How to Install Air Lift Performance 1000 Air Spring Kit (05-14 All) on your Ford Mustang

Installation Time

2 hours

Tools Required

- Hoist or Floor Jacks

- Safety Stands

- Safety Glasses

- Metric & Standard sockets/ratchet & wrenches

- Drill, Drill Bits

- Pliers

- Air Compressor or Compressed Air Source

- Spray Bottle with dish soap/water solution

Installing the Air Lift 1000 / Drag Bag SystemGETTING STARTED

1. Raise the rear of the vehicle. Put safety stands under the frame so the wheels can hang.

NOTE Although it is not necessary to remove the rear wheels, it may gain easier access to the rear coil springs for removal

2. Remove the bolts holding the rear brake line brackets to the frame on both sides (fig. 1). Pull the bracket from the frame so the lines are loose.

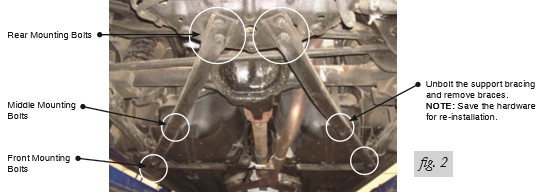

3. For all the models that have the body support bracing that runs underneath the differential, it will be necessary to remove these so that the axle can be dropped far enough to remove the coil springs. (fig. 2).

4. Disconnect the lower shock bolts and mark the coil spring/frame position so that they can be indexed correctly when reinstalling (fig. 3).

5. Drop the axle slowly and remove the coil springs.

6. Remove the upper spring seat isolator from the inside of the coil spring. Mark a line 1/4” from where the spring seats against the isolator and cut the post off (fig. 4).

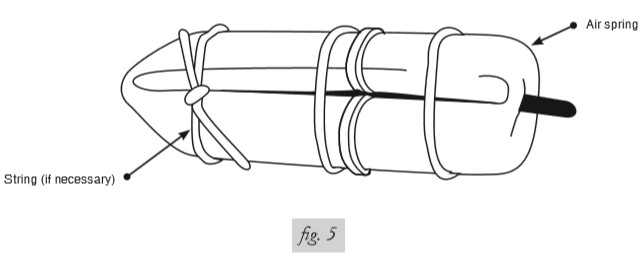

7. Remove the black cap and roll the cylinder up toward the stem end to exhaust as much air as possible. Install the black cap back onto the stem, unroll the cylinder and fold the cylinder into a hot dog bun shape (fig. 5).

8. Insert the cylinder through the bottom of the coil spring with the stem down and remove the black cap. Make sure the cylinder resumes it’s original shape.

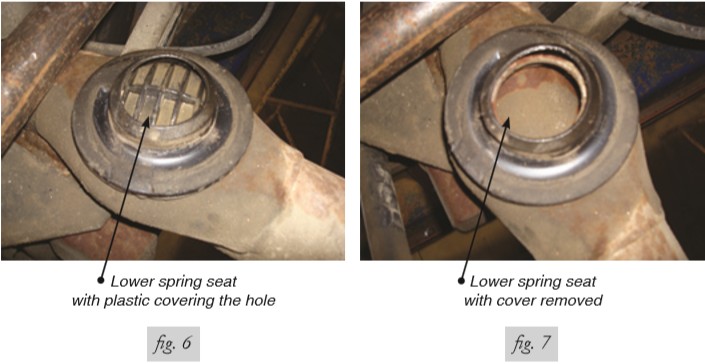

9. If the lower spring seat has a cover over the hole, remove the plastic cover so to gain clearance for the hose (fig. 6 & 7).

