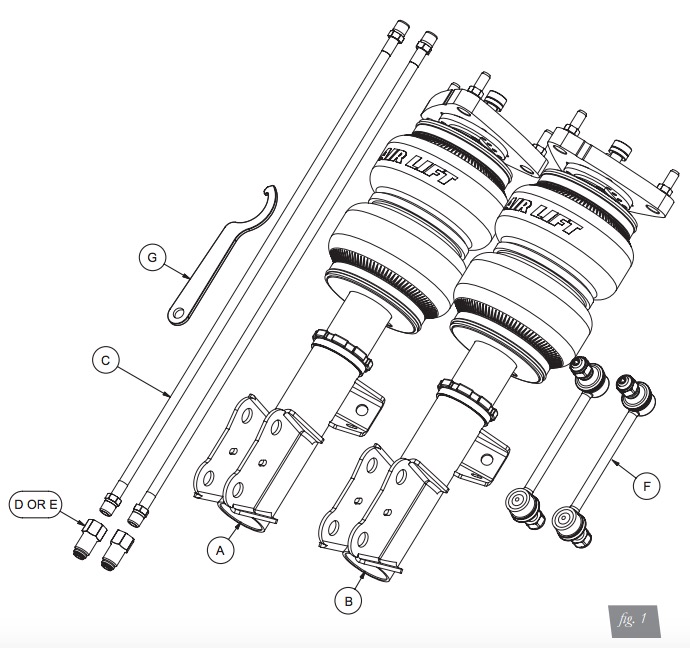

How to Install Air Lift Performance 3P Pressure Adjustable Air Suspension System on your Mustang

Step 1: Elevate and support the vehicle using its approved lifting points.

Step 2: Remove the front wheel and support the hub assembly (Fig. 2).

Step 3: Unclip the sensor wire from the two attaching points on the strut (Figs. 3 and 4).

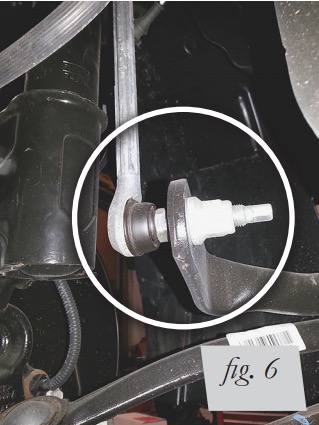

Step 4: Unthread the stabilizer bar end link nuts from the strut and bar. Remove the end link (Figs. 5-7).

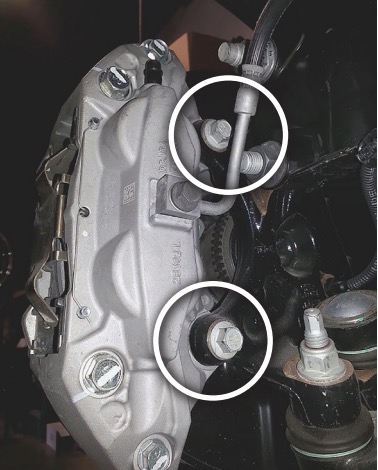

Step 5: Unbolt the brake caliper. Remove the brake caliper and brake rotor. Secure the brake caliper out of the way while preventing strain on the brake line (Figs. 8 and 9).

Step 6: Remove the two lower strut nuts and use a hammer to remove the bolts, while taking care not to damage the threads (Fig. 10). Support the knuckle to prevent damage to the lower ball joint.

Step 7: Within the engine compartment, unthread the three upper mount nuts and remove the strut from the vehicle (Fig. 11).

