustang ConsoleHammer shifter is a full ratchet shifter that is designed to fit 1987 to1993 Ford Mustangs with AOD automatic transmissions. Unlike other Hammer shifters, this shifter not only ratchets between all of the forward gears but also ratchets into Reverse and Park. It has a lockout, controlled by the trigger, to keep from unintended shifts into Reverse or Park.

It is designed to work with the ignition interlock and brake interlock installed in these vehicles. This shifter is designed to work with the existing Ford shifter cable and the existing Neutral safety switch and back up light switch.

If your car has C-4 transmission installed in place of the original AOD transmission, you will need to purchase conversion kit #81020 in addition to this shifter. This kit includes a shifter cable and transmission cable bracket and shift lever for a C-4 or C-5 transmission.

Please read the instructions and review the illustrations thoroughly before beginning the installation. The mechanical components of this shifter are precision made and assembled at our factory. Any modification or disassembly of these parts can cause the shifter to malfunction and will void the warranty. You should disassemble only those items outlined in the instructions.

IMPORTANT: This shifter is designed to work with the steering column lock on your car. Be sure that it is connected to the shifter and properly adjusted, so that the steering column only be locked and the key removed when the shifter is in Park and so that the transmission cannot be shifted out of Park unless the key is turned on. Some Mustangs also are equipped with a brake interlock that prevents the shifter from being shifted out of Park unless the brakes are applied. If your vehicle is so equipped, this feature will also work with the B&M Mustang ConsoleHammer shifter. Check to be certain that the interlock operates correctly with the existing shifter. If it does not, it probably will not work with the B&M Mustang Console Hammer. The interlock should allow you to turn the key to the locked position only when the shifter is in Park, and will not allow you to shift out of Park unless the key is turned out of the lock position(and the brakes are applied if your vehicle also has a brake interlock).

The vehicle should be about 2feet off the ground for ease of installation.

Use jack stands, wheel ramps or a vehicle lift. Make sure the vehicles firmly supported before attempting to work on it.

INSTALLATION

STEP 1.Remove the console. First remove the square panel around the stock shifter. It is held in by four spring clips. Pry it up with a screwdriver. Then remove the folding center armrest if your car has one. The armrest is held in by two screws on each side under oval covers on each side of the console. Next remove the cover plate over the parking brake that contains the ashtray. This is secured by four screws, two at the front and two at the rear. Disconnect the wiring to the cigarette lighter and the power mirrors. Remove the radio. If it is the factory radio there are the two small holes on each side of the radio front plate. Put a 1/16” diameter rigid wire in each of these holes and push them outwards to release the clips that secure the radio. Most after market radios have screws on the front or under a removable coverplate that secure the radio. Pull out the radio and anything else in that area of the console. Disconnect the antenna and wiring. Push inwards on both side of the glove box bin so that it will drop all the way down. Disconnect the wiring to the trunk release button and/or the gas cap cover release button if there is one. Remove the bezel around the heater controls. Put your fingers inside the rim and pull it out. Remove the bottom portion of the steering column cover, it is held on by screws. Remove the lower panel on the driver’s side of the instrument panel. On early cars it is plastic and is secured by screws on the bottom and snaps at the top. On later cars it is a padded cover that snaps in place over a sheet metal stamping that is screwed in place. You can now get to the six screws that hold in the console in place. There two at the back that screw into a bracket on the tunnel. At the front there are four screws, two on each side that screw into the dash board. After removing the screws, remove the console and set it aside. Disconnect any other wiring that may be necessary.

STEP 2.From under the car disconnect the shifter cable from the shifter. The end of the cable snaps over a ball fitting on the shifter lever. This can be pried off with a screwdriver. The cable housing is attached to the shifter flange by two screws. Move the cable end away from the shifter so that it will not interfere with removing the shifter. Inside of the car disconnect the interlock cable from the shifter. This is the 1/4” diameter black cable that goes from the front of the shifter under the dash board up to the steering column. Disconnect the center wire from the plasticbell crank by carefully pulling up on it. It will snap out. Be careful not to bend the wire. The housing of the interlock cable is attached to the front of the shifter base plate with a screw and to the end of the pivot pin for the interlock bell crank with a clip. Remove both of these and disconnect the cable.

