How to Install a Professional Products Adapter For EFI Intake Manifold on Your 1994-1995 5.0L Mustan

Shop Parts in this Guide

Installation

This elbow adapter is used when installing a Professional Products 54020/54021 Intake Manifold system on a 1994 or 1995 Mustang. You will also need our EGR Supply Adapter#54152 and a Ford Racing strut tower brace #M-20201-A51 or Edelbrock strut tower brace #5225. Manifold will not clear stock strut tower brace.

INSTALLATION:

1. Remove the stock strut tower brace before installing manifold. Install manifold base per the instructions that come with the manifold.

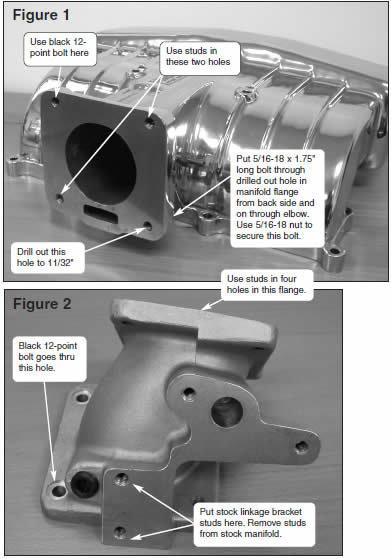

2. Before installing the upper plenum, drill out the threaded bolt hole shown in Figure #1 with an 11/32" drill. This will allow the installation of the supplied5/16" bolt from the back thru the Elbow Adapter. Note: If upper plenum is already installed, you can still drill out this hole but make sure that all chips are collected and not allowed to get into engine.

3. Install the upper plenum portion of the manifold assembly per the instructions supplied with manifold.

4. Remove the two throttle bracket studs from your stock manifold and install them into the two tapped holes on the Elbow Adapter. See Figure #2.

5. Install Elbow Adapter to upper plenum using supplied gasket and (2) supplied studs. Use the black 1-1/4 long 12-pointbolt in upper rear position as required for clearance. Put the 5/16-18 x 1.75" bolt through manifold flange from back side. Use nut on front of Elbow for this bolt. Use studs in other two holes. See Figure#1. Tighten bolts to 12-15 lb. ft.

6. Install the four supplied studs into the throttle body face of the Elbow Adapter.

7. Install throttle body onto Elbow Adapter using supplied gasket. Apply nuts, flat washers and lock washers on studs and tighten to 12-15 lb. ft.

8. Install EGR valve using supplied gasket onto Elbow Adapter. Install Professional Products #54152 EGR Supply Adapter.

9. Re-install all fittings, brackets and another parts removed during disassembly.

10. The original 11/32" vacuum hose must be extended using the supplied5.5" long hose and the supplied hose fitting.

11. Install aftermarket strut tower brace. Available from Ford Racing (#M-20201-A51) or Edelbrock (#5225).

Kit Contents:

(1) Elbow Adapter

(1) Throttle Body Gasket

(1) Adapter to Manifold Gasket

(1) EGR Gasket

(6) 5/16" x 1-1/2" T.B. Studs

(6) 5/16" Hex Nuts

(7) 5/16" Flat Washers

(7) 5/16" split lock washers

(1) 5/16" x 18 x 1-3/4" Hex Bolt

(1) 5/16" x 1-1/2" 12-pt Bolt

(1) 11/32" x 5.5" Long Hose

(1) 3/8" Hose Fitting

(1) 3/8" Pipe Plug (Installed)

(2) 1/8" Pipe Plugs

NOTE: All of the fasteners used in this installation are intended to be used with a flat washer, a lock washer, and a nut except the special black12-point bolt which does not use any washers or nuts.

Related Guides

-

Installation

-

Installation

-

Installation