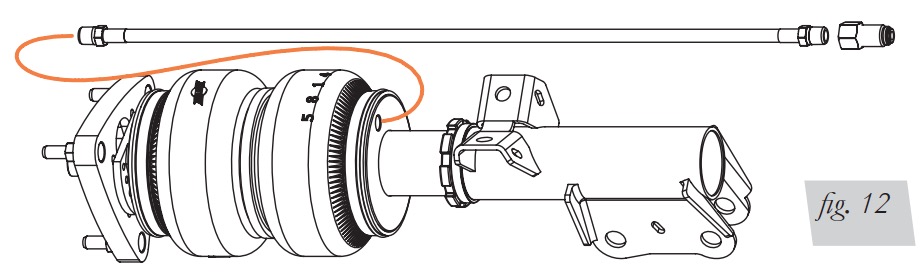

Step 8: Begin by installing the leader hose into the air spring. Apply thread sealant to the threads of the leader hose. Tighten the appropriate fitting to the air line (1 3/4 turns beyond handtight). Tighten the leader hose into the air spring 1 3/4 turns beyond hand-tight (Fig. 12).

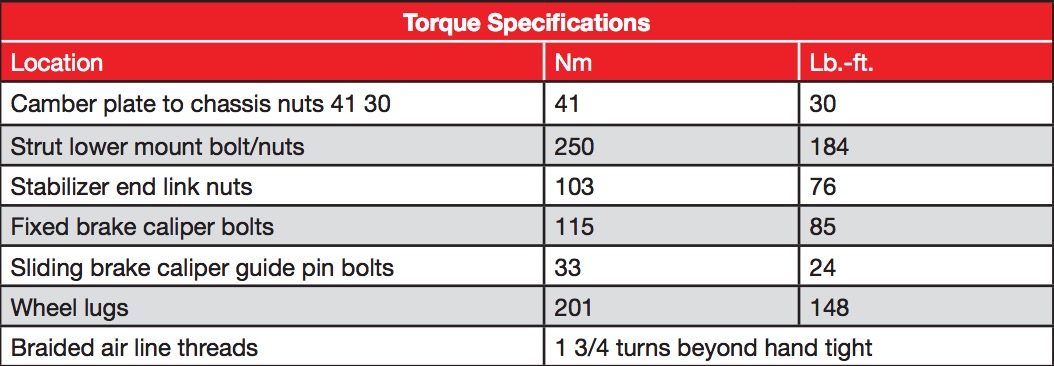

Step 9: Attach the camber plate to the strut tower and torque nuts to 41 Nm (30 lb.-ft.) (Fig. 13).

Step 10: Reinstall the lower mount bolts through the knuckle with the bolt heads toward the front of the vehicle (Figs. 14 and 15). A hammer may be required to push the bolts through the knuckle. Torque to 250 Nm (184 lb.-ft.).

Step 11: Reinstall the brake rotor and brake caliper. Torque fixed brake caliper bolts to 115 Nm (85 lb.-ft.). For sliding calipers (not shown), torque the guide pin bolts to 33 Nm (24 lb.-ft.) (Figs. 16 and 17).

Step 12: Install the new stabilizer end link. Torque nuts to 103 Nm (76 lb.-ft.) (Figs. 18 and 19).

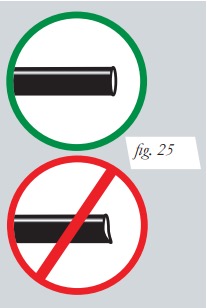

Step 13: Fully compress the suspension using a jack. With the suspension compressed, review the best routing for the leader hose that is clear of all suspension and steering components.

Step 14: Routing should allow for the suspension to extend and steer without kinking, pulling the line tight or rubbing on other components. Following the brake line routing is often a good place to start. Check clearances to all other components.

Step 15: With the suspension fully compressed, take a measurement from the fender to a chosen reference point – typically the center of the axle. Record this measurement as max compression (MC).

Step 16: Cycle the suspension to max extension (ME) and record the measurement from the fender to the same reference point.

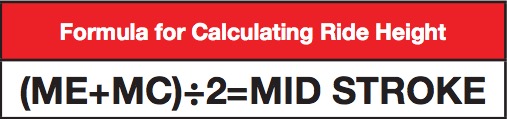

Step 17: Add ME and MC, then divide the total by 2. Set the suspension to this point. This position will give 50% stroke in either direction and is a starting point for ride height (fig. 20).

Step 18: With the suspension at this position, loosen, then re-torque all suspension bushing pivot joint fasteners to the manufacturer’s specifications.

