Best Sellers

Redline Tuning Quicklift Mustang Hood Struts ('99-'04) - Installation Instructions

Installation Time

1 hours

Tools Required

- Power Drill

- 3/16" or Indexed #11 and 5/32" Drill Bits

- 5/16" Socket and Socket Wrench

- Fine Permanent Marker or Felt Tip Pen

- Masking Tape

- Tape Measure

- Hammer and Center Punch

- Rivet Gun, Capable of 3/16" Rivets (Most brands can handle this size)

Installation

1. Gather masking tape, tape measure, a permanent marker and also the two angled hood brackets (3-mounting holes).

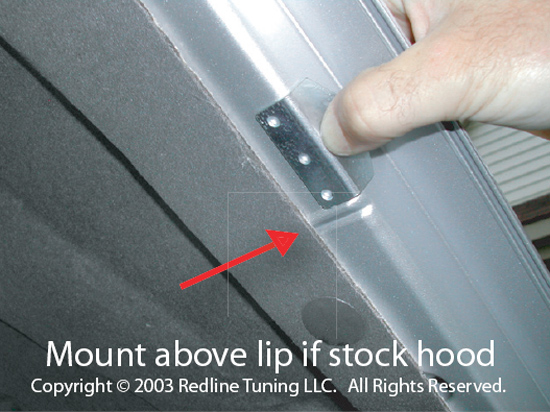

2. Place the bracket above the lip on the structural frame with the ball stud pointing outward or away from the vehicle. The base of the bracket should sit flat against the frame as shown. Leave a small amount of room between the bottom of the bracket and the lip (1/16") to keep the bracket from riding up onto the lip.

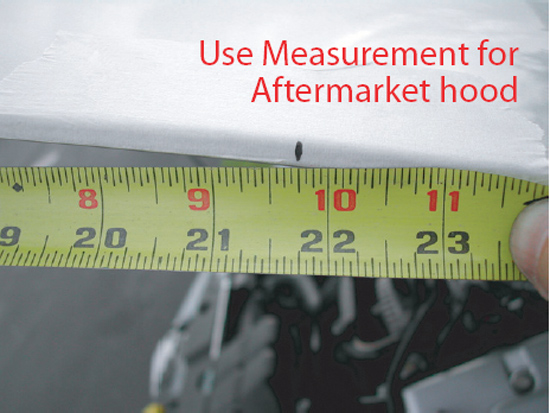

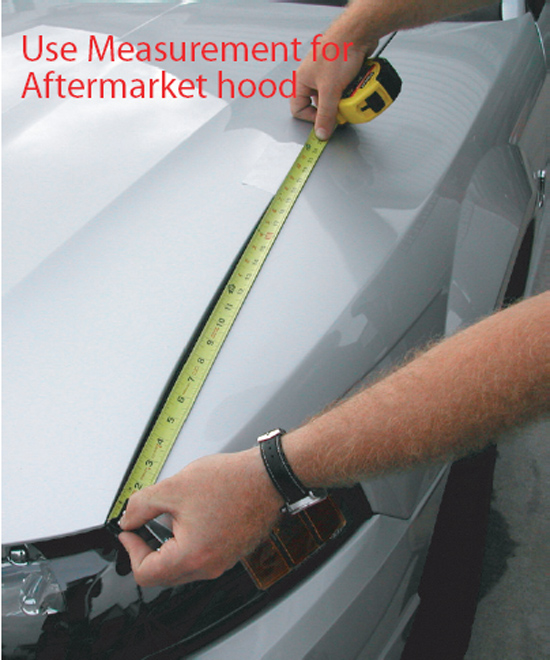

3. For aftermarket hoods without lip, measure from the front corner of the hood 21-3/4" and place mark on tape - use this line to place the bracket at the centerline of the ball stud.

4. Holding bracket in place, mark the center of the lower hole using a permanent felt tip marker. Be sure the bracket is straight and sitting flat against the hood's frame.

5. Set bracket aside. Using a center punch and a hammer, tap the center of the mark you just made (this indention will help guide the drill bit and keep it from wandering).

6. Place bracket back in place to be sure it is still centered where it should be.

7. Carefully drill the lower bracket hole as shown to the right using a (#11 indexed bit) or (use 3/16" bit if #11 bit is not available).

