How to Install a Metco Motorsports Crank Pulley Kit - 4lb Boost on your 2003-2004 Mustang Cobra

It is only necessary to raise the front of the vehicle for the installation of this kit, however a chassis lift is preferred. Ensure that the vehicle is stable on the lift or jack stands.

The negative battery terminal should be disconnected prior to starting work, and the vehicle should be left in 6th gear with the emergency brake tightly engaged. This is necessary to prevent engine movement when the original crank pulley bolt is loosened.

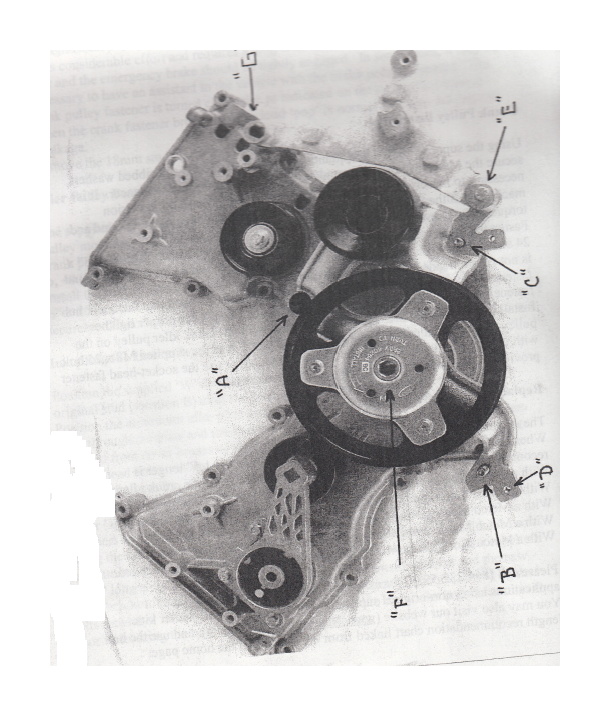

Removal of Original Pulley (Picture 1)

Remove the supercharger belt by depressing the factory tensioner arm with a Vi" drive ratchet or tensioner tool.

Remove the 13 mm nuts from the factory crank pulley cage (locations B & C in picture 1) and the 13mm bolt from location A.

Remove the 10mm bolt from the bottom of the alternator bracket (location E) and set aside. This fastener will be re-used. Also remove the 10mm bolt from the top of the alternator support bracket (location G) and pivot the alternator bracket to the side to clear the removal of the caged original crank pulley. This fastener (G) will also be re-used. In some instances, loosening the lower alternator mounting bolt provides additional clearance needed to complete re-assembly. Remove wiring harness bracket bolt (location D, beneath AC Compressor). This fastener is a 13mm nut and 13mm stud assembly and both must be removed and set aside for re-use. Also remove nut on wiring harness bracket at right side of crank pulley, and set bracket aside.

Remove the factory idler pulley from the original caged pulley bracket. The pulley will be re-used on the supplied billet idler relocation plate, but the original mounting bolt may be discarded.

Using the provided 14mm hex tool (Metco Motorsports PN MHT1400), loosen the original crank pulley retaining bolt (location F). Note: Loosening this fastener takes considerable effort and requires a long breaker bar. The car must be in 6th gear and the emergency brake should be tightly engaged. In sane eases, it may be necessary to have an assistant in the vehicle with me brake pedal depressed. "Ike crank pulley fastener is turned clockwise as ••*> aa il on the pulley far remoraL When the crank fastener breaks loose, a load pop* is normal and does not S"*-* breakage.

Remove the 18mm studs from locations B & C.

