How to Install a Chrome Mustang Battery Hold Down Bracket on your 2005-2009 Mustang

Installation Time

30 minutes

Tools Required

- 8 mm nut driver or socket

- Socket wrench

- 10 mm deep socket

- 5 mm hex-key wrench

Shop Parts in this Guide

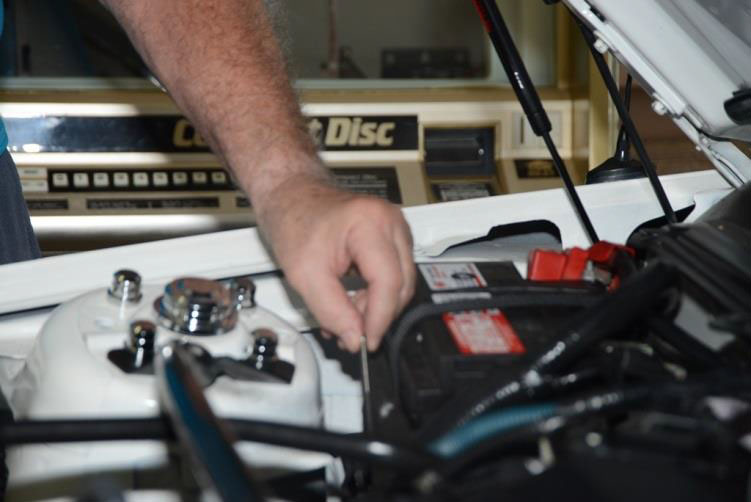

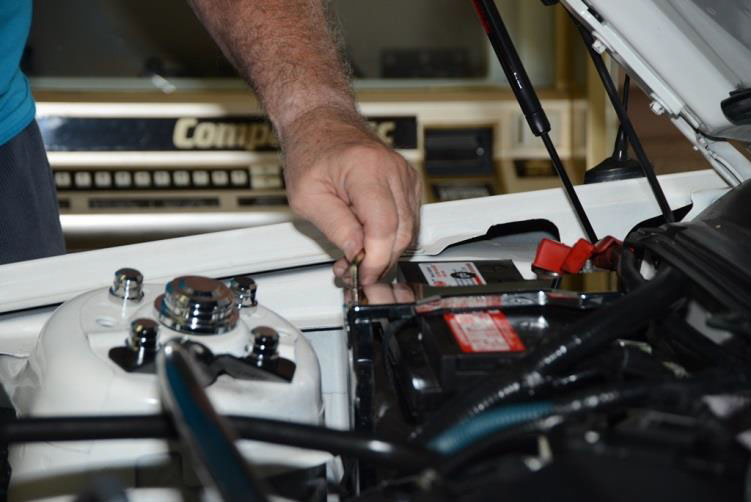

Prior to installing the hold-down here is what the battery looks like:

Use the following steps to install your new battery hold-down:

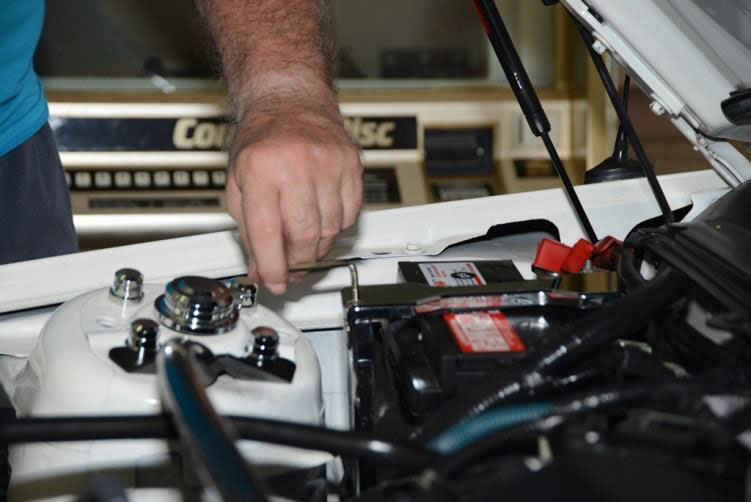

1. Remove the factory installed hold-down bolt/clamp by loosening the hold-down bolt using the 8 mm nut driver. When the bolt is free from the battery tray continue loosening the bolt from the clamp to free the clamp. Save the clamp for reinstallation.