8. If you do not have a #11 indexed bit, you can use the 3/16" bit, however you may have to test fit the rivet and slightly ream hole until rivet fits tightly through bracket and hole - 3/16" is slightly smaller than the #11 bit. Do not use any other drill bit sizes!

9. Wrap a piece of electrical tape around the drill bit about 1/4" from the tip to prevent the bit from denting the hood skin. Use new and sharp bits!

10. Hold the bracket in position.

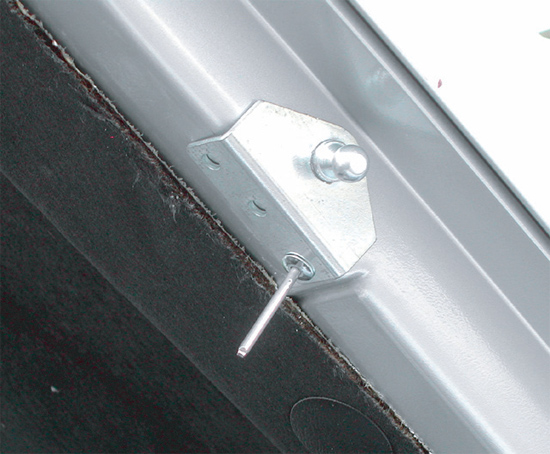

11.With the bracket lined up again, place the gold shafted rivet through the bracket and hole with the long stem sticking outward - shown to the right. The rivet may require a few twists while pushing it in.

12. Check to be sure your rivet gun has the 3/16" rivet head installed, then slide rivet gun onto rivet. While applying downward force on rivet and bracket, firmly squeeze riveter handle multiple times until rivet gun pops and snaps off the rivet stem.

13. Reposition or rotate bracket into the proper position against hood lip. Carefully drill the second hole through bracket hole and hood.

14. Wrap end of drill bit 1/4" down from tip with electrical tape to keep drill bit from pulling through and hitting hood skin.

15. Carefully drill the third center hole (a 3/16" drill bit is required for the this hole) - follow same precautions. Then rivet using the Aluminum rivet (longer rivet, 2 included). This rivet helps stabilize the bracket and should be installed last. We recommend installing this rivet when mounting to hoods made of fiberglass, composite materials, carbon fiber and other non-metal hoods. Since the stock hood is composite, install this rivet.

16. The Mustang hood has a symmetrical under structure. Repeat Steps 1-15 to install the upper passenger hood bracket. Take your time.

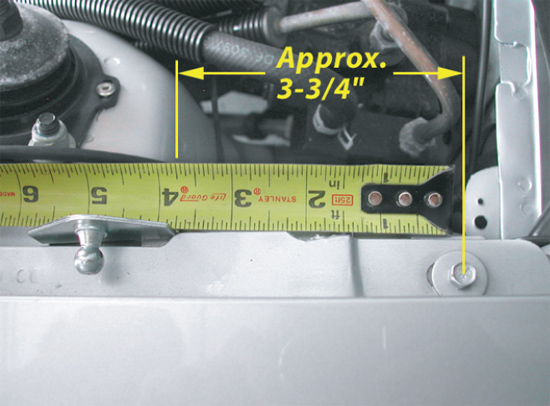

17. Hold the bracket in position as shown below. The bracket should sit 1" from the fender with the ball stud pointing outward or away from the vehicle and approximately 3-3/4" from upper fender bolt to the edge of the bracket.

18. The bracket will be touching the angled corner of the fender lip.

19. The bracket should span an area where two sections of steel are overlapping.

20. Mark upper hole using a fine permanent marker.

21. Using a center punch and a hammer, tap the center of the marked hole. This will help guide the drill bit and keep it from wandering during the following step.

22. Drill the upper or right hole at the marked position using a sharp 5/32" drill bit.

23. Using a color matching paint, touch up the area where you just drilled the hole.

24. Using a 5/16" socket and wrench, carefully screw the right or upper screw into the fender. Apply adequate pressure while screwing the sheet metal screw in - you will be creating threads through the layers of steel on the fender lip and it will require force.

25. Using a permanent marker, mark the left or lower hole of the fender bracket. Be sure the bracket is parallel to the fender.