STEP 3.Remove the stock shifter. It is held in by four screws that go into nuts that are clipped over the edges of the opening in the tunnel. If any of the sealing gasket sticks to the tunnel, remove it. Peel the paper facing off of the supplied foam rubber gasket and stick it to the bottom of the B&M shifter being sure that the holes line up. Be sure that the four nuts that are clipped around the opening in the tunnel line up with the holes. Install the shifter and screw it down with the original screws. You will have to work the right hand edge of the shifter under the edge of the carpet.(If the original screws and nuts that hold the shifter to the tunnel cannot be reused, replace them with 5/16”X 1” bolts, nuts and lock washers. Someone will have to be under the car to hold the nuts while they are tightened from the top.) Screw the jam nut and T-handle onto the end of the shifter stick to make it easier to shift during the adjustment procedures.

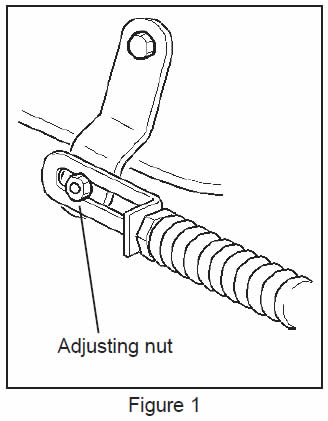

STEP 4.Before connecting the shifter cable to the shifter, loosen, but do not remove, the adjusting nut at the front end of the shifter cable where it connects to the transmission shift lever. See figure 1. Move the transmission shift lever as far back as it will go, and then move it forward three clicks. This is the Neutral position. Move the shifter to the Neutral position. (See the Operation section at the end of these instructions.)Connect the cable to the REAR side of the cable bracket on the shifter using the two self tapping 1/4” X 5/8”screws provided with the kit. Snap the cable end over the ball on the shifter output lever. Tighten the adjusting nut on the shifter cable.

STEP 5.Check that the shifter is in the Neutral position. The transmission should also be in the Neutral position. With both the shifter and the transmission in the Neutral position, loosen the adjusting nut on the trans-mission shift lever at the front end of the shifter cable. Pull forward lightly on the cable to take up the free play in the cable and then tighten the nut while still maintaining tension on the cable. Check that the shifter will move to all the gear position without having to use excessive force. (See the Operation section at the end of these instructions.) Particularly check that the transmission lever moves to the Reverse position when the shifter is moved from Park to Reverse. If it does not, recheck the cable adjustment procedure above. If your shifter cable is well used it may have developed too much free play to work with this shifter. In that case you will need to replace it with a new Ford cable.