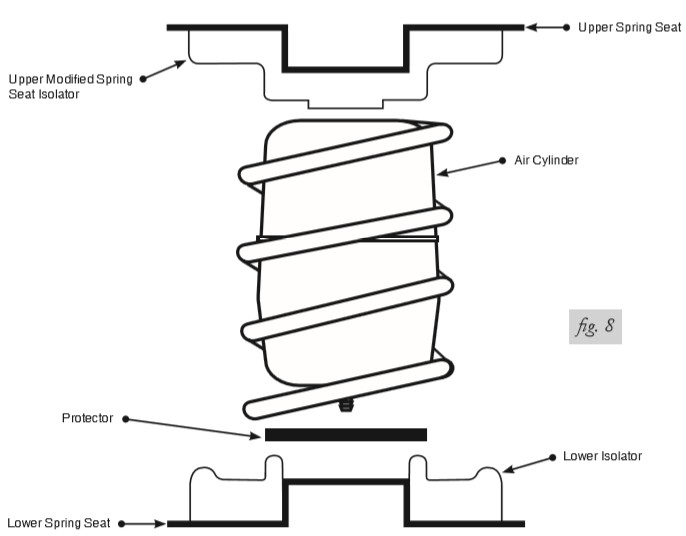

10. Set the isolator previously modified back onto the top of the spring and insert the spring, with cylinder installed, back onto the upper and lower spring mounts (fig. 8).

NOTE Be sure to index the spring back into the same position it was removed in by using the mark previously made in step four.

11. Install the protector at the bottom of the spring in between the cylinder and lower spring mount (fig. 8).

INSTALLING THE AIR LINE

A tee air line installation is recommended unless the weight in the vehicle varies from one side to the other and unequal pressures are needed to level the load or compensate for axle torque transfer in racing application. Dual air lines are used in this case.

TEE AIR LINE ROUTING

NOTE Not recommended for drag bag installations. Refer to dual air line routing section.

TO PREVENT THE AIR LINE FROM MELTING, MAINTAIN AT LEAST 8” FROM THE ExHAUST SYSTEM TO THE AIR LINE

1. Locate the desired tee location on the frame rail or cross member. Determine and cut adequate length of air line to reach from tee to the left and right side air springs.

LEAVE SUFFICIENT AIR LINE SLACK TO PREVENT ANY STRAIN ON THE FITTING DURING AxLE MOTIONS.

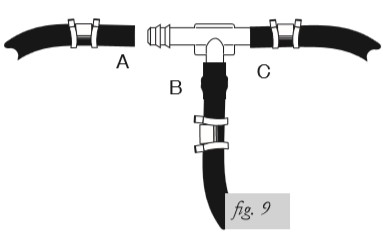

2. Slide an air line clamp onto the air line.

3. Push the air line over one side of the tee until all the barbs are covered. With a pair of pliers, slide the air line clamp forward until it fully covers the barbed section. Repeat entire procedure for other leg of the tee (fig. 9).

4. Route the air line along the cross member and either the lower control arm or the upper spring seat to the air spring.

5. Insert the air line through the spring seat and spacers.

Use this procedure for all air line connections:

a. Slide the air line clamp onto the air line.

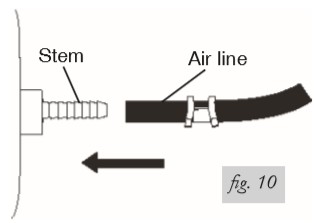

b. Push the air line over the barbed stem.

c. Compress the ears on the air line clamp with pliers and slide it forward to fully cover the barbed section.

6. Push the air line onto the stem, covering all the barbs (fig. 10). With the pliers, slide the air line clamp upward until it fully covers the barbed section.

7. Push the remaining air line over the last fitting on the tee and route it along the frame to the desired inflation valve location. Attach the air line with plastic straps or wire.

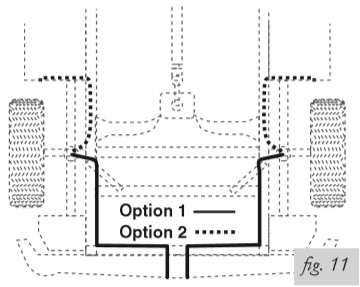

8. Select a location for the inflation valve in the gas cap well, the trunk, rear bumper, fender flange or behind license plate, insuring that the valve will be protected and accessible with an air hose (fig. 11).

