How to Install Cervini's Stalker Front Bumper & Hood Kit - Unpainted (05-09 GT, V6) on your Ford Mustang

Notice: Pre fi t Before Painting. Install new, unpainted parts according to these instructions. Then remove parts, paint them and re-install.

Painted or Altered Parts are Non-Refundable!

The surface that is in contact with the 3M 2-sided tape must be cleaned with isopropyl alcohol & the temperature must be a minimum of 75 degrees F, before applying . Allow the 2-sided tape to dry 24 hours before driving.

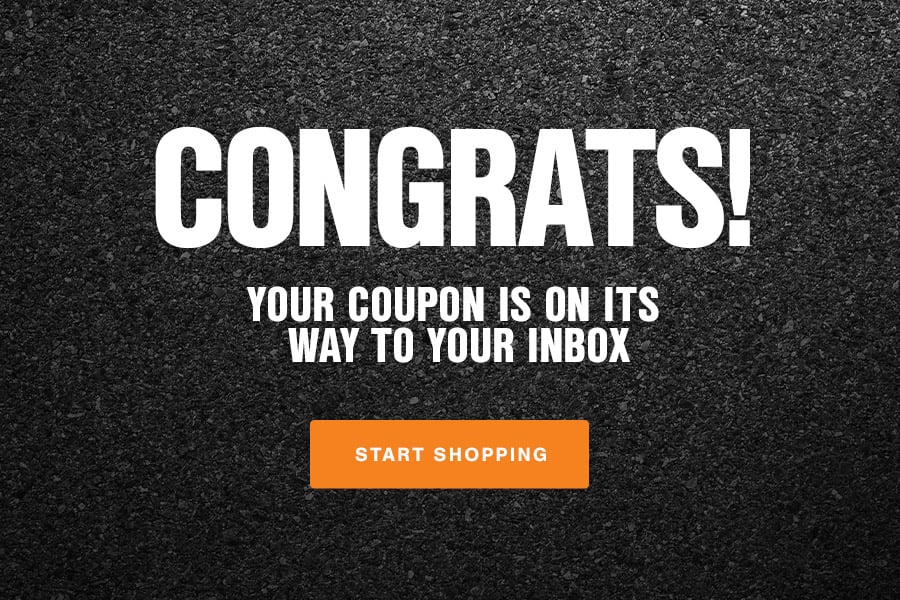

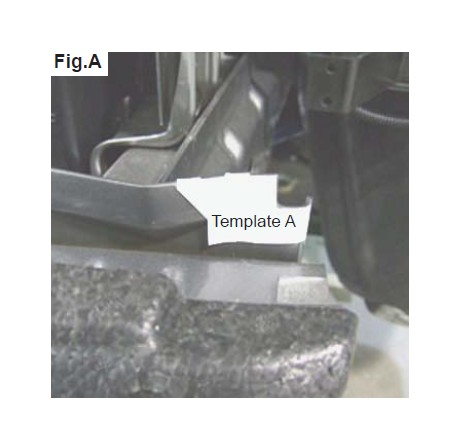

Pre-fi tting the headlights: Remove the front bumper and headlights from the car. The headlights are relocated to fi t in the stalker bumper and some cutting is involved. Cut out templates A and tape them to the corner of the impact bar as shown in fi g.A. Then, trace the out side edge of the template and cut it out with a saw-zaw as shown in fi g.B. This will allow the corner of the headlight to clear the impact bar. Cut out templates B and tape them to the top mounting point of each headlight as shown in fi g.C. Use a razor knife to score the plastic mounting tab along the edge of the template and snap off the excess peice as shown in fi g.D. This will allow the top mounting bracket to clear the radiator support.