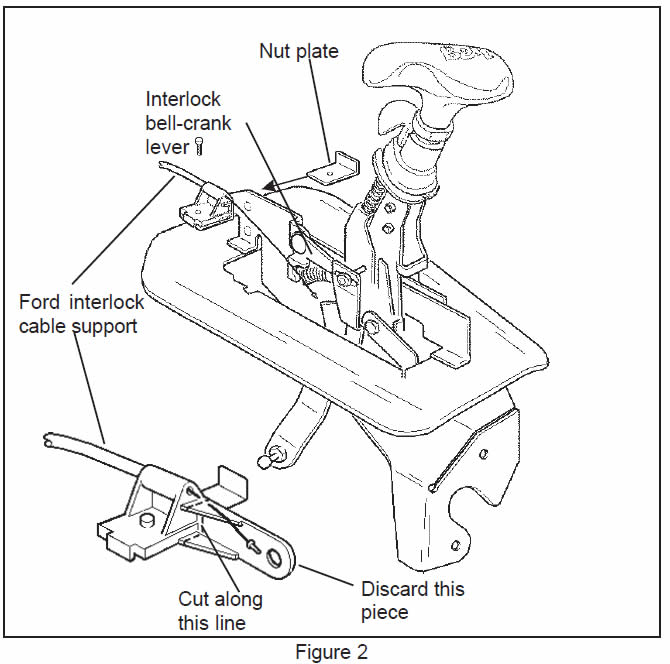

STEP 6.Turn the ignition key to the unlocked position, one notch clockwise from the locked position, and put the shifter into Park position before installing the interlock cable. Cut the end off of the plastic interlock cable support as shown in figure 2.Slip the end of the center wire of the interlock cable into the slot in the interlock bell crank. Attach the cable housing to the base of the shifter using the supplied socket head 10-24 x 1/2” screw and nut plate. See figure 2. Do not tighten the screw all the way, leave it loose enough so that cable will slide back and forth in the slot.

STEP 7.Pull up the trigger on the shifter and ratchet it back one position into Reverse. Slide the interlock cable housing as far forward as it will go and tighten the screw holding the cable to the shifter. The shifter should now be able to be shifted to all positions. The ignition key should not be able to be turned to the locked position and the key removed in any shifter position except Park. With the key in the locked position or removed, you should not be able to pull the trigger on the shifter up far enough to be able to shift into reverse. When the key is turned to the unlock position, the trigger should be able to be pulled up and the shifter be able to shift into Reverse. If your car has a brake interlock system as well, you will have to apply the brakes as well as turning the key to the unlock position to be able to lift the trigger far enough to shift out of Park. If the interlock does not operate correctly, slide the cable backwards about 1/16” and retry. With small adjustments in the position of the cable you will be able to get the interlock to operate correctly. Once the interlock is operating correctly tighten the screw to keep the cable from moving. You cannot get to this screw once the console is installed.

STEP 8.Locate a wire in the console area that is hot anytime the ignitions turned on, and is off when the ignitions off. The power feed to the radio is a possible choice. This wire will supply the current for the LED gear position indicator. The LED must be illuminated when the ignitions on, because this is the only indication of what gear position the shifter is in. Do not use the wire that was originally used to illuminate the indicator on the stock shifter, since this is hot only when the lights are turned on. When you identify the hotwire splice in a length of wire long enough to reach the shifter plus about 12”. Also run another piece of wire to a good ground. Be sure the ignition is off when splicing the hotwire and tape over the splice.

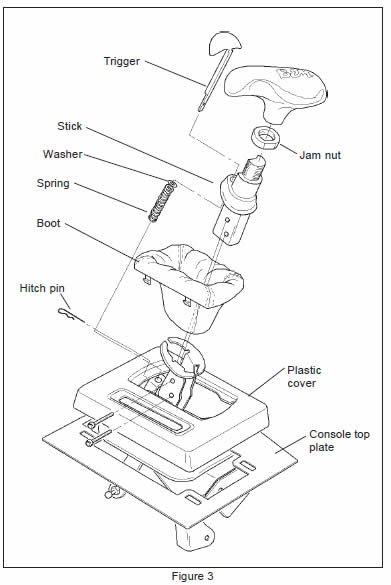

STEP 9.Before replacing the console, the stick must be removed from the shifter. Shift the shifter to the Neutral position. Remove the stick and trigger from the shifter. Remove the hitch pin that secures the trigger to the mechanism. Remove the trigger, the trigger spring and the washer on top of the spring. Remove the two screws that secure the stick to the shifter and remove the stick. See figure3.Replace the console. One of the cross bars on the console may hit the stamped part of the shifter stick. If it does, push the lower portion of the stick back to give enough clearance. Replace the six screws that secure the console to the tunnel and dashboard. Replace the cover plate over the hand brake. Reconnect any wiring in this area. Bring the two wires for the LED gear position indicator out the top of the console next to the shifter.

