How to Install Borla 1-3/4 in. Long Tube Off-Road Headers (15-17 GT) on your Ford Mustang

Installation Time

1 days

Tools Required

- 3/8” Drive Ratchet

- 3/8” Drive Extension 3”

- 6mm Socket

- 10mm Socket

- 13mm Socket

- 7/8” Combination Wrench

- Spray Lubricant

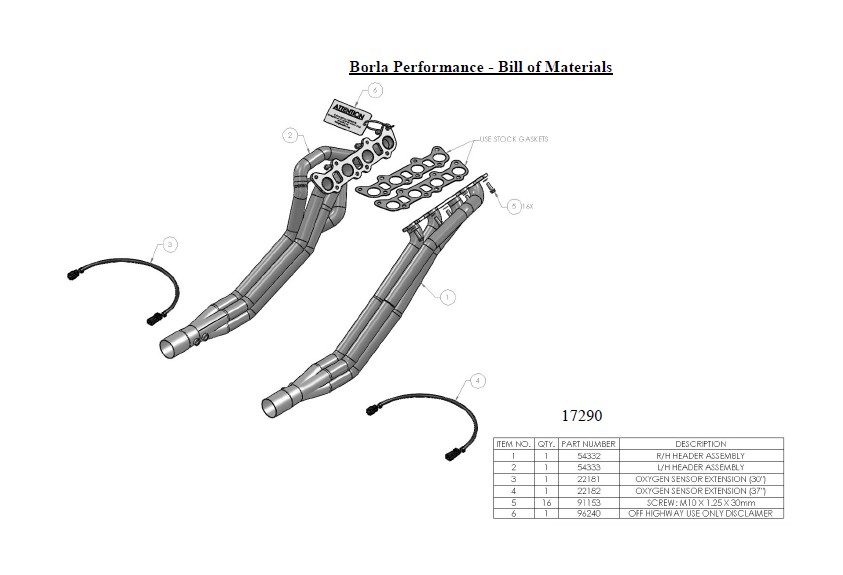

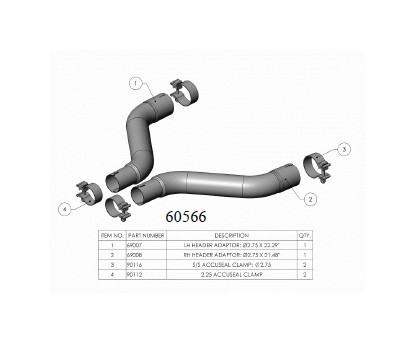

Borla Performance - Bill of Materials

Caution!!! Never work on a hot exhaust system. Serious injury in the form of burns can result If the vehicle has been in use and the exhaust system is hot, allow vehicle to cool for at least 1 hour. Always wear eye protection when working under any vehicle.

Note: It is our recommendation that you use a hoist or hydraulic lift to facilitate the installation of your new Borla Performance Exhaust System.

Taking all under car safety precautions, lift the vehicle using a hoist or hydraulic lift. Once this has been done, you may begin the removal of your old exhaust system from your vehicle.

Note: Before removing the original exhaust system from your vehicle, please compare the parts you have received with the bill of materials provided on the previous page to assure that you have all the parts necessary for the installation of your new Borla Performance Exhaust System.

Original Header System Removal

1. Disconnect negative lead from battery terminal prior to installa-tion. (See Fig.1)

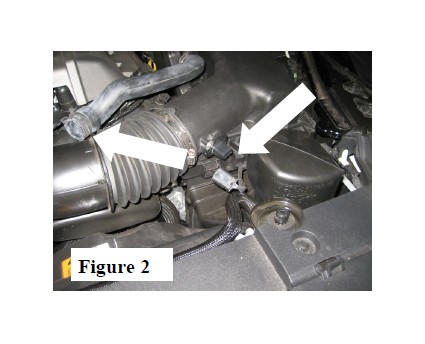

2. Remove the air box assembly and intake tube by disconnecting the sensor wiring, acoustic tube, and mounting bolt (10mm head). (See Fig. 2)

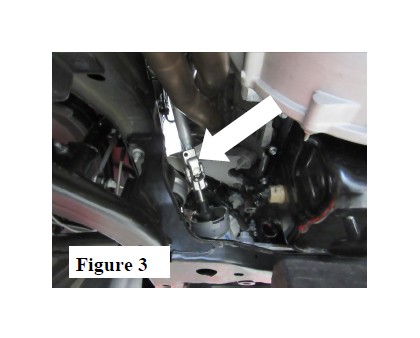

3. Unbolt the fastener (13mm head) retaining the steering shaft to the universal joint and separate the joint. (See Fig. 3)

