How to Install a Ford Racing B303 Performance Camshaft in your 1985-1995 Mustang 5.0L

Installation Time

30 minutes

Tools Required

- Torque Wrench 10 to 150 ft-lbs (must be adjustable down to at least 10 ft-lbs)

- Hex Socket - 11mm

- 3/8 Inch Thread Long Bolt (optional but suggested)

Shop Parts in this Guide

Note: This installation was done with the Ford Racing B 303 camshaft but it would be the same for any other camshaft.

Testing Proper Fitment (prior to final install):

1. Remove camshaft from the packaging

2. Inspect the camshaft and the camshaft lobes for any damage that might have occurred during shipping. Any nicks on the lobes or camshaft bearings will result in a lack of performance and can lead to undue wear of the camshaft and valve lifters.

3. Wipe off any oils that may be left over from manufacturing.

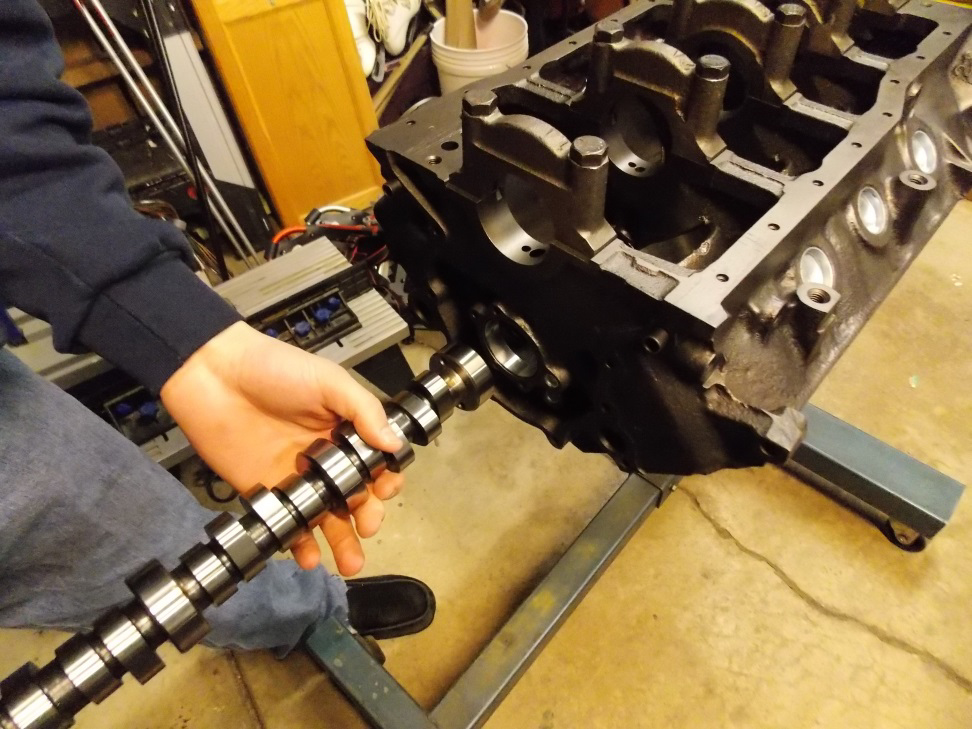

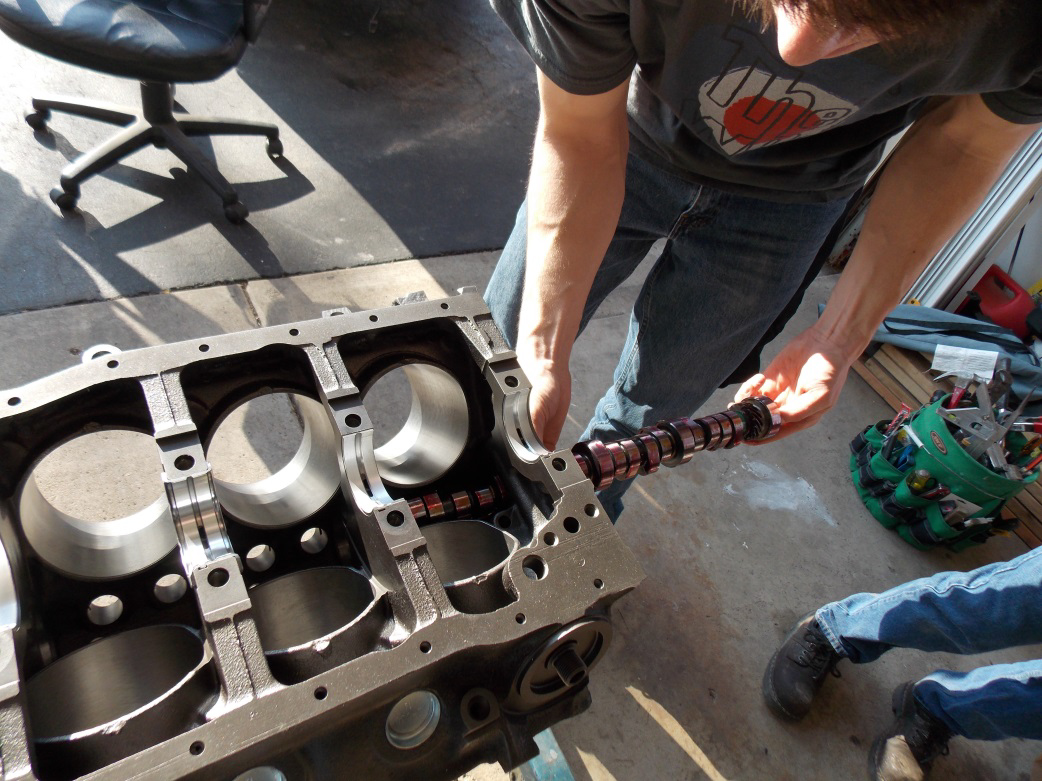

4. Slowly guide the back of the camshaft through the first set of camshaft bearings. (Figure 1)

Figure 1

It is important that you take your time while putting the camshaft into the block. Hitting the camshaft lobes on hard surfaces and damaging them will result in a loss of performance and a reduction in the life of the camshaft!

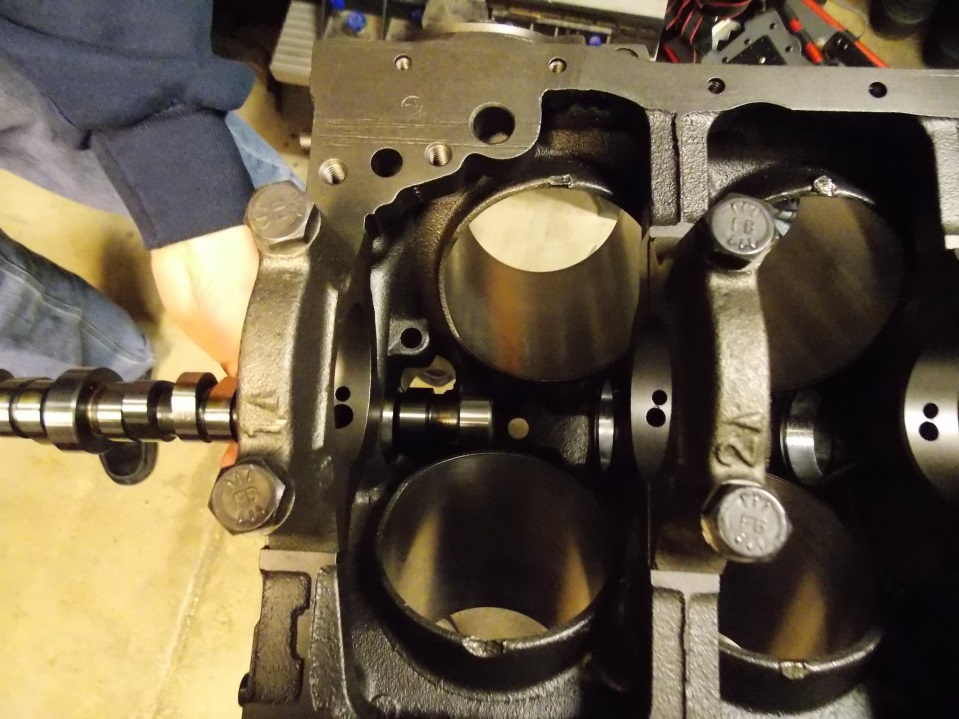

5. Continue to slowly guide the camshaft through all of the camshaft bearings.

6. Although I did not use a long bolt to help me install my camshaft, it is suggested that you use a 3/8 inch threaded bolt to give you some leverage and better control of the camshaft.

