How to Install Air Lift Performance Suspension Kit - Rear (94-04 All; Excluding 99-04 Cobra) on your Ford Mustang

Shop Parts in this Guide

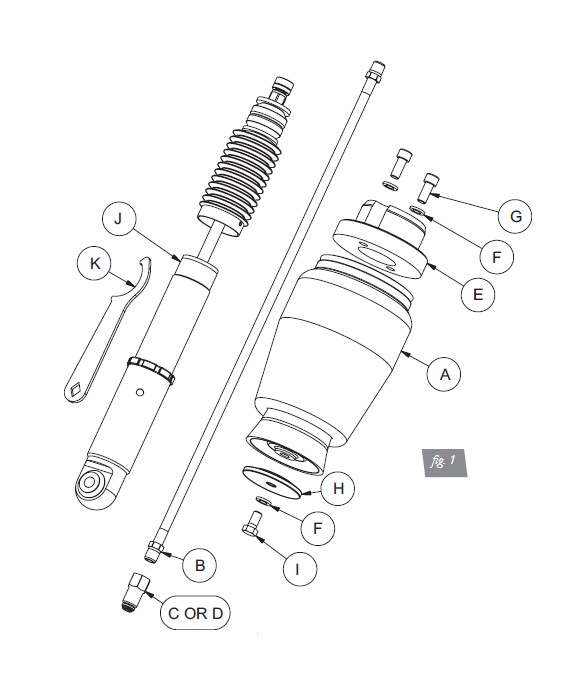

Installation Diagram

HARDWARE LIST

Installing the Air Suspension

PREPARING THE VEHICLE

1. Elevate and support the vehicle from approved lifting points.

2. Remove the rear wheels (fig. 2).

REMOVING THE STOCK SUSPENSION

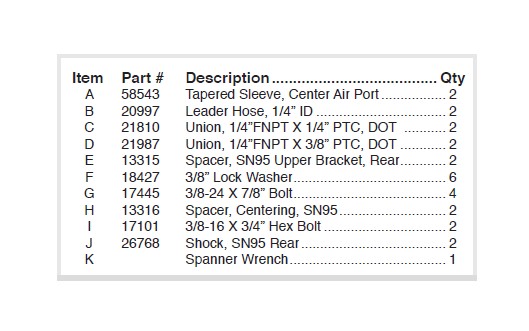

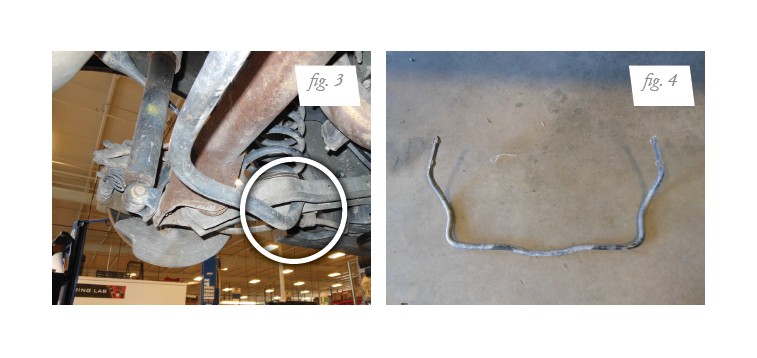

1. Unbolt the stabilizer bar from the lower control arms (figs. 3 and 4).

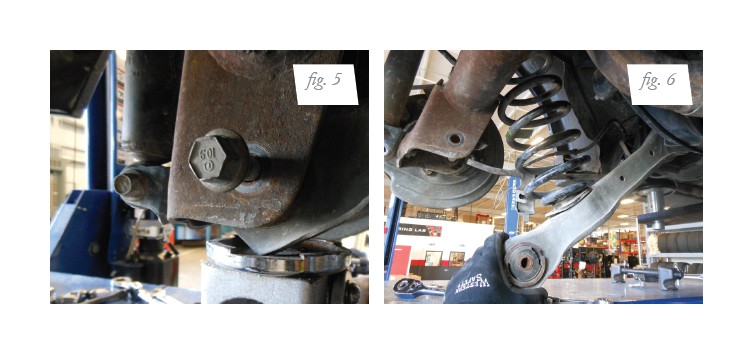

2. Support the lower control arm and remove the bolt attaching it to the axle. Lower the

control arm down and remove the coil spring. (figs. 5 and 6).