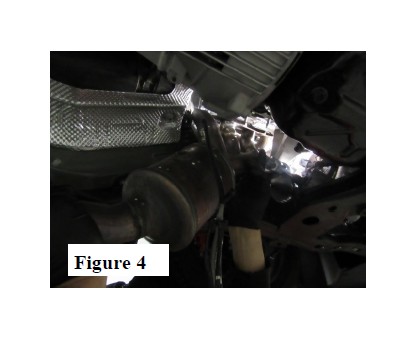

4. Loosen and remove the eight nuts (13mm head) securing the drivers side manifold to the engine. Disconnect two oxygen sen-sor harness connections and remove the drivers side manifold. (See Fig. 4)

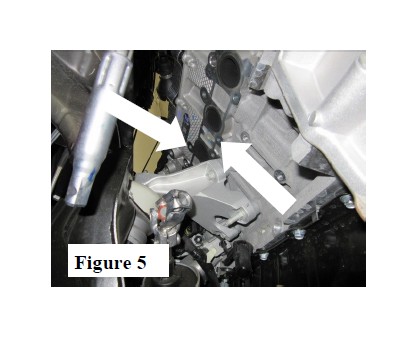

5. Remove all eight mounting studs from the engine using a 5mm socket or appropriate size star socket. Clean threads using a M10 x 1.25 tap. (See Fig. 5)

Warning: Use extreme caution during installation. Torque all fasteners ac-cording to manufacturer’s torque values and tightening sequence. DO NOT use air impact tools to tighten fasteners on Borla Performance Exhaust Sys-tems. Use of such tools may result in bent flanges or gasket contact areas leading to exhaust leaks.

Original Header System Removal

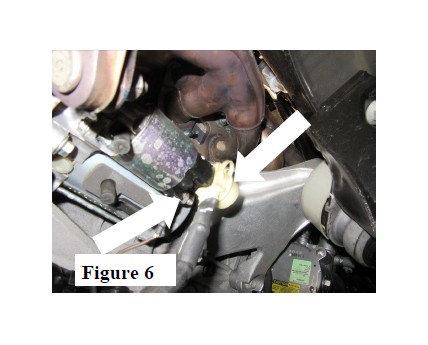

6. Disconnect wiring to the starter and remove the starter by removing three (10mm head) bolts. (See Fig. 6)

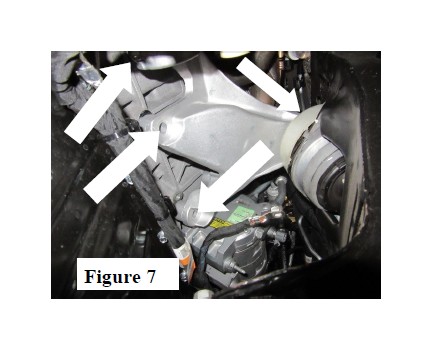

7. Support engine in a manner that will not damage the oil pan as the en-gine must be lifted slightly to remove the passenger side engine mount bracket. Once supported, remove four bolts (13mm head) securing the passenger side engine mount bracket to the engine and rubber isolator. (See Fig. 7)

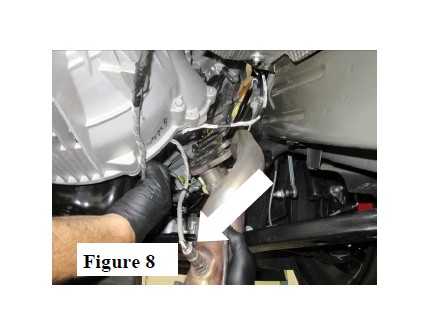

8. Remove eight nuts (13mm head) securing the passenger side manifold to the engine. Unthread the upstream oxygen sensor from the manifold and disconnect the downstream sensor from the wire harness. Remove passenger side manifold from the vehicle. (See Fig. 8)

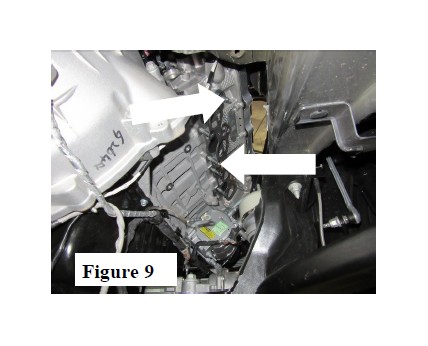

9. Remove all eight mounting studs from the engine using a 5mm socket or appropriate size star socket. Clean threads using a M10 x 1.25 tap. (See Fig. 9)