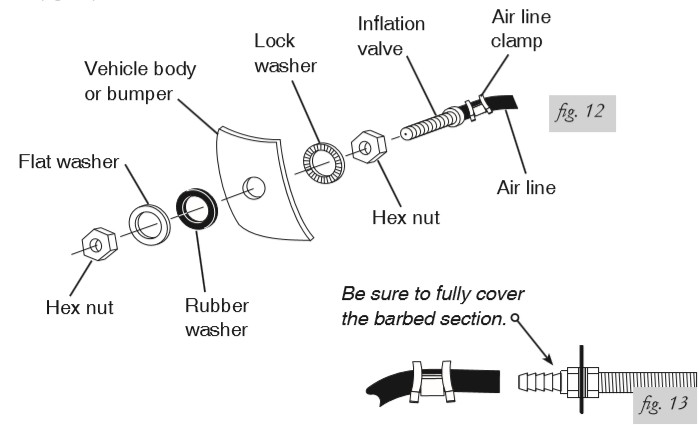

9. Drill a 5/16” hole for the inflation valve and mount as shown (fig. 12). The rubber washer serves as an outside weather seal.

10. Slide the air line clamp over the air line. Push the air line onto the fitting covering all barbs. Using pliers, slide the air line clamp forward until it fully covers the barbed section (fig. 13).

11. Raise the axle or lower the vehicle body until the air springs lightly touch the upper spring seat and lower spacers.

DO NOT INFLATE AIR SPRINGS BEFORE READING THE MAINTENANCE AND OPERATION SECTION.

13. Continue to “Completing the Installation.”

DUAL AIR LINE ROUTING

NOTE Recommended for Drag Bag installations. Also reference AD-300 for chassis setup information.

TO PREVENT AIR LINE FROM MELTING, KEEP IT AT LEAST 8” FROM ExHAUST SYSTEM.

1. Select a location for the inflation valves in the rocker panel flange, or rear bumper, assuring that each valve will be protected and accessible with an air hose.

2. Determine and cut adequate length of air line to reach from valve location to left side air spring.

LEAVE SUFFICIENT AIR LINE SLACK TO PREVENT ANY STRAIN ON FITTING DURING AxLE MOTIONS.

3. Insert the air line through the spring seat and spacer.

4. Slide air clamp onto the cut air line.

5. Push the air line onto the stem, covering all the barbed section (see fig. 10). With pliers slide the air line clamp forward until it fully covers barbed section.

6. Repeat process for right side.

7. Drill 5/16 “ hole for inflating valves and mount as illustrated. Rubber washer is for outside weather seal (see fig. 12).

8. Route air line along control arm and frame to inflation valve location and cut off excess.

9. Slide a clamp onto the air line and push the air line over the fitting, covering all the barbs. With pliers slide the air line clamp forward until if fully covers the barbed section (see fig. 13).

10. Raise axle or lower body until air springs lightly touch upper spring seat and lower spacers.

DO NOT INFLATE AIR SPRINGS BEFORE READING THE PRODUCT USE, MAINTENANCE AND SERVICING SECTION.

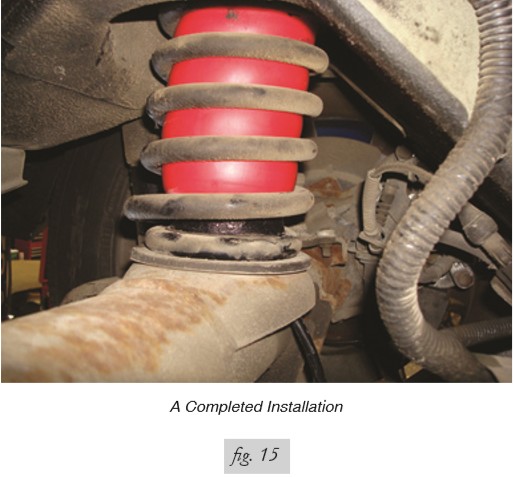

COMPLETING THE INSTALLATION

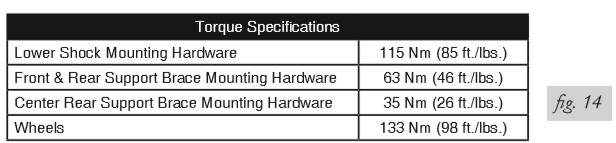

1. Once the hose has been installed, raise the suspension back up to ride height. Install the lower shock/bolts, wheels (if removed), braces (if equipped) that run underneath the differential and brake line brackets removed in first step. See torque table for torque specifications of bolts (fig. 14).