CAUTION: THE COIL SPRING IS UNDER PRESSURE, DO NOT UNBOLT THE CONTROL ARM WITHOUT SECURELY SUPPORTING THE ARM.

3. Reattach the lower control arm to the axle. Do not torque the bolt at this time (fig. 7).

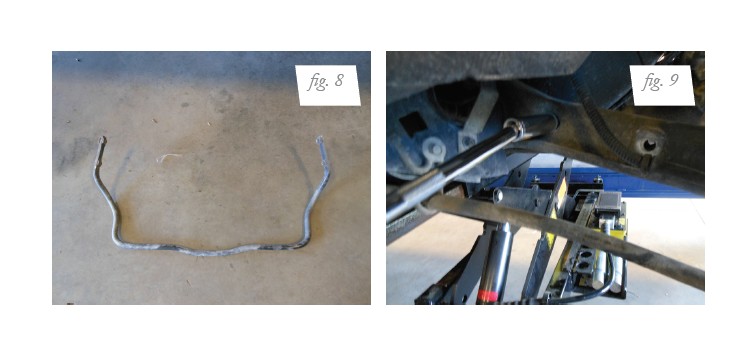

4. Reinstall the stabilizer bar (figs. 8 and 9). Torque bolts to 47 Nm (35 ft-lbs.).

5. Unbolt the lower shock mount (figs. 10 and 11).

6. Within the trunk, remove the carpet, unthread the rod nut and remove the shock from the vehicle (figs. 12 and 13).

AIR SUSPENSION INSTALLATION

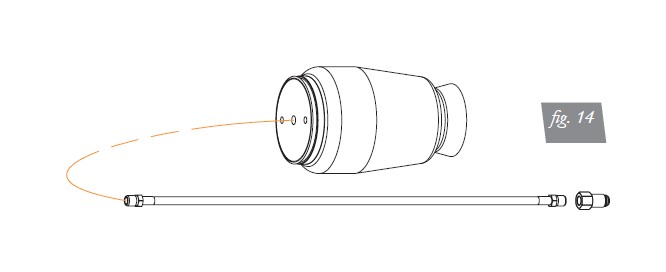

1. Install the leader hose into the air spring. Apply thread sealant to the threads of the

leader hose. Tighten the appropriate fitting to the air line (one and three-quarter turns

beyond hand-tight). Tighten the leader line into the air spring (one and three-quarter

turns beyond hand-tight) (fig. 14).

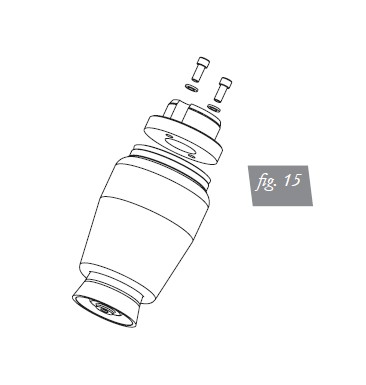

2. Attach the upper mount spacer to the air spring upper end cap with the supplied bolts

and lock washers (fig. 15). Torque bolts to 27 Nm (20 ft-lbs.).

3. Route the leader hose through the hole in the center of the upper spring perch and out

the windowed area facing the rear of the vehicle (fig. 16).

NOTE: Braided hose is not shown but routes in the same manner.

4. Insert the upper mount spacer into the upper coil spring seat (fig.17). Install the lower end cap over the lower coil spring seat (fig.18).