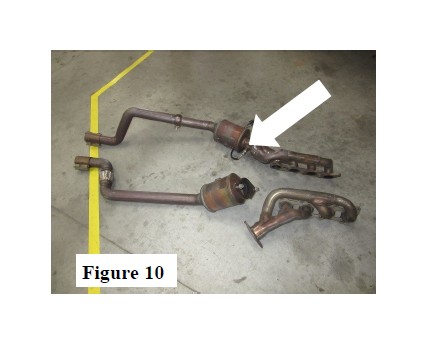

10. Remove all remaining oxygen sensors. Note the positions of the sensors so they can be reinstalled in there original positions. (See Fig. 10)

Warning: Use extreme caution during installation. Torque all fasteners ac-cording to manufacturer’s torque values and tightening sequence. DO NOT use air impact tools to tighten fasteners on Borla Performance Exhaust Sys-tems. Use of such tools may result in bent flanges or gasket contact areas leading to exhaust leaks.

Caution!!! Never work on a hot exhaust system. Serious injury in the form of burns can result If the vehicle has been in use and the exhaust system is hot, allow vehicle to cool for at least 1 hour. Always wear eye protection when working under any vehicle.

Note: It is our recommendation that you use a hoist or hydraulic lift to facilitate the installation of your new Borla Performance Exhaust System.

Taking all under car safety precautions, lift the vehicle using a hoist or hydraulic lift. Once this has been done, you may begin the removal of your old exhaust system from your vehicle.

Note: Before removing the original exhaust system from your vehicle, please compare the parts you have received with the bill of materials provided on the previous page to assure that you have all the parts necessary for the installation of your new Borla Performance Exhaust System.

Header System Installation

11. Inspect headers for signs of damage during transit. (See Fig. 11)

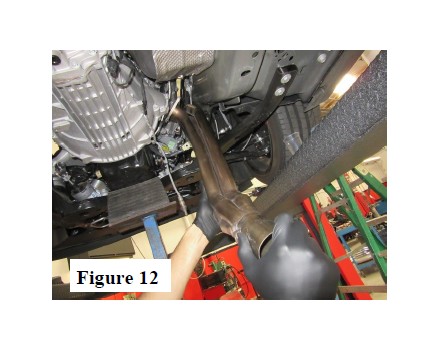

12. Position passenger side header in place and start all eight bolts. Tight-enheader bolts down to 18ft.lbs. Then tighten them all to 26ft.lbs. (See Fig. 12)

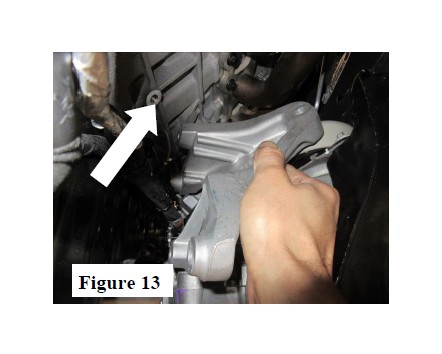

13. Place engine mount bracket back into position and replace fasteners. Tighten all four fasteners to 41ft.lbs (See Fig. 13)

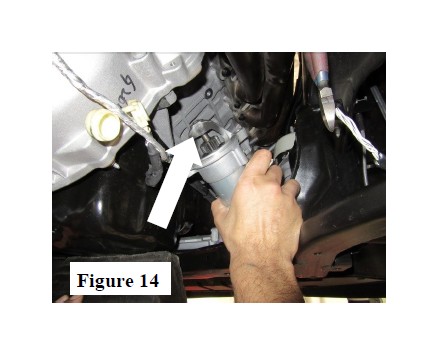

14. Install starter and replace fasteners. Tighten all three fasteners to 17ft.lbs (See Fig. 14)

15. Position driver side header in place and start all eight bolts.

16. Preliminary tighten header bolts to 18ft.lbs., then apply final torque to 26ft.lbs. (See Fig. 15)

Caution!!! Never work on a hot exhaust system. Serious injury in the form of burns can result If the vehicle has been in use and the exhaust system is hot, allow vehicle to cool for at least 1 hour. Always wear eye protection when working under any vehicle.

Note: It is our recommendation that you use a hoist or hydraulic lift to facilitate the installation of your new Borla Performance Exhaust System.

Taking all under car safety precautions, lift the vehicle using a hoist or hydraulic lift. Once this has been done, you may begin the removal of your old exhaust system from your vehicle.

Note: Before removing the original exhaust system from your vehicle, please compare the parts you have received with the bill of materials provided on the previous page to assure that you have all the parts necessary for the installation of your new Borla Performance Exhaust System.

