How to Install Maximum Motorsports K-Member (05-14 All) on your Ford Mustang

Installation Time

1 days

Tools Required

- Standard assortment of hand tools

- Floor Jack & 4 jack stands

- 1/2” Torque Wrench

Shop Parts in this Guide

Congratulations on purchasing Maximum Motorsports’ 2005-14 Mustang K-Member.

Read all instructions before beginning work. Following instructions in the proper sequence will ensure the best and easiest installation.

Required Supplemental Items

• Mm5TR-2 Bumpsteer Kit

• MMT-11 Engine Support Brace or an engine hoist

• Mm5KM-9 Stock Crossmember Brace Adapter Kit (for 2011-14 vehicles that want to retain the OEM k-member to stock radiator core support brace)

Supplemental Installation Notes

• Alignment is required after installation

• Measuring and adjusting bumpsteer is recommended but not required

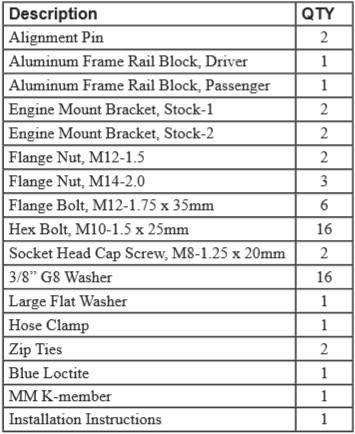

This Kit Contains

Installation

1. Support the car level on 4 jack stands. Place the jack stands underneath the rocker panel pinch welds.

NOTE: The bottom of the rocker panel pinch welds should be at least 18” off the ground to allow easy removal of the k-member.

WARNING: Do NOT lift the car up from anywhere other than the rocker panel pinch welds, or damage will occur.

2. Remove the front wheels.

3. Disconnect the negative terminal of the battery. WARNING: Permanent damage to the electric steering rack control module can occur if it is removed while the battery is still connected.

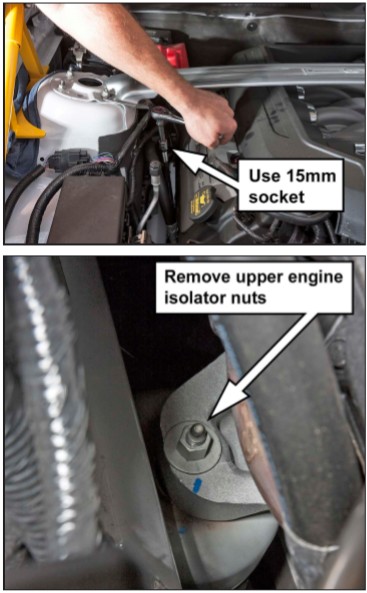

4. Remove the two upper engine mount nuts using a deep 15mm socket (one on each side of car).

5. Support the engine securely from above. The MMT-11 Engine Support Beam can be used to support the engine.

WARNING: The engine must be properly supported from above before proceeding. Do NOT use a floor jack to hold the engine up from below, as it can move and allow the engine to fall.

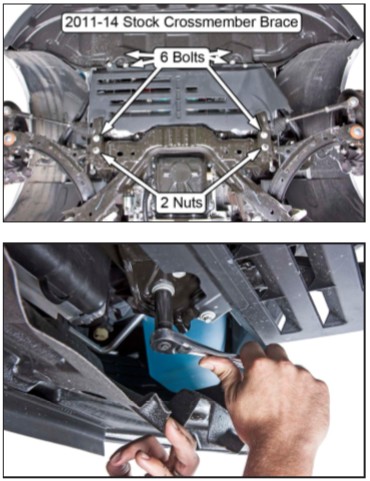

6. (2011-14 ONLY) Remove the 8 rear-most splitter screws using a 7mm nut driver.

7. (2011-14 ONLY) Remove the 6 crossmember brace bolts and 2 nuts using a 15mm socket. Gently pull down the back edge of the splitter to gain access to the front mounting bolts.

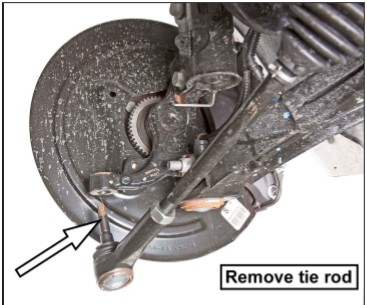

8. Remove the outer steering tie-rod nuts from the spindle using a 18mm socket. (one on each spindle).

9. Remove the outer steering tie-rods from the spindle arms. If a bumpsteer kit is already installed, remove the rod-end from the tapered stud.