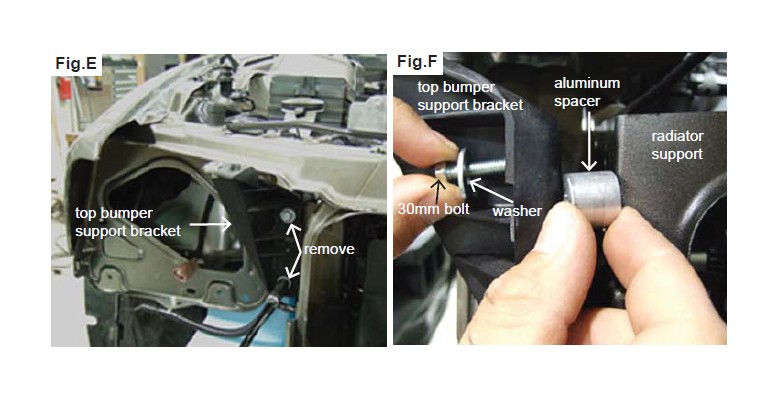

Relocating the headlights: Remove the left and right top bumper support brackets as shown in fi g.E. Then, use the supplied 30mm bolts , washers, and aluminum spacers to secure the top bumper support brackets to the opposite side of the car that they came off of as shown in fi g.F. (Put the left bracket on the right side of the radiator support and the right bracket on the left side of the radiator support.)

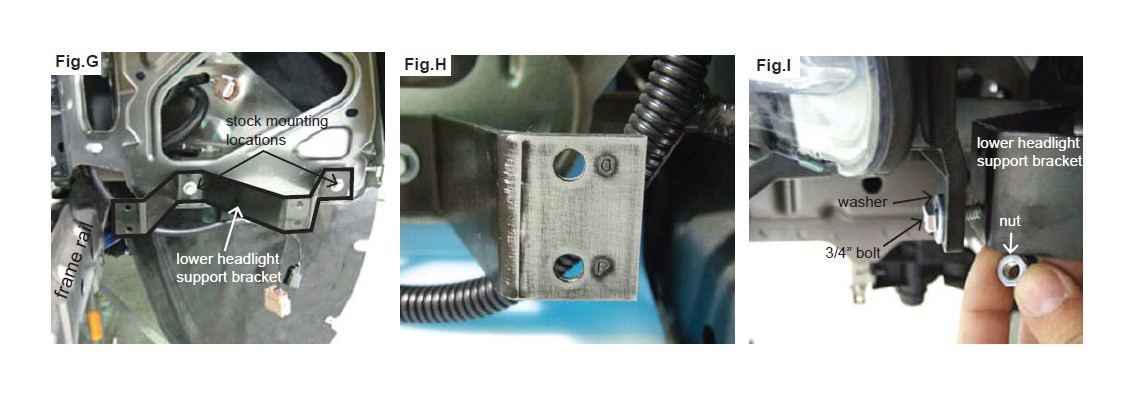

Use the factory headlight bolts to install the supplied lower headlight brackets to the factory lower headlight mounting points as shown in fi g.G. The two holes where the bottom of the headlight mounts to the bracket are stamped “D” for driver and “P” for passenger as shown in fi g.H. Use the supplied 3/4” bolts, washers, and nuts to secure the bottom of the headlight to the lower holes in the headlight bracket as shown in fi g.I. The stamping should match the side you are working on.

