Best Sellers

How to Install Hurst INDY Shifter - MT-82 on your Mustang

Shop Parts in this Guide

WORK SAFELY! For maximum safety, perform this installation on a clean, level surface and with the engine turned off. Place blocks or wedges in front of and behind both rear wheels to prevent movement in either direction.

CAUTION: To avoid any possibility of bodily injury or damage to vehicle, do not attempt installation until you are confident that the vehicle is safely secured and will not move.

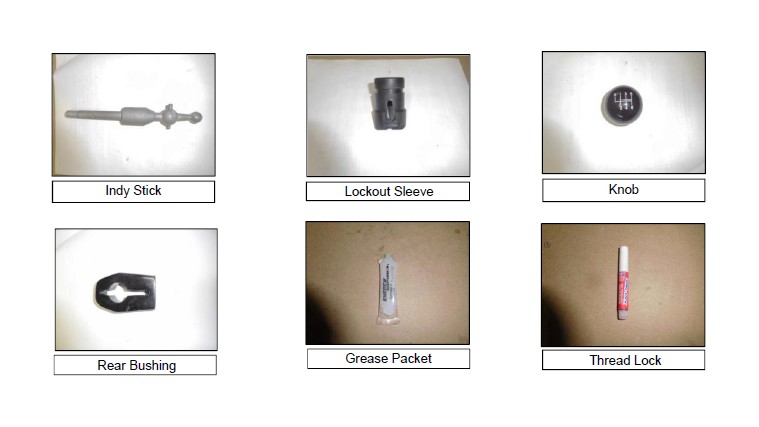

PARTS

2. Remove the front driver side and passenger side panels from the center console.

Tool: Plastic Trim Remover

3. Remove the two (2) screws from both sides of the console.

Tools: 7mm Socket, Extension, Ratchet

4. Unsnap the shift boot bezel from the console. Lift from the top to release the top clips and then use the pry tool to un-clip the rest.

Tool: Plastic Trim Remover

5. Remove the center console. Start by releasing the locking tabs at the rear of the console while working your way forward.

Tool: Plastic Trim Remover x 2

6. Unplug the harness from the console and set the console aside.

7. Remove the shift boot. There are three clips holding the boot to the reverse lock out sleeve, use a screw driver to pry one clip at a time while pulling up on the boot. Set the boot aside for reinstallation later.

8. Once the rubber boot is removed continue by removing the plastic ring and the rubber O-ring. The plastic ring and rubber O-ring will be re-used .

9. Remove the spring retaining roll pin and the spring. The spring will be reused.

Tools: 4mm Punch, Hammer

10. Remove the retaining screw and then remove the factory reverse lockout sleeve and rubber boot. The retaining screw and rubber boot will be reused.

Tool: T20 Torx Driver

11. Lift the vehicle. Support the vehicle with Jackstands if working with a floor jack.

12. Although this step is not required it makes for ease of removal and installation. Support the mid-section of the exhaust. Loosen the nuts at the two exhaust connections just behind the transmission. Move the system to the rear and let the system hang in place.

Tools: 15mm socket

13. Support the transmission.

Tools: transmission stand or floor jack

14. Remove the four (4) 18mm bolts securing the transmission to the frame. Lower the rear of the transmission. Support the rear with a transmission stand if you have the vehicle supported with a lift; support the rear with a floor jack if you have the vehicle supported with jack stands.

Tools: Breaker Bar, 18mm Socket, Ratchet, Extension

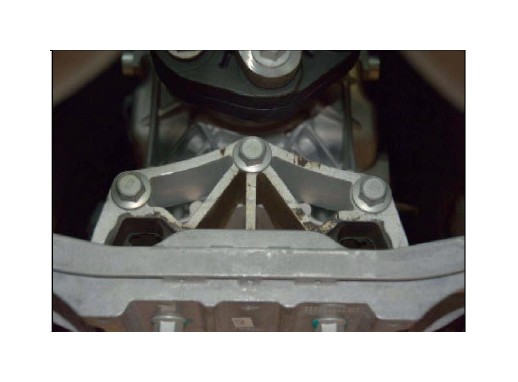

15. Remove the three (3) 15mm bolts securing the crossmember to the transmission.

Tools: Breaker Bar, 15mm Socket, Ratchet

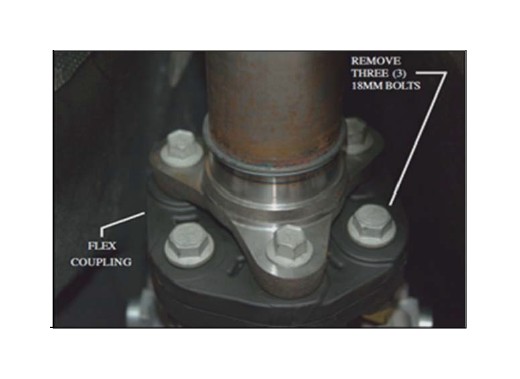

16. Remove the three (3) 18mm bolts securing the front end of the driveshaft to the transmission.

IMPORTANT: Make an alignment mark between the Flex Coupling and the transmission flange. You must re-install the driveshaft in the same position as it was removed.