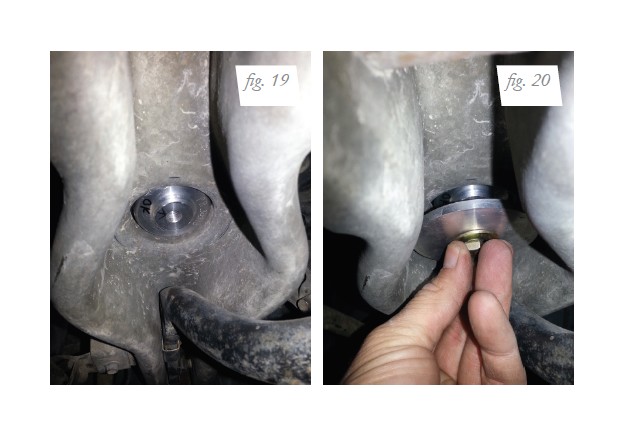

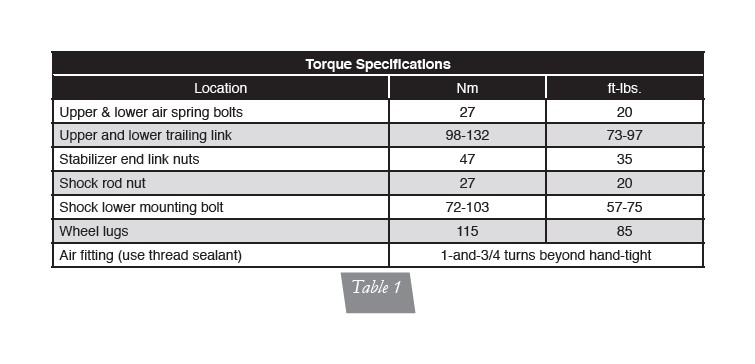

5. Reinstall the lower centering spacer with the supplied lock washer and bolt (figs. 19 and 20). Torque to 27 Nm (20 ft-lbs.).

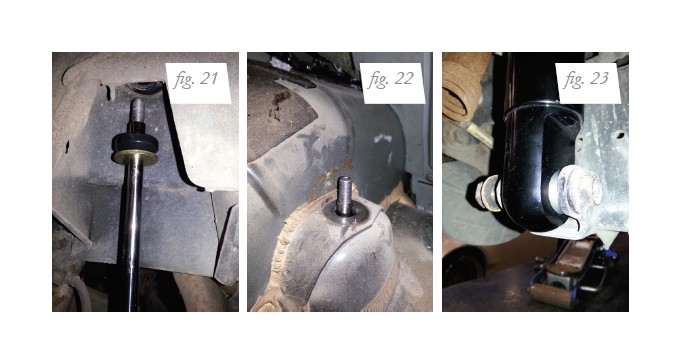

6. Remove the shock rod nut, upper washer and bushing from the new shock. Insert the shock into the shock tower, aligning the lower mount hole with the shock mounting bracket and insert the lower shock bolt through the mount (figs. 21-23). Do not torque at this time.

7. Apply the upper bushing, washer and shock rod nut (fig. 24). Torque the rod nut to 27 Nm (20 ft-lbs.) (fig. 25). Thread the damping adjuster onto the rod (fig. 26).

8. Fully compress the suspension using a jack. With the suspension compressed, review the best routing for the leader hose that is clear of all suspension components. Routing should also allow for the suspension to extend and compress without kinking or pulling the line tight or rubbing on other components. Check clearances to all other components.

9. With the suspension fully compressed, take a measurement from the fender to some

reference point – typically the center of the axle. Record this measurement as Max

Compression.

10. Cycle the suspension to Max Extension and record the measurement from the same

reference points.

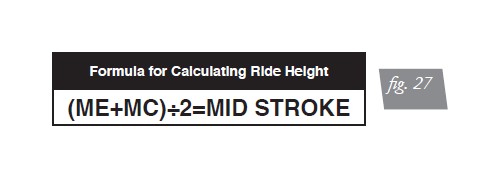

11. Add ME and MC then divide by 2. Set the suspension to this point. This position will give 50% stroke in either direction and is a starting point for ride height (fig. 27).

12. With the suspension at this position, loosen, then re-torque the upper and lower control arm bolts and lower shock bolts to manufacturer’s specifications (Table 1).

NOTE: Re-clocking the control arm bushings is critical to good ride quality, handling and bushing life. Do not skip this step!

DAMPING ADJUSTMENT

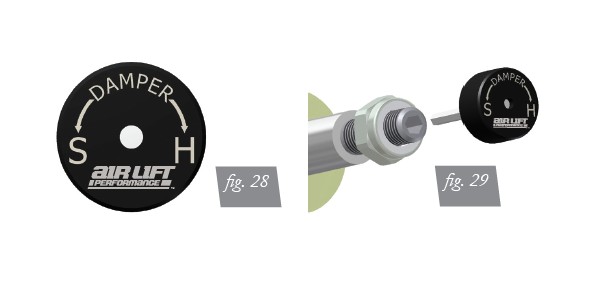

The dampers in this kit have 30 settings, or “clicks”, of adjustable compression and rebound damping characteristics. Damping is changed through the damper rod using the supplied adjuster (figs. 28 and 29) or a 3mm allen wrench.

Turn the adjuster clockwise and the damping settings are hardened. Turn the adjuster counterclockwise and the damping is softened.

