Magnaflow Dual Exhaust Catback System Installation Guide (2005-2009 Mustang V6)

Shop Parts in this Guide

Installation

1. Disconnect the vehicle's battery before removal of the OEM exhaust. This will allow the computer to reset itself with the new system and prevent electrical accidents. Begin removal of the OEM system by loosening the band clamps that fasten the muffler and over-axle pipe to the catalytic converter. Unbolt the mounting brackets that mount the muffler to the frame, and remove the muffler assembly. Do not discard the OEM mounting brackets or fasteners as they will be reused to mount the new mufflers. You can now remove the over-axle pipe as well

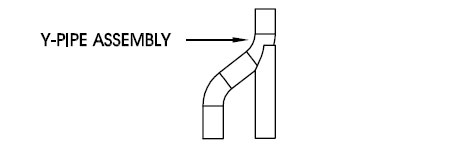

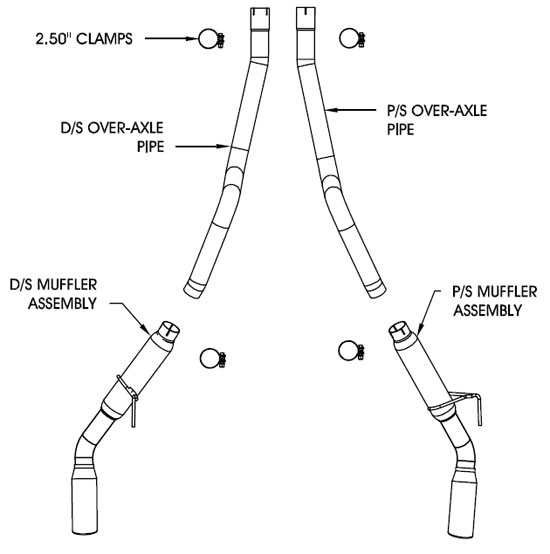

2. Install the OEM rear muffler bracket on the hanger of the new passenger-side muffler assembly, and install the OEM front muffler bracket on the driver-side muffler assembly. Fasten the Y-pipe assembly to the catalytic converter re-using the OEM clamp. Leave all clamps and fasteners loose for final adjustment of the complete system. Install the new over-axle pipes using the supplied 2.50" clamps. Install the muffler assemblies using the supplied clamps, and by bolting the mount brackets to the frame using the OEM fasteners. See Diagram 2 for more detail on mounting the passenger's side muffler. No drilling is required, the holes are already set up from the factory.

3. With all components mounted loosely, adjust the system for overall aesthetics and clearance of frame & bodywork. (MAGNAFLOW recommends at least 1/2" of clearance between the exhaust tips and the rear fascia to avoid heat related body damage or fire.)

4. Once a final position has been chosen for the new system, evenly tighten all fasteners from front to rear. The supplied band clamps must be VERY tight to properly align the pipes and prevent leaks (Approximately 65 ft-lbs). Inspect all hardware after25-50 miles of operation, and re-tighten if necessary.

Installation instructions provided by Magnaflow