Tools: 18mm Socket, Ratchet

17. Remove the center bearing bolts.

Tools: 13mm Socket, Ratchet

18. Once the center bearing bolts have been removed, you can pull the driveshaft back and lower the front end of the driveshaft. Allow the driveshaft to rest on top of the exhaust.

19. Remove the two (2) 10mm hex nuts that mount the rear of the shifter to the transmission tunnel.

Tools: 10mm Deep Socket, Universal Adapter, Extension(s), 1/4” Drive Ratchet

20. Remove the bolt attaching the shifter housing to the transmission.

Tools: a 10mm ratchet wrench makes for ease of removal.

Remove the bolt from the side of the transmission. You may have to pull down on the transmission to allow the screw to clear the tunnel.

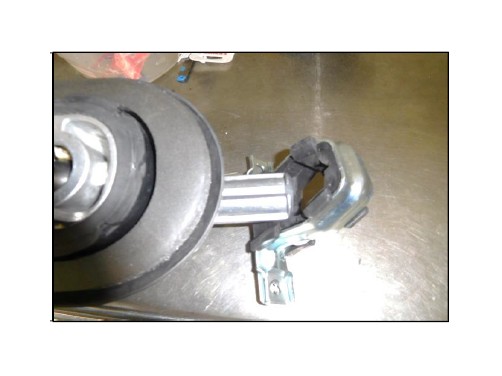

21. Remove the shift linkage bolt.

Tools: 13mm Socket, 3/8” Drive Ratchet

22. The photo to the right is a close up of the bolt removed from the shift linkage. Note that the bolt is only partially threaded at the top. This is being mentioned so you don’t spend too much time trying to loosen a bolt that is already completely loose. After it is completely loose, it will need to be pulled free.

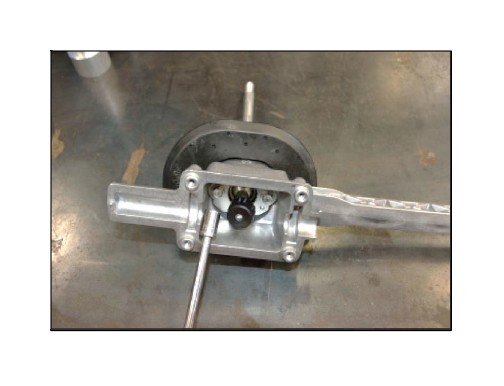

23. The shifter housing assembly can now be removed. Remove the factory rear mount from shifter housing.

24. Place the shifter housing on a clean surface.

25. Remove the rubber boot from the shifter housing.

26. Remove the (4) 10mm bolts securing the bottom plate to the shifter housing.

Tools: 10MM Socket

27. Remove the bottom Plate. Take care when removing the bottom plate, there is a rubber gasket that will be reused.

28. This is a photo of what the internal components of the shifter look like.

29. Remove the shift rod from the shifter housing.

30. Remove the shifter retaining plate from the bottom of the shifter housing.

Tools: 10mm Socket, Extension, Ratchet

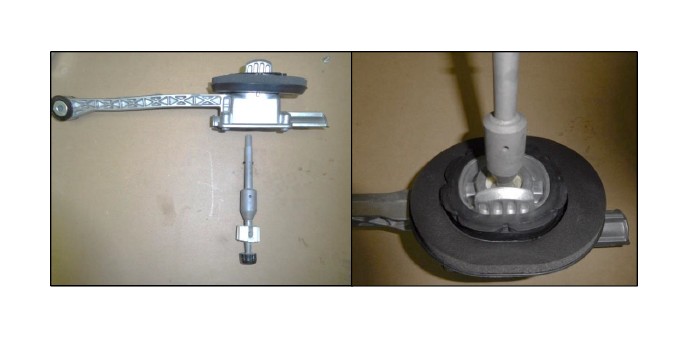

31. Remove the shifter from the housing and disassemble. Use a set of pliers to pry the small pivot cup off of the small pivot ball. The larger pivot cup can be removed by hand. The large pivot cup, small pivot cup, screws and the plate will be re-used.