2. Inflate the air springs to 35 PSI. Test for air leaks by applying a liquid solution of 1/5 dish soap to 4/5 water in a spray bottle, to all valve cores, fittings and connections.

3. Lower vehicle to the ground. Read Maintenance Guidelines (page 11) for proper care of your air springs.

4. Set your pressure to desired height within the minimum and maximum pressure recommended in the Product Use, Maintenance and Servicing section (page 11).

NOTE For Drag Bag applications refer to AD-300 for additional chassis set-up information.

5. Recheck air pressure after 24 hours. A 2-4 PSI loss after initial installation is normal. If pressure has dropped more than 5 lbs retest for leaks.

Before Operating

INSTALLATION CHECKLIST

Clearance test — Inflate the air springs to 35 PSI and make sure there is at least ½” clearance from anything that might rub against each cylinder. Be sure to check the tire, brake drum, frame, shock absorbers and brake cables.

Leak test before road test — Inflate the air springs to 30 PSI and check all connections for leaks. All leaks must be eliminated before the vehicle is road tested.

Heat test — Be sure there is sufficient clearance from heat sources, at least 6” for air springs and air lines. If a heat shield was included in the kit, install it. If there is no heat shield, but one is required, call Air Lift customer service at (800) 248-0892.

Fastener test — Recheck all bolts for proper torque.

Road test — The vehicle should be road tested after the preceding tests. Inflate the springs to 25 PSI. Drive the vehicle 10 miles and recheck for clearance, loose fasteners and air leaks.

Operating instructions — If professionally installed, the installer should review the operating instructions with the owner. Be sure to provide the owner with all of the paperwork that came with the kit.

POST-INSTALLATION CHECKLIST

Overnight leak down test — Recheck air pressure after the vehicle has been used for 24 hours. If the pressure has dropped more than 5 PSI, then there is a leak that must be fixed. Either fix the leak yourself or return to the installer for service.

Air pressure requirements — I understand the air pressure requirements of my air spring system. Regardless of load, the air pressure should always be adjusted to maintain ride height at all times.

Thirty day or 500 mile test — I understand that I must recheck the air spring system after 30 days or 500 miles, whichever comes first. If any part shows signs of rubbing or abrasion, the source should be identified and moved, if possible. If it is not possible to relocate the cause of the abrasion, the air spring may need to be remounted. If professionally installed, the installer should be consulted. Check all fasteners for tightness.

Product Use, Maintenance and Servicing

MAINTENANCE GUIDELINES

NOTE By following these steps, vehicle owners will obtain the longest life and best results from their air spring.

1. Check the air pressure weekly.

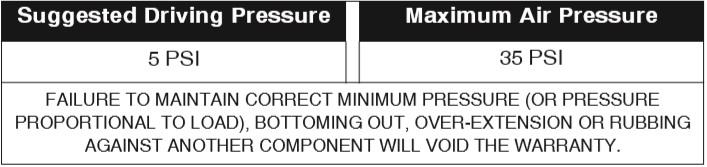

2. Always maintain normal ride height. Never inflate beyond 35 PSI.

3. If you develop an air leak in the system, use a soapy water solution to check all air line connections and the inflation valve core, before deflating and removing the spring.

4. When increasing load, always adjust the air pressure to maintain normal ride height. Increase or decrease pressure from the system as necessary to attain normal ride height for optimal ride and handling. Remember that loads carried behind the axle (including tongue loads) require more leveling force (pressure) than those carried directly over the axle.