7. The bolt would be threaded into the front of the camshaft.

8. Now that you have verified that there is no problem with the fitment of the camshaft in the bearings and that the camshaft can go all the way to the back of the block you can install it for the final time.

Final Install

1. Wipe the camshaft down one final time before installing it into the block for final assembly.

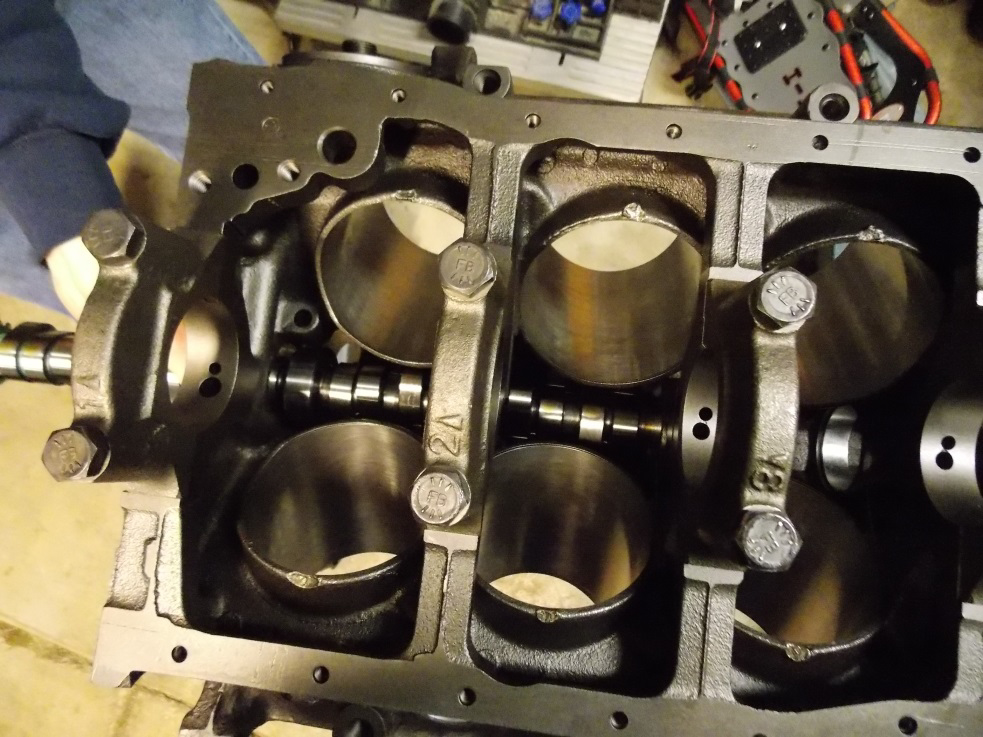

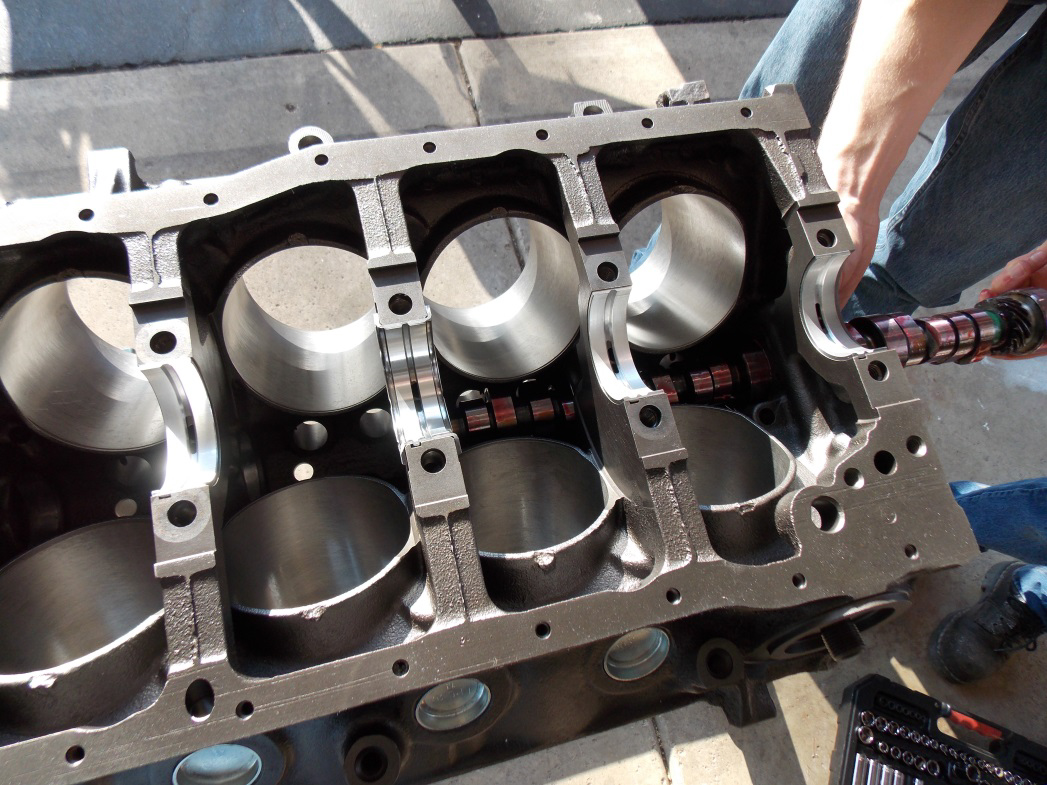

2. Apply some sort of camshaft and lifter installation lube (I used Comp Cams cam and lifter installation lube) generously to all of the lobes, the surfaces that will ride on the camshaft bearings and the camshaft gear. (Figure 2)

Figure 2

3. When standing the camshaft up on end, it is important to make sure that the camshaft does not fall over or it will most likely break.

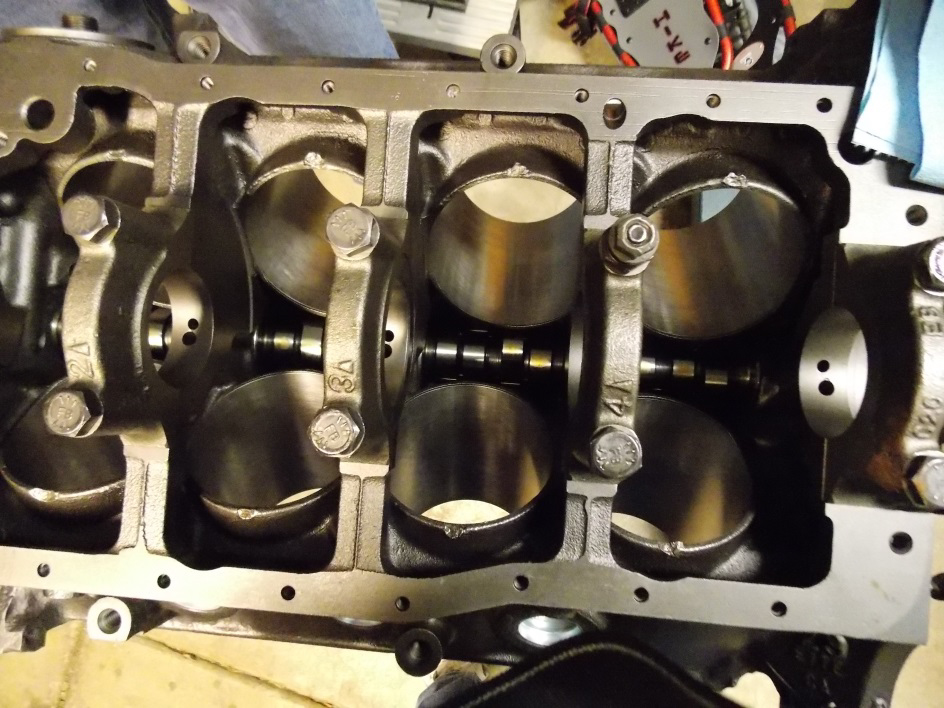

4. Install the camshaft as described in the section above and using the same caution when guiding the camshaft through the block and camshaft bearings.

5. It is important that you take your time while putting the camshaft into the block. Hitting the camshaft lobes on hard surfaces and damaging them will result in a loss of performance and a reduction in the life of the camshaft!

6. Once the camshaft has been carefully placed into the block, place the camshaft thrust plate on the front of the engine orienting the plate as shown.

7. Torque the thrust plate bolts (1/4 X 20-5/8 inches long) that hold the plate onto the front of the block to 15 ft-lbs with the 11 mm hex socket.

The camshaft is now properly installed and building of the engine can continue as planned.

Installation Instructions Written By AmericanMuscle Customer Andrew Peters 7/19/2013