Tool: Pliers

32. Apply the provided grease to the large factory pivot cup and snap it into place on the large ball portion of the Indy Shifter.

33. Apply the provided grease to the small factory pivot cup and snap it into place on the small ball portion of the Indy shifter stick.

34. Install the Indy shifter into the factory housing. The threaded hole on the large portion of the Indy shifter must be orientated to left side of the shifter housing looking forward.

35. Seat the large pivot cup aligning the two tabs to the two recessed slots in the bottom of the shifter housing.

36. Reinstall the shifter retaining plate. The plate should seat flat against the bottom of the shifter housing. Torque to the factory specifications.

Working in reverse order from step 29 to 24, reinstall the factory shift rod and assemble the shifter housing. Re-torque all bolts to factory torque specifications apply grease to all pivot points.

37. Install the new polyurethane bushing supplied with the kit.

38. Insert it into the bracket clip. You will need to form the clip bracket around the new bushing to make it easier for install. The holes need to be 4.21 inches apart to be re-installed. It will be improbable that you will get it to hold at 4.21 inches apart, but try to get it close to 4.21 inches as possible. You will rely on a pair of channel locks to compress the assembly during install.

39. Working in reverse order step 21 through step 11, reinstall the shifter housing assembly, driveline, crossmember and exhaust if undone. Re-torque all bolts to factory torque specifications.

40. Working from the inside of the vehicle slide the new reverse lockout down over the Indy shifter. This is a dry install no grease is required.

41. Align the reverse lockout block to the threaded hole on the larger portion of the Indy shifter. Use the retaining screw that was removed in step 9 to secure the reverse lockout into position.

Note: The retaining screw should tighten down to the Indy stick while allowing the reverse lockout to freely move up and down.

42. Reinstall the factory spring that was removed in step 8.

43. Compress the spring enough to install two of the provided set screws. Install the set screws evenly tightening them against each other.

44. Reinstall the O-ring and plastic ring that were removed in step 7.

45. Reinstall the rubber boot slide it down over the reverse lockout. Seat the bottom of the boot on the shifter housing. The upper portion of the boot will slide down into the machined groove on the reverse lockout.

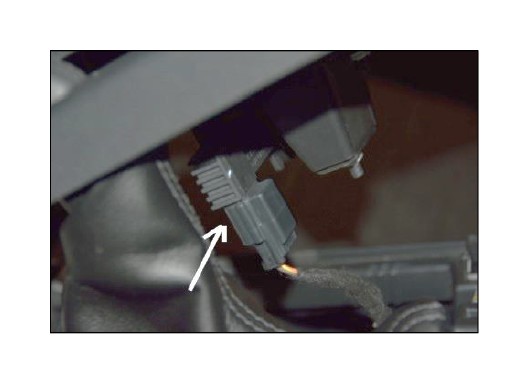

46. Reinstall the center console.

NOTE: Do not forget to re-connect the harness. The vehicle will not start if the harness is not reconnected.

47. Re-install the two (2) screws on both sides of the console.

Tool: 7mm Socket, Extension, Ratchet

48. Re-install the front driver side and passenger side panels from the center console.

49. Install the factory shift boot onto the reverse lockout. There are three threaded holes in the upper portion of the lockout align the notches on the shift boot to the holes on the reverse lockout and push the shift boot down into place.

50. Install the three supplied set screws and evenly tighten the shift boot into place.

51. Snap the chrome bezel back in place.

Shift Knob Installation

52. Apply ten full wraps of ½” wide Teflon thread tape on the threaded handle. Leave approximately 3/8” of exposed threads above the tape as shown in picture.

53. Apply the included LOCTITE® 271 thread lock compound to the threaded portion above the Teflon tape.

54. Screw knob onto handle until the bottom of the knob is just even with the top of the lockout collar (see photo). Continue to screw the knob an additional one turn plus whatever is necessary to align the shift pattern/logo properly.

Note: Screwing the knob on too far can prevent proper operation of the lockout collar and could cause damage to the knob.

55. Check for proper operation by engaging the reverse lockout and making sure the shifter will go into reverse.

IMPORTANT

Once this is confirmed, Avoid driving/shifting the vehicle for 1-2 hours. The LOCTITE® will set in approximately 10 minutes, but will not fully cure for 24 hours.

IMPORTANT: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE