How to Install a Cervinis Stalker Rear Spoiler on your 2010-2014 Mustang

Shop Parts in this Guide

Notice: Pre fit before painting! Install new, unpainted parts according

to these instructions! Then remove parts, paint them and re-install!

Painted or Altered Parts are Non-Refundable! After the parts have been

primed and painted install the double sided tape! The surface where the

3M double sided tape is contacting must be cleaned with isopropyl

alcohol and be a minimum of 75 degrees F constant throught the drying

process! Allow the 2-sided tape to dry 24 hours before driving!

Step 1. Pre-fitting the trunk and quarter extensions: If you have a factory trunk wing, it will need to be removed. Hold the trunk extension in place and check the alignment from the left to the right. Hold the quarter extensions in place and check the alignment with the quarter panel, rear bumper and trunk extension gap.

Step 2. Remove the trunk underside liner. Unplug and remove the third brake light.

Step 3

Install 1/4” 2-sided tape supplied in the hardware packet to the trunk third brake light cover panel useing the adhesion promoter packet.

(Apply adhesion promoter packet to cover panel before appling tape.)

as shown in Fig.A.

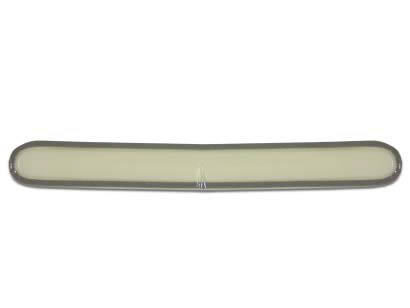

FIG. A

Step 4

Wipe trunk panel with rubbing alcohol around the third brake light opening in the trunk. Install the cover panel as shown in Fig.B (Access hole for wiring must be facing down.)

Step 5

Install the 1/2” 2-sided tape along along the top of the new third brake light 1/8” from the outer edge as shown in fig. C & fi g. D shows what side of the light is the top.

Fig. C

Fig. D

Step 5. Once the wing has been painted peel back about 2 inches of the tape backing on end of the third brake light. Fish the wires throught the predrilled 1/4” hole on the spoiler and set the third brake light in place. Remove backing and fi rmly

press light in place.

Step 6. Fish wire through the cover panel installed on trunk as shown in fig. E. Make wire connection to factory harness as follows; Black to Black & Yellow to Red. Use the wire connectors supplied in the hardware packet.

FIG. E

QTY DESCRIPTION HARDWARE #

1 1/2” ROLL OF 2-SIDED TAPE VHB 232

1 1/4” ROLL OF 2-SIDED TAPE VHB 51

2 2X2 SQUARE 2-SIDED TAPE VHB 2X2

2 BUTT CONNECTORS MC7227K13

1 LED THIRD BRAKELIGHT LG-17-80

Step 8. Installing the trunk wing: After the trunk extension has been painted, install the 1/2” 3m 2-sided tape along the guidelines 1/8” away from the outer edge of the part as shown in Fig A. Peel and fold about 2” of the red backing from the ends of each piece of tape. Place the trunk extension on the trunk so that the backing is exposed and can be pulled. (This will allow you to get the best alignment of the part.) Pull the backing slowly. After all the backing is removed, firmly press the edges of the extension to securely adhere the tape.

FIG. A

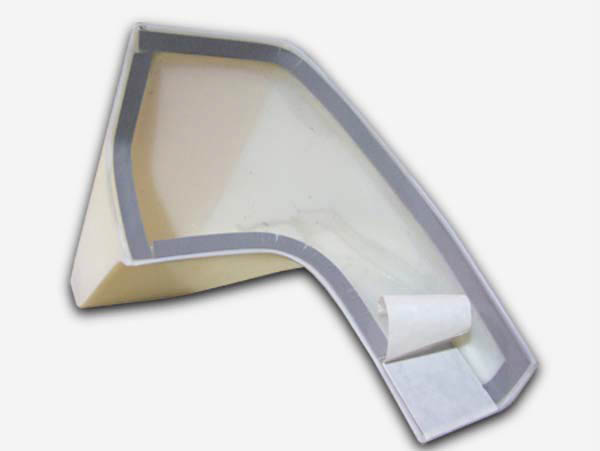

Step 9. Installing the quarter extensions: After the quarter extensions have been painted, install the 3M double sided tape along the guidelines 1/8” away from the outer edge of the part. Use the 2x2 block of double sided tape on the bottom of the quarter extension as shown in fi g B. Peel and fold about 2” of the red backing from each piece of tape, also fold the backing from each square of the tape. Then, place the trunk extension on the quarter panel so that the backing is exposed and can be pulled. (This will allow you to get the best alignment of the part.) Pull the backing slowly. After all the backing is removed, fi rmly press the edges of the extension to securely adhere the tape.

FIG. B

URETHANE PAINTING INSTRUCTIONS

VERY IMPORTANT: The following painting procedures MUST be followed EXACTLY for PROPER ADHESION and to prevent fish eyes.

1. To remove any mold release contaminants, clean the back of the part fi rst. Using 2 new clean rags, saturate the fi rst rag with plastic prep cleaner* and begin cleaning. Then use the second rag to remove the prep cleaner. Continuously fold both rags to their clean sides during the process. Use 3 sets of new rags throughout the process. This prevents mold release contaminants from transferring to the painted surface.

2. Repeat step one on the front of the part.

3. Rinse the part with water. Apply a generous amount of Ajax® or sand fi x* to a red scuff pad* (3M Scotch Brite Brand) and scrub the surface to be painted THOROUGHLY (especially where the 2-sided tape is installed, on the back side of the part, and all the hard to reach areas). Then rinse with water and dry. The scrubbed surface should be dull. If any shiny spots show, repeat the process on those areas.

4. Using another set of clean new rags, again clean the surface to be painted with plastic prep cleaner.

5. Spray the surface to be painted with adhesion promoter* including the areas where the 2-sided tape is installed (follow the instructions on the can for application and drying time).

6. Apply 3 to 4 coats of urethane primer* with fl ex additive* (follow the instructions on the can for application and drying time).

7. Wet sand primer with 600 grit sandpaper. Be careful not to sand through the primer. If you do, you MUST clean those areas with plastic prep cleaner, apply adhesion promoter and prime. Once the primer has dried, wet sand the areas that were touched up. Your surface is now ready for paint.

* These items can be purchased at any auto body supply store.

Note: Make sure you PRIME and PAINT the areas where the 2-sided tape is used as you would if it was the finished sided of the part. The tape adheres best when it is applyed to a painted surface.