Each strut is preset to “-25 clicks”. This means that the damper is adjusted 25 clicks away from full stiff. Counting down from full stiff is the preferred method of keeping track of, or setting, damping. This setting was developed on a 2002 Mustang GT and may need to be adjusted to different vehicles and driving characteristics.

ALIGNING THE VEHICLE

1. Using the control system, set the vehicle height to the new custom ride height.

2. If the custom ride height is lower than stock, we recommend loosening all pivot points (bolts, nuts) on any control arm, strut arm or radius rod that contains bushings. Once they have been loosened, re-torque to stock specifications.

NOTE: It may be necessary to cycle the suspension to loosen the bushing up from its mount. This will help re-orient the bushing at its new position and increase life of the bushings based on the custom ride height.

ADJUSTING EXTENDED OR DROP HEIGHT USING LOWER MOUNT

Your dampers have been pre-set at the factory to provide maximum drop height while

maintaining adequate tire clearance to the air spring. If you wish to gain more extended

height (lift), which is the same as reducing drop height, or want to lower the chassis further and there is still adjustment available at the lower mount, please use the following procedure:

1. Support the vehicle with jack stands or a hoist at approved lifting points.

2. Remove the wheel.

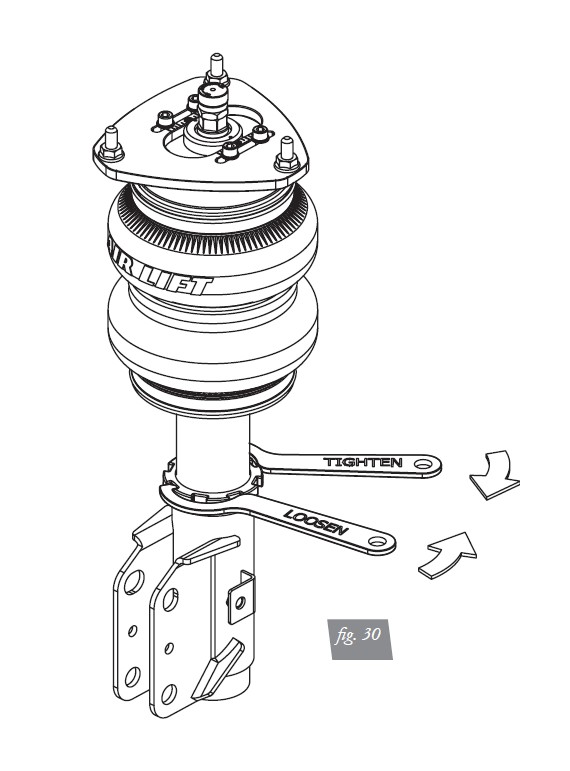

3. Using the supplied spanner wrench, loosen the lower locking collar (fig. 30).

4. Deflate the air spring to 0 PSI on the corner you are adjusting.

5. Disconnect lower mount from suspension.

6. Spin the lower mount to the desired location.

NOTE: Not all models will have further drop height available.