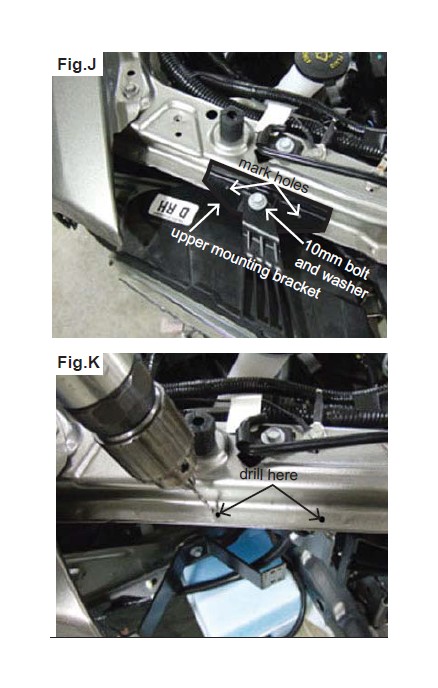

With the bottom of the headlight bolted to the bracket, use the supplied 10mm bolts and washers to secure the top of the headlight to the upper headlight mounting bracket. Push the bracket to the radiator support and mark the mounting holes with a marker as shown in fi g.J. (With the bottom of the headlight bolted to the bottom bracket, the top of the light will aline itself to the proper location on the radiator support.) Drill the marked holes out with a 1/8” drill bit as shown in fi g. K. To aviod drilling into the headlight remove it before drilling. After the holes have been drilled, use the supplied small black rivets to secure the upper mounting bracket to the radiator support.

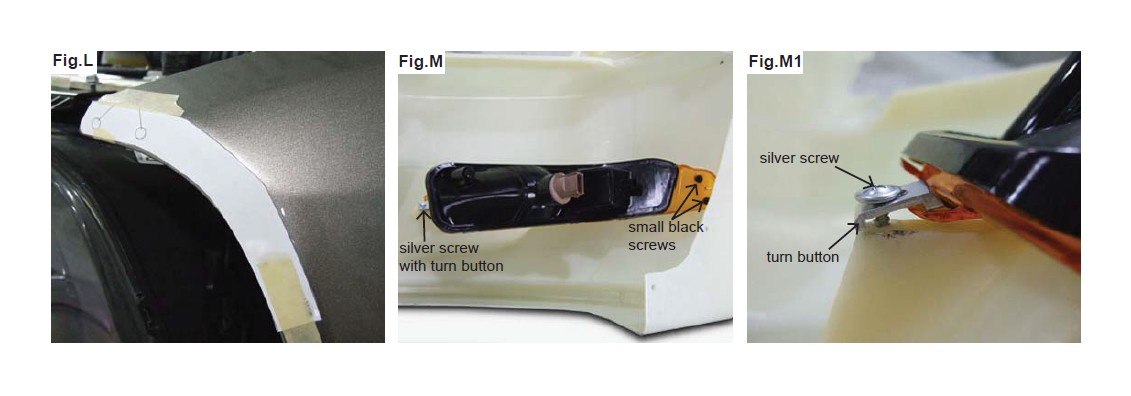

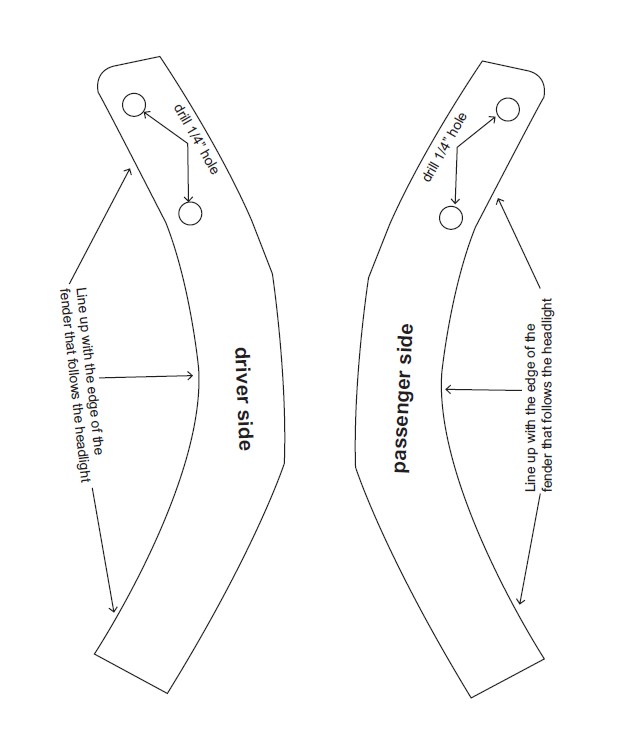

Pre-fi tting the front bumper: Cut out template C and tape it to the front of the fender as shown in fi g.L. Drill a 1/4” hole in the marked locations. Repeat the procces for the other fender. Next, install the marker lights from the factory bumper into the stalker bumper. Use two small black screws on the outside edge of the marker light and a silver screw with a turn button on the inside edge of the light as shown in fi g.M and fi g.M1.