FOR YOUR SAFETY AND TO PREVENT DAMAGE TO YOUR VEHICLE, DO NOT ExCEED MAxIMUM GROSS VEHICLE WEIGHT RATING (GVWR), AS INDICATED BY THE VEHICLE MANUFACTURER. ALTHOUGH YOUR AIR SPRINGS ARE RATED AT A MAxIMUM INFLATION PRESSURE OF 35 PSI, THE AIR PRESSURE ACTUALLY NEEDED IS DEPENDENT ON YOUR LOAD AND GVWR.

5. Always add air to the springs in small quantities, checking the pressure frequently. Cylinders require less air volume than a tire and inflate quickly.

6. Should it become necessary to raise the vehicle by the frame, make sure the system is at a minimum pressure (5 PSI) to reduce tension on the suspension/brake components. Use of on-board leveling systems do not require deflation or disconnection.

OPERATING TIPS

1. Inflate your air springs to 35 PSI before adding the payload. This will allow the air cylinder to properly mesh with the coil spring. After the vehicle is loaded, adjust your air pressure down to level the vehicle and for ride comfort.

2. When carrying a payload it will be helpful to increase the tire inflation pressure in proportion to any overload condition. We recommend a 2 PSI increase above normal for each 100 lbs additional load on the axle.

Troubleshooting Guide

1. Leak test the air line connections, the threaded connection into the air spring, and all fittings in the control system.

2. Inspect the air lines to be sure none are pinched. Tie straps may be too tight. Loosen or replace the strap and replace leaking components.

3. Inspect the air line for holes and cracks. Replace as needed.

4. Look for a kink or fold in the air line. Reroute as needed. If the preceding steps do not solve the problem, it is possibly caused by a failed air spring — either a factory defect or an operating problem. Please call Air Lift at (800) 248-0892 for assistance.

Tuning the Air Pressure

Pressure determination comes down to three things — level vehicle, ride comfort, and stability.

1. Level vehicle

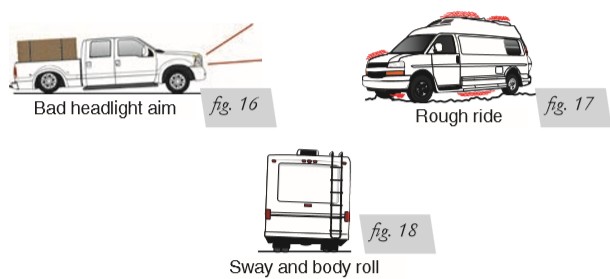

If the vehicle’s headlights are shining into the trees or the vehicle is leaning to one side, then it is not level (fi g. 16). Raise the air pressure to correct either of these problems and level the vehicle.

2. Ride comfort

If the vehicle has a rough or harsh ride it may be due to either too much pressure or not enough (fi g. 17). Try different pressures to determine the best ride comfort.

3. Stability

Stability translates into safety and should be the priority, meaning the driver may need to sacrifi ce a perfectly level and comfortable ride. Stability issues include roll control, bounce, dive during braking and sponginess (fi g. 18). Tuning out these problems usually requires an increase in pressure.

Guidelines for Adding Air

1. Start with the vehicle level or slightly above.

2. When in doubt, always add air.

3. For motorhomes, start with 50-100 PSI in the rear because it can be safely assumed that it is heavily loaded.

4. If the front of the vehicle dives while braking, increase the pressure in the front air bags, if equipped.

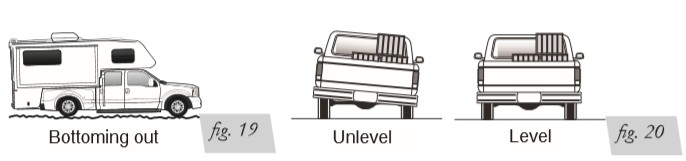

5. If it is ever suspected that the air bags have bottomed out, increase the pressure (fig. 19).

6. Adjust the pressure up and down to find the best ride.

7. If the vehicle rocks and rolls, adjust the air pressure to reduce movement.

8. It may be necessary to maintain different pressures on each side of the vehicle. Loads such as water, fuel, and appliances will cause the vehicle to be heavier on one side (fig. 20). As much as a 50 PSI difference is not uncommon