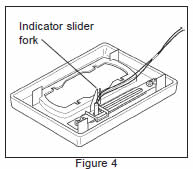

STEP 10.Put the black painted console top plate into the slots in the console. Do NOT put the steel spring clips onto the tabs. With the ignition off, connect the red wire of the LED indicator to the hot wire and the black wire to the ground wire that you prepared in step 8. Check that the LED is illuminated when the ignition is turned on. Put the plastic cover into the slots in the steel console top plate, do not put the spring clips on the tabs at this time. The fork on the indicator slider must be put over the brass indicator drive pin on the shifter. See figure 4. Snap the indicator window into the opening on the top of the plastic cover with the “P”forward. Shift the shifter between Neutral and Low and see that the LED moves when the shifter is moved. Sitting in the driver’s seat check to see if the LED lines up with the letters on the indicator. If they do not line up, loosen the nut on the indicator drive pin and move the pin until the LED is in alignment with the letters on the window.

STEP 11.Remove the plastic cover. Lift up the steel console top plate and put four of the supplied spring clips onto the four tabs on the top plate. Replace the top plate on the console and snap the clips into the slots. Locate the wires to the LED so that they are out of the way of the mechanism. Put the other four spring clips on the four tabs on the plastic cover and snap the cover into the top plate, being sure that the slider fork fits back over the brass drive pin. Install the leather boot. Turn the boot inside out and slide it over the bottom of the stick. Put the stick backing place on top of the mechanism, re-install the two screws and tighten. Slide the trigger back through the stick, the washer, the spring and the steel trigger plate on the shifter. Reinstall the hitch pin. Pliers are the best tool for this installation. See figure3. Turn the boot right side outland snap the boot into the top plate. Install the T-Handle and jam nut. The jam nut is a round nut with two flats on it. The chamfered side goes down. Tighten the jam nut when the handle is properly oriented. Use a little Loctite on the threads to keep the handle from turning. Check the operation of the shifter, indicator and interlock.

STEP 12.Replace the remaining parts of the console and reconnect the wiring.

OPERATION

The B&M Mustang ConsoleHammer is a ratchet shifter. You push the stick forward for up shifts and pull it back for down shifts. The ratchet shift allows firm, positive, no-miss upshifts and downshifts. Move the knob forward or backwards as far as it will go to select the next gear.

Then let the spring return the stick to the central position. After you shift from Drive to Neutral the reverse lockout prevents the shifter from shifting any further (to prevent accidental selection of Reverse). To shift to Reverse lift the trigger up as far as it will go and then push the handle forward and release it. When you shift from Reverse into Park, the spring pushes the trigger back down.

To shift out of Park to Reverse or another gear it is necessary to lift the trigger first and then pull back on the handle. From reverse you can continue to ratchet backwards to Neutral and any of the forward gears.

Normally it is difficult to manually control the shifts of the AOD automatic transmission, since the Low gear position controls both first and second gears, and the gating of the stock shifter does not lend itself to easy control. With the B&M Mustang Console Hammer shifter this controls very easy:

Before starting move the shifter to the Low position, ratcheted all the way back.

Leave the shifter in Low to accelerate in first gear.

When it is time to shift to second gear shift the transmission to Drive and then directly back to Low. This lets the transmission shift to second gear but holds it in second. With the B&M Mustang shifter you shift from Low to Drive and back to Low by pushing the shifter handle forward and then pulling it all the way back rather than letting the spring return the handle to the center position. After you pull it back, let go of the handle so that the spring will return it to the center position.

For the second to third shift, push the handle forward to shift into Drive and let the spring center the handle.

For the third to fourth shift, push the handle forward to shift into Overdrive and let the spring center the handle.

Shifted this way the B&M Mustang Console Hammer shifter gives much better control over the AOD transmission than any other available shifter.

Best Sellers

Related Guides

-

Installation

-

Installation

-

Installation