7. Re-install lower mount to suspension and torque fasteners.

8. Tighten the lower locking collar to the lower mount using significant force.

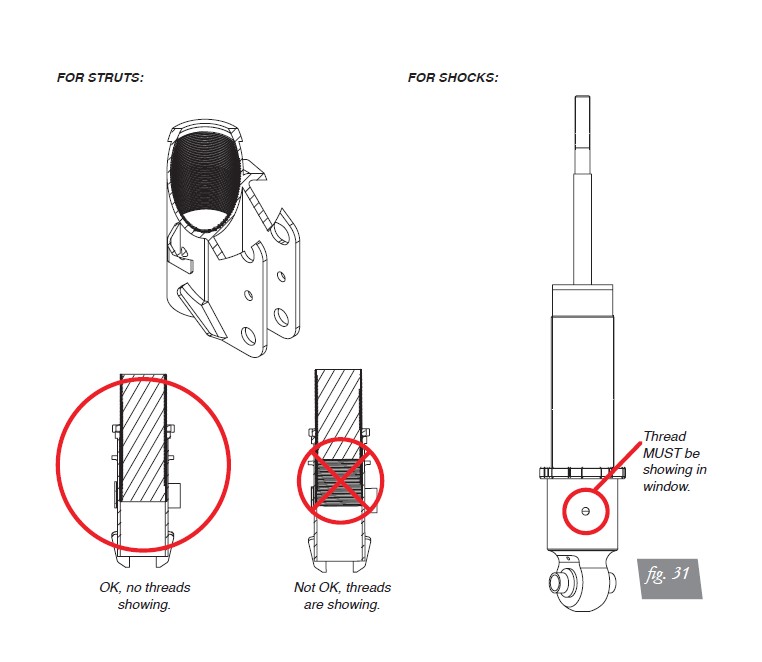

CAUTION: WHEN ADJUSTING HEIGHT UPWARDS, MAKE SURE THAT THE DAMPER BODY ENGAGES ALL THE THREADS OF THE LOWER MOUNT (FIG. 31). WHEN ADJUSTING DOWNWARDS, MAKE SURE THERE IS ADEQUATE AIR SPRING CLEARANCE TO THE TIRE/WHEEL ASSEMBLY. CLEARANCE MUST BE CHECKED WITH SYSTEM FULLY DEFLATED AS WELL AS FULLY INFLATED TO ENSURE THAT NO RUBBING OCCURS. FAILURE TO MAINTAIN ADEQUATE CLEARANCE CAN RESULT IN AIR SPRING FAILURE AND WILL NOT BE COVERED UNDER WARRANTY.

CAUTION: DO NOT ADJUST HEIGHT BY SPINNING AIR SPRING ON DAMPER! DOING SO MAY CAUSE AN AIR LEAK AND COMPROMISE THE ASSEMBLY.

Before Operating

CAUTION: MAKE SURE THE FRONT WHEELS ARE STRAIGHT WHEN DEFLATING AND REINFLATING AIR BAGS.

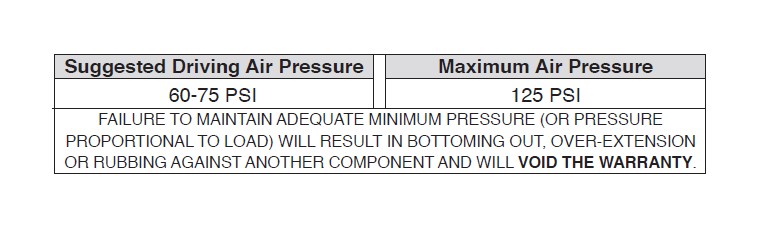

1. Inflate and deflate the system (do not exceed 125 PSI) to check for clearance or binding issues. With the air springs deflated, check clearances on everything so as not to pinch brake lines, vent tubes, etc. Clear lines if necessary.

2. Inflate the air springs to 75-90 PSI and check all connections for leaks.

3. Air Lift part #27669 or #27671, AutoPilot V2 Air Management System, is highly

recommended for this product.

4. Please familiarize yourself further with this product by reading the Product Use,

Maintenance and Servicing section.

INSTALLATION CHECKLIST

Clearance test — Inflate the air springs to 75-90 PSI and make sure there is at least 1/2” clearance from anything that might rub against each sleeve. Be sure to check the tire, brake drum, frame, shock absorbers and brake cables.

Leak test before road test — Inflate the air springs to 75-90 PSI and check all connections

for leaks. All leaks must be eliminated before the vehicle is road tested.

Heat test — Be sure there is sufficient clearance from heat sources, at least 6” for air

springs and air lines. If a heat shield was included in the kit, install it. If there is no heat

shield, but one is required, call Air Lift customer service at (800) 248-0892.

Fastener test — Recheck all bolts for proper torque.

Road test — The vehicle should be road tested after the preceding tests. Inflate the

springs to recommended driving pressures. Drive the vehicle 10 miles and recheck for

clearance, loose fasteners and air leaks.

Operating instructions — If professionally installed, the installer should review the

operating instructions with the owner. Be sure to provide the owner with all of the

paperwork that came with the kit.

POST-INSTALLATION CHECKLIST

Overnight leak down test — Recheck air pressure after the vehicle has been used for

24 hours. If the pressure has dropped more than 5 PSI, then there is a leak that must

be fixed. Either fix the leak yourself or return to the installer for service.

Air pressure requirements — Regardless of load, the air pressure should always be

adjusted to maintain adequate ride height at all times while driving.

Thirty day or 500 mile test — Recheck the air spring system after 30 days or 500 miles, whichever comes first. If any part shows signs of rubbing or abrasion, the source should be identified and moved, if possible. If it is not possible to relocate the cause of the abrasion, the air spring may need to be remounted. If professionally installed, the installer should be consulted. Check all fasteners for tightness.