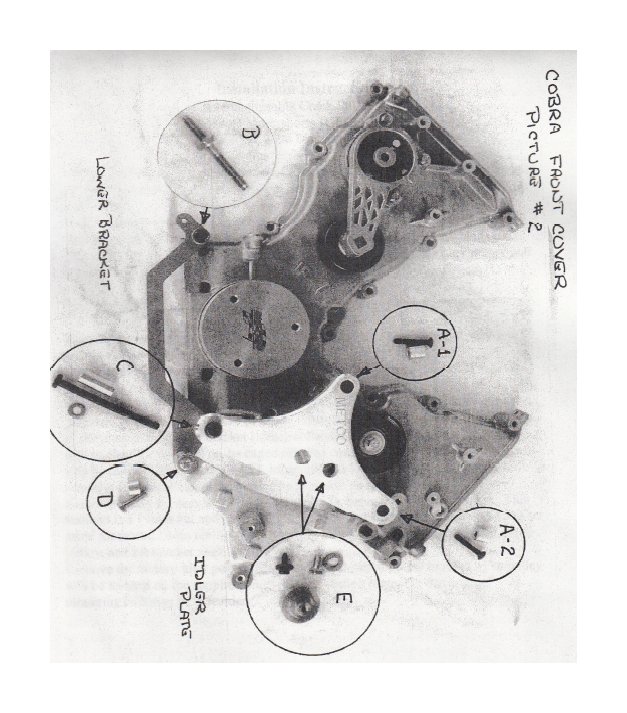

Idler Pulley Post & Plate Assembly (Picture 2)

The supplied billet idler mounting plate has two pulley post locations. The lower pulley mounting location should be used with stock diameter, 2 lb and 4 lb crank pulley rings, and the upper location should be used with larger diameter 6 lb, 8 lb and 10 lb crank pulley rings.

Install the Metco idler pulley post (E) in the appropriate location using the supplied Yir x 20 hex bolt and flat washer. Use blue thread locking compound and tighten securely. Do not mount the pulley on the pulley post at this time.

Installing the Lower Bracket & Idler Plate (Picture 2)

Position the supplied * W lower bracket as shown in Picture 2. Reinstall the original stud (location B) after the bracket but do not tighten at this time. Position the aluminum idler plate as shown in picture 2. Install 8mm flat head bolts through the plate and the aluminum spacers (approximately 0.780" long) into threaded front cover bosses as shown (locations A-l & A-2). Use anti-seize under the flat-head bolts (but not the bolt threads) to prevent galling and to facilitate later removal if necessary. Do not tighten these fasteners at this time. Install M8 x 120mm bolt with ribbed washer through idler plate and aluminum spacer (approximately 1.70" long) and into the front cover (location C). Fasteners at locations A-l, A-2, B & C can now be tightened securely. Swing the alternator support bracket into position and using the original bolts, bolt the bottom mount of the alternator bracket to the new lower bracket. The supplied 0.500" long aluminum spacer is used between the alternator bracket and the new lower bracket. Reinstall the original upper bolt (location G, Picture 2) and tighten bolts securely. In some instances, it may be helpful to install the bolt in location G prior to securing the bottom of the alternator bracket.

Reinstall the two wiring harness brackets at the left and right skies of the crank pulley using the original bolts. The right (driver's side) bracket may need a slight bend for adequate clearance.

Crank Pulley Installation

Using the supplied M10 x 25 (quantity 3) socket head bolts and ribbed washers, secure the Metco Motorsports crank pulley hub to the vehicle's balancer. It is necessary to loosely thread all bolts before tightening due to the precision machining of the three mounting holes. Use blue thread locking compound and torque all bolts evenly to 60 ft/lbs.

Fasten the crank pulley ring to the crank pulley hub using the supplied (6) 3/8" x 24 socket head bolts with ribbed washers. The use of a thread locking compound is not recommended if pulley rings will be changed at a later date. Tighten fasteners in a criss-cross pattern to 45 ft/lbs. It is recommended that the crank hub fasteners and pulley ring fasteners be checked periodically for proper tightness. Install the original (or Metco Motorsports replacement) crank idler pulley on the pulley post as installed on the idler relocation plate. Use the supplied M8 x 25 bolt with washer and use blue thread locking compound, or use the socket-head fastener provided with the Metco idler pulley. Tighten securely.

Replacement Belt Suggestions

The original belt is 8 ribs, 75.5" long.

When using a stock-diameter pulley ring, a belt that is 1.0-1.5" longer is recommended. This is necessary due to the repositioning of the crank idler pulley. With a Metco Motorsports 2 lb pulley ring, a 77" belt is recommended. With a Metco Motorsports 4 lb pulley ring, a 78" belt is recommended. With a Metco Motorsports 6 lb pulley ring, a 79" belt is recommended. With a Metco Motorsports 8 lb pulley ring, an 80" belt is recommended. With a Metco Motorsports 10 lb pulley ring, an 81.5" belt is recommended.

Please call (864/332-5929) for assistance with belt recommendations for applications using non-original supercharger pulleys or auxiliary idler kits. You may also visit our website (www.MetcoMotorsports.com'), and use the belt length recommendation chart linked from the left side of the home page.