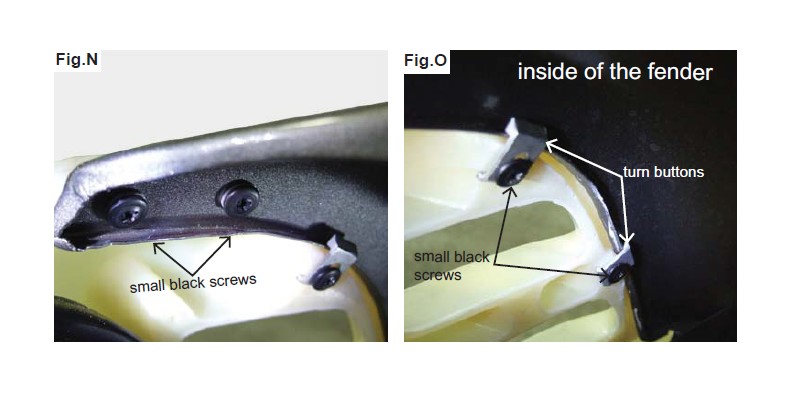

Reuse the factory hardware to install the bumper to the car. Use two small black screws to secure the top of the bumper to the fender throught the pre-drilled 1/4” holes in the fender as shown in fi g.N. Then, use two small black screws with two turn buttons to secure the outer edge of the bumper to the fender as shown in fi g.O.

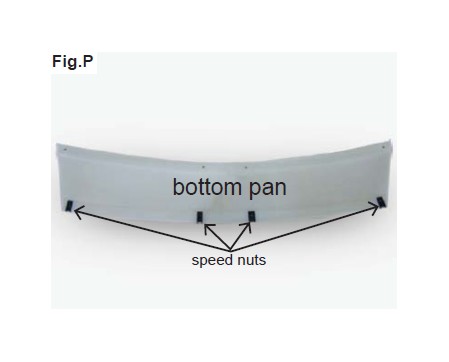

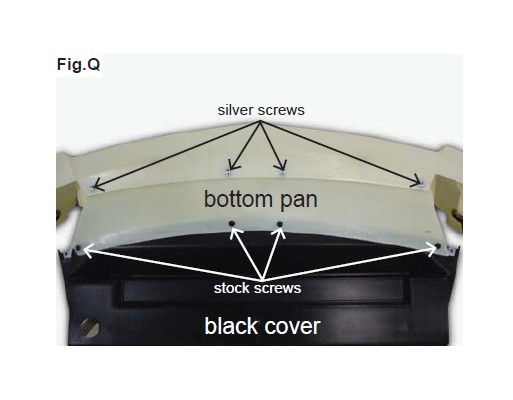

Install four speed nuts to the to the bottom pan as shown in fi g. P. Use four silver screws to install the bottom pan to the bumper. Screw the stock black cover to the bottom pan with the factory hardware as shown in fi g.Q. (The two end screw locations on the bottom pan do not match up with the stock screw holes in the black cover. Install the two middel screws fi rst. Then drill a 1/4” hole in the black cover through the pre-drilled holes in the bottom pan. Install two speed nuts to the black cover and secure it to the bottom pan.) Remove the bumper and paint it. Paint the bottom pan fl at black or semi gloss black.