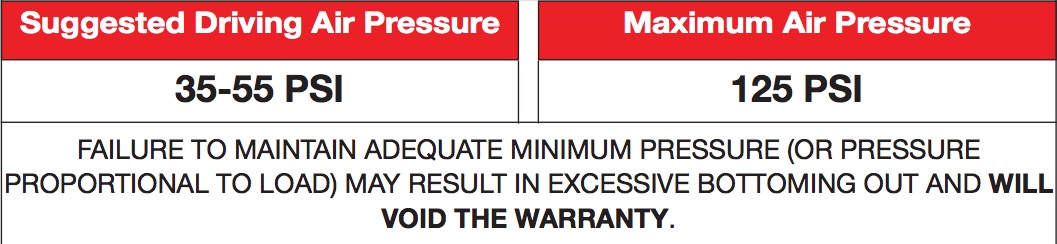

Step 19: . Inflate and deflate the system (do not exceed 125 PSI) to check for clearance or binding issues. With the air springs deflated, check clearances on everything so as not to pinch brake lines, vent tubes, etc. Clear lines if necessary.

Step 20: . Inflate the air springs to 75-90 PSI and check all connections for leaks.

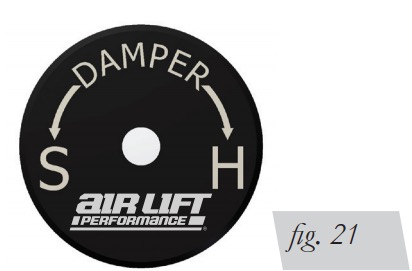

Step 21: The dampers in this kit have 30 settings, or “clicks,” of adjustable compression and rebound damping characteristics. Damping is changed through the damper rod using the supplied adjuster (Figs. 21 & 22) or an 3mm hex key (not included).

Step 22: . Turn the adjuster clockwise (H) and the damping settings are hardened, reducing oscillations and body motion. Turn the adjuster counterclockwise (S) and the damping is softened.

Step 23: Each damper in this kit is preset to “-17 clicks.” This means that the damper is adjusted 17 clicks away from full stiff, which starts at 0. Counting up from full stiff is the preferred method of keeping track of, or setting, damping. This setting was developed on a 2015 Ford Mustang 2.3L EcoBoost.

Step 24: Set the vehicle to the height at which it will most often be driven.

Step 25: If the ride height is lower than stock, Air Lift recommends loosening all pivot points (bolts, nuts) on any control arm, strut arm or radius rod that contains bushings. Once they have been loosened, re-torque to stock specifications (Table 1).

Step 26: Get a shop alignment of the vehicle at the new chosen ride height.

Step 27: Support the vehicle with jack stands or a hoist at approved lifting points.

Step 28: Remove the wheel.

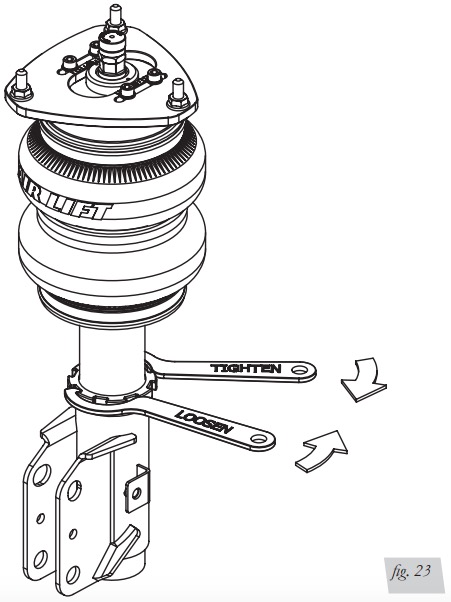

Step 29: Using the supplied spanner wrench, loosen the locking collar (Fig. 23).

Step 30: Deflate the air spring to 0 PSI on the corner you are adjusting.

Step 31: Disconnect lower mount from suspension.

Step 32: Spin the lower mount to the desired location

Step 33: Re-install lower mount to suspension and torque fasteners.

Step 34: Tighten the lower locking collar to the lower mount using significant force.