Header System Installation

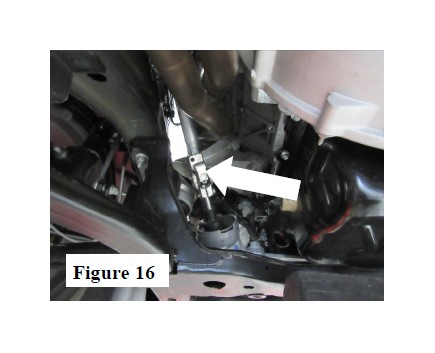

17. Replace steering shaft to universal joint and reinstall fastener. Torque to 25 ft.lbs. (See Fig. 16)

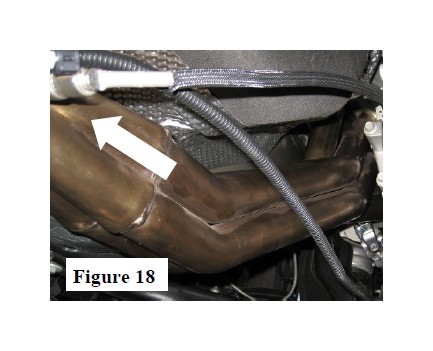

18. Inspect oxygen sensor cables and note that there are two different lengths. (See Fig. 17)

19. Install the shorter length wire extension on the drivers side front sensor and the longer wire on the passenger side front sensor. The two rear oxygen sensors do not require extensions. Reconnect all oxygen sen-sors to the factory wire harness. (See Fig. 18)

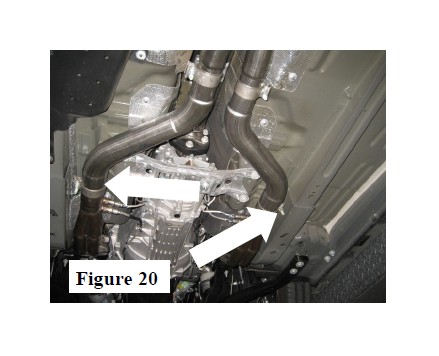

20. These headers are designed to work with Borla part #140629 or 140630 cat-backs. There are optional adapter tubes available that will allow the headers to work with the OEM, Borla 2.5”, or other aftermarket 2.5” exhausts (Part #60566 shown in Fig. 19)

21. The adapter tubes are installed using the supplied clamps. (See Fig. 20)

Caution!!! Never work on a hot exhaust system. Serious injury in the form of burns can result If the vehicle has been in use and the exhaust system is hot, allow vehicle to cool for at least 1 hour. Always wear eye protection when working under any vehicle.

Note: It is our recommendation that you use a hoist or hydraulic lift to facilitate the installation of your new Borla Performance Exhaust System.

Taking all under car safety precautions, lift the vehicle using a hoist or hydraulic lift. Once this has been done, you may begin the removal of your old exhaust system from your vehicle.

Note: Before removing the original exhaust system from your vehicle, please compare the parts you have received with the bill of materials provided on the previous page to assure that you have all the parts necessary for the installation of your new Borla Performance Exhaust System.

Header System Installation

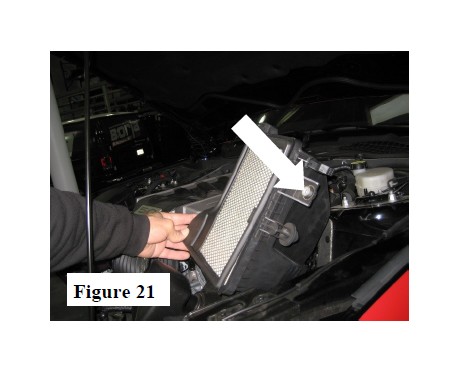

22. Place lower portion of the air cleaner assembly back in the vehicle and install retaining bolt (10mm head). Torque to 8ft.lbs. (See Fig. 21)

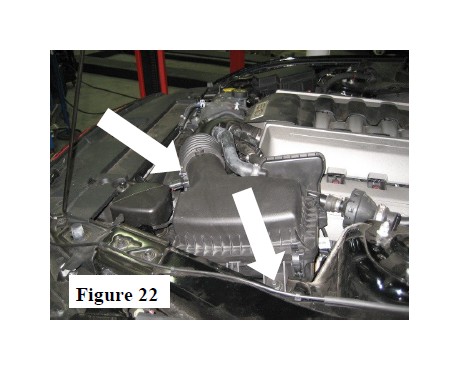

23. Place upper portion of air cleaner assembly back in vehicle. Seat intake tube and tighten hose clamp. Install sensor harness connector and re-connect acoustic tube. (See Fig. 22)

24. Connect ground cable to battery. (See Fig. 23)