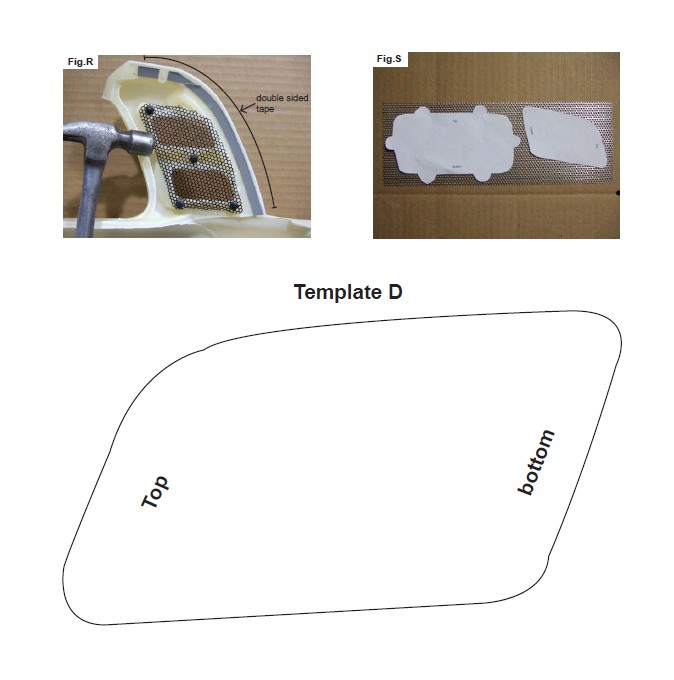

Final installation of the bumper: After the bumper has been painted, install the provided 3M double sided tape along the guidlines an 1/8” away from the outer edge of the bumper as shown in fi g.R. Do this to both sides of the bumper. Cut out template D and the template for the hood screens and tape it to the preferated screen as shown in fi g.S. Trace the out side edge of the template with a marker and cut it out of the screen with a pair of tin snips. Do this to both screens. After both screens are cut out, paint them fl at black or semi gloss black. Use the provided small black screws to install the screen to the bumper as shown in fi g.R. With a hammer, gently tap the the edges of the screen around the opening. Follow the same procedure as test fi tting the bumper to install the bumper to the car. Peel and fold about 2” of the red backing from each piece of tape, then place the bumper on the car so that the red backing is exposed and can be pulled. (This will allow you to get the best possible alignment of the part.) Pull the backing slowly. After all the backing is removed, fi rmly press the edges of the bumper to securly adhere the tape.

Template C

URETHANE PAINTING INSTRUCTIONS

VERY IMPORTANT: The following painting procedures MUST be followed EXACTLY for PROPER ADHESION and to prevent fi sh eyes.

1. To remove any mold release contaminants, clean the back of the part fi rst. Using 2 new clean rags, saturate the fi rst rag with plastic prep cleaner* and begin cleaning. Then use the second rag to remove the prep cleaner. Continuously fold both rags to their clean sides during the process. Use 3 sets of new rags throughout the process. This prevents mold release contaminants from transferring to the painted surface.

2. Repeat step one on the front of the part.

3. Rinse the part with water. Apply a generous amount of Ajax® or sand fi x* to a red scuff pad* (3M Scotch Brite Brand) and scrub the surface to be painted THOROUGHLY (especially where the 2-sided tape is installed, on the back side of the part, and all the hard to reach areas). Then rinse with water and dry. The scrubbed surface should be dull. If any shiny spots show, repeat the process on those areas.

4. Using another set of clean new rags, again clean the surface to be painted with plastic prep cleaner.

5. Spray the surface to be painted with adhesion promoter* including the areas where the 2-sided tape is installed (follow the instructions on the can for application and drying time).

6. Apply 3 to 4 coats of urethane primer* with fl ex additive* (follow the instructions on the can for application and drying time).

7. Wet sand primer with 600 grit sandpaper. Be careful not to sand through the primer. If you do, you MUST clean those areas with plastic prep cleaner, apply adhesion promoter and prime. Once the primer has dried, wet sand the areas that were touched up. Your surface is now ready for paint.

* These items can be purchased at any auto body supply store.

Note: Make sure you PRIME and PAINT the areas where the 2-sided tape is used as you would if it was the outside of the part. The tape has its best adehsion when it is applyed to a painted surface.