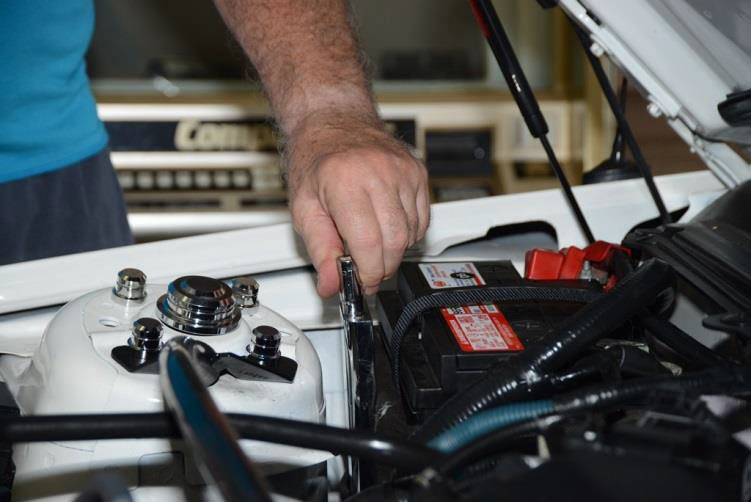

2. Hand tighten the long double threaded bolt into the battery tray in place of the factory installed battery bolt. If there is an existing cloth strap from the factory installed heat shield be sure to insert the new bolt through the hole in the strap.

3. Slide the factory battery clamp over the newly installed bolt.

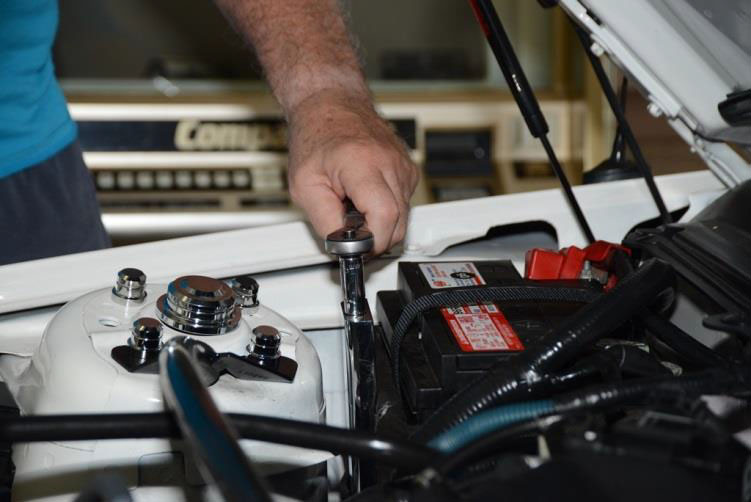

4. Slide the new billet block over the threaded bolt and push down to make sure that the factory battery clamp is set in place below it

5. Secure the billet block onto the threaded hold-down bolt using the nut/washer provided.

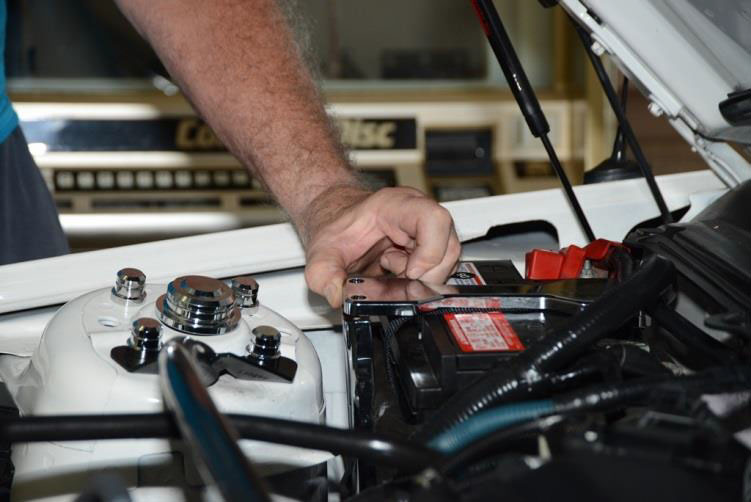

6. Attach the small rear piece onto the upper billet hold down using two hex-key screws. Then align that unit so that the front two holes are lined up with the vertical billet hold- down bar.

7. Attach the upper billet bar to the vertical front billet bar using two hex-key screws.

8. Tighten the hex-key screws with a 5mm hex-key wrench to finish the job.

9. When complete you have a beautiful addition to your under hood appearance.

Installation Guide Created by AmericanMuscle Customer Bill Turechek on 6.23.2015