26. Using a center punch and a hammer, tap the center of the marked hole. This will help guide the drill bit and keep it from wandering. Bracket is not shown in photo, but should be installed from the right hole of bracket while marking and punching.

27. Drill the second hole (hole closer to the front of the vehicle) at the marked position using a 5/32" drill bit. Do not ream or over drill the hole - any larger and the threads will not hold securely.

28. Attach the bracket using the same 5/16" socket and wrench. Secure both screws and bracket at this time.

29. Repeat Steps 16-28 to attach the passenger side fender bracket. The vehicle is symmetrical so the same locators can be used. Feel free to measure off of key areas to ensure a symmetrical installation.

30. CYCLE EACH GAS SPRING BEFORE INSTALLING - firmly hold a gas spring with both hands by the thick cylindrical end - firmly press down on the floor or carpet and compress the spring. Do this to both springs. Have a friend hold the hood up. Remove the stock prop rod assembly at this time.

31. Install the driver's side gas spring with the cylinder at the top (large end up). Be sure that the sockets snap securely onto the ball studs. Have friend remain holding the hood up until Step 16 is completed. This procedure is most easily done if the hood ends are snapped on first and attach the lower fender ball studs last. Photos may not represent the gas spring direction indicated here.

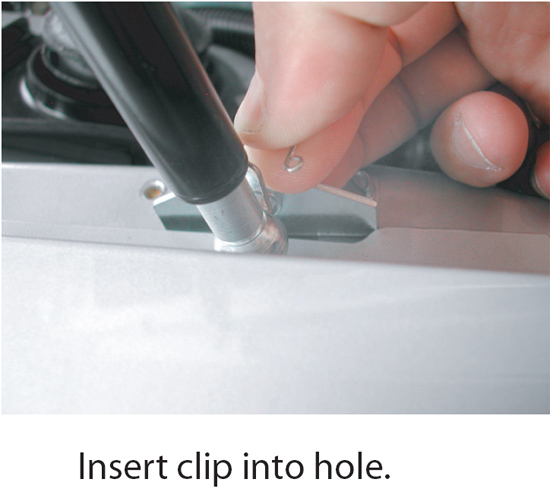

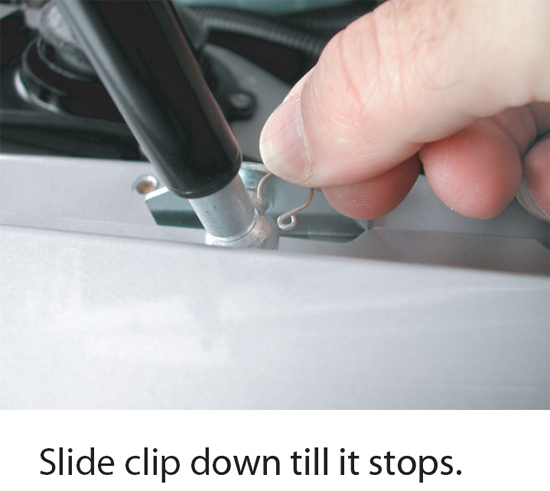

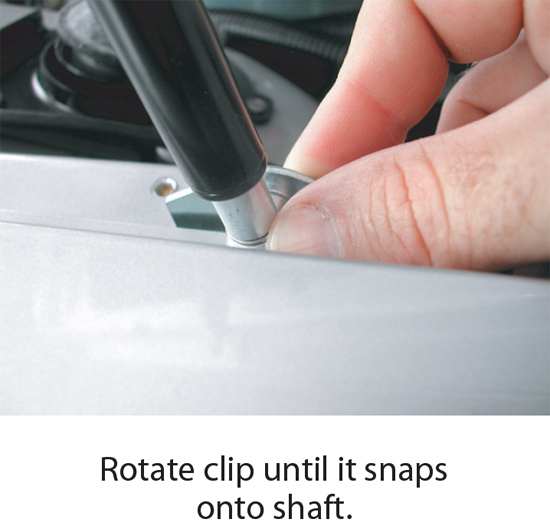

32. Insert the gas spring locking clips as shown below.

33. Note: Photos below show the fender end of the ball stud - you will find it easier if you first install the hood end of

the springs, including locking clips, and then move to the lower fender ends last.

Installation instructions provided by Redline Tuning