Product Use, Maintenance and Servicing

MAINTENANCE GUIDELINES

NOTE: By following these steps, vehicle owners will obtain the longest life and best results from their air spring.

1. Check the air pressure before driving.

2. Never inflate beyond 125 PSI.

3. If you develop an air leak in the system, use a soapy water solution to check all air line connections, before deflating and removing the spring.

4. When increasing load, always adjust the air pressure to maintain normal ride height.

Increase or decrease pressure from the system as necessary to attain normal ride height for optimal ride and handling. Remember that loads carried behind the axle (including tongue loads) require more leveling force (pressure) than those carried directly over the axle.

CAUTION: FOR YOUR SAFETY AND TO PREVENT DAMAGE TO YOUR VEHICLE, DO NOT EXCEED MAXIMUM GROSS VEHICLE WEIGHT RATING (GVWR), AS INDICATED BY THE VEHICLE MANUFACTURER. ALTHOUGH YOUR AIR SPRINGS ARE RATED AT A MAXIMUM INFLATION PRESSURE OF 125 PSI, THE AIR PRESSURE ACTUALLY NEEDED IS DEPENDENT ON YOUR LOAD.

5. Always add air to the springs in small quantities, checking the pressure frequently. Sleeves require less air volume than a tire and inflate quickly.

6. Should it become necessary to raise the vehicle by the frame, make sure the control system is turned off before lifting.

Troubleshooting Guide

1. Leak test the air line connections, the threaded connection into the air spring, and all fittings in the control system.

2. Inspect the air lines to be sure none are pinched. Tie straps may be too tight. Loosen or replace the strap and replace leaking components.

3. Inspect the air line for holes and cracks. Replace as needed.

4. Look for a kink or fold in the air line. Reroute as needed.

If the preceding steps do not solve the problem, it is possibly caused by a failed air spring — either a factory defect or an operating problem. Please call Air Lift at (800) 248-0892 for assistance.

Tuning the Air Pressure

Pressure determination comes down to three things — level vehicle, ride comfort, and stability.

1. Level vehicle

If the vehicle’s headlights are shining into the trees or the vehicle is leaning to one side,

then it is not level. Raise the air pressure to correct either of these problems and level

the vehicle.

2. Ride comfort

If the vehicle has a rough or harsh ride it may be due to either too much pressure or not

enough. Try different pressures to determine the best ride comfort. See Air Lift suggested

driving air pressure.

3. Stability

Stability translates into safety and should be the priority, meaning the driver may need

to sacrifice a perfectly level and comfortable ride. Stability issues include roll control,

bounce, dive during braking and sponginess. Tuning out these problems usually requires

additional air pressure, strut damping, or both.

Checking for leaks

1. Inflate the air spring to 80 PSI.

2. Spray all connections and the inflation valves with a solution of 1/5 liquid dish soap and 4/5 water. Spot leaks easily by looking for bubbles in the soapy water.

3. After the test, deflate the springs to the minimum pressure required to restore the system to normal ride height.

4. Check the air pressure again after 24 hours. A 2-4 PSI loss after initial installation is

normal. Retest for leaks if the loss is more than 5 PSI.

Fixing Leaks

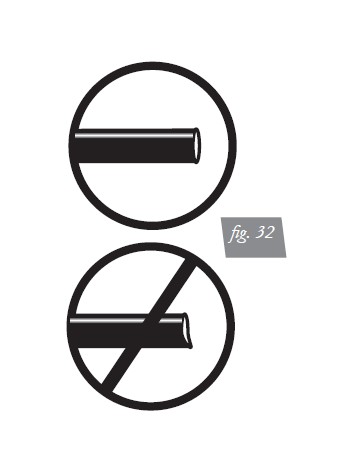

1. If there is a problem with a swivel fitting:

a. Check the air line connection by deflating the spring and removing the line by pulling the collar against the fitting and pulling firmly on the air line. Trim 1” off the end of the air line. Be sure the cut is clean and square (see fig. 32). Reinsert the air line into the push-to-connect fitting.

b. Check the threaded connection by tightening the swivel fitting another ½ turn. If it still leaks, deflate the air spring, remove the fitting, and re-coat the threads with thread sealant. Reinstall by hand tightening as much as possible and then use a wrench for an additional two turns.

2. If the preceding steps have not resolved the problem, call Air Lift customer service at (800) 248-0892.