10. Remove the control arm ball joint pinch bolts using an 18mm socket and 15mm wrench.

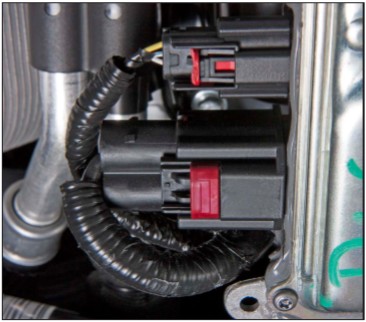

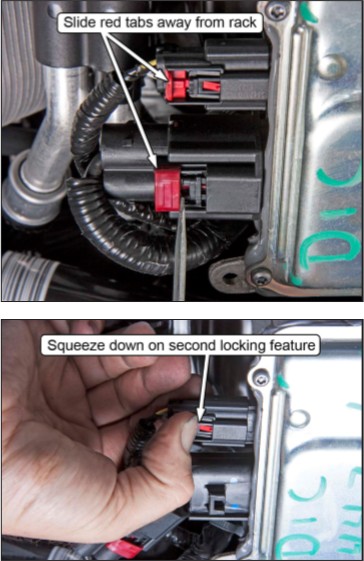

11. (Electric Rack ONLY) Disconnect both of the wiring harness plugs from the driver side of the steering rack. See the pictures below for proper removal. Each harness plug has two locking features to keep them connected to the steering rack.

12. (Electric Rack ONLY) Disconnect the harness strain relief tab on the forward, outboard corner of the power steering rack control module.

13. (Electric Rack ONLY) With the steering column unlocked, rotate the steering shaft so that the head of the bolt retaining the u-joint to the input shaft is accessible using a socket.

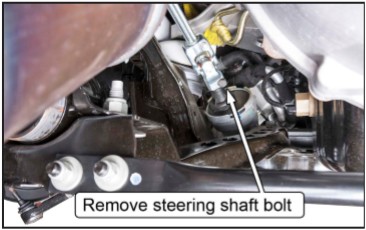

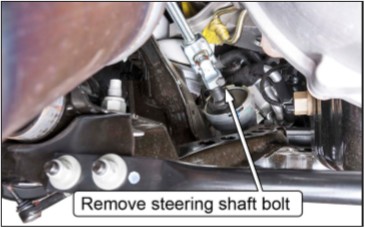

14. (Electric Rack ONLY) Lock the steering column by removing the key from the ignition.

WARNING: Do NOT rotate the steering wheel once the rack is removed.

15. (Electric Rack ONLY) Remove the bolt retaining the lower steering shaft u-joint to the steering rack input shaft using a 13mm socket.

16. (Electric Rack ONLY) Proceed to the Stock K-member Removal section.

17. (Hydraulic Rack ONLY) Remove the bolt that holds the power steering hose to the center of the k-member.

18. (Hydraulic Rack ONLY) With the steering column unlocked, rotate the steering shaft so that the head of the bolt retaining the u-joint to the input shaft is accessible using a socket.

19. (Hydraulic Rack ONLY) Lock the steering column by removing the key from the ignition. WARNING: Do NOT rotate the steering wheel once the rack is removed.

20. (Hydraulic Rack ONLY) Remove the bolt retaining the lower steering shaft u-joint to the steering rack input shaft using a 13mm socket.

Stock K-member Removal

21. Remove the four (4) k-member lower frame rail mounting pad bolts using an 18mm socket.

NOTE: These bolts require a lot of effort to remove due to the thread retaining compound used.

22. Loosen, but not remove the four (4) k-member upper frame rail mounting nuts using an 18mm socket.

23. Support the k-member with a floor jack and remove the nuts loosened in Step 22.

24. (Electric Rack ONLY) Gently lower the k-member to the ground. The spindles may need to be jiggled slightly to remove the control arm ball joints as the k-member is lowered.

25. (Hydraulic Rack ONLY) Lower the k-member, while being careful to not over-stress the attached hydraulic lines, just far enough that the two rack mounting bolts can be accessed. The spindles may need to be jiggled slightly to remove the control arm ball joints as the k-member is lowered.

26. (Hydraulic Rack ONLY) Remove the two rack mounting bolts using an 18mm socket. Retain the bolts as they will be reused.

NOTE: The rack mounting bolts will be VERY difficult to remove due to thread retaining compound used.

27. Strap the steering rack to the front swaybar using the provided zip-ties.

28. Safely lower the k-member to the ground.

Stock K-member Disassembly

29. (Electric Rack ONLY) Remove the 3 bolts retaining the steering rack to the stock k-member. Retain the bolts as they will be reused.

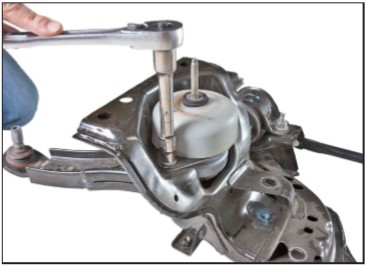

30. Remove the 4 bolts holding the engine mounts to the stock k-member using a 13mm socket. Retain the bolts, they will be reused.

31. Remove both front control arms from the stock k-member. Use an 18mm socket for the front bolts and a 21mm socket for the two rear nuts.

32. If heat shields are present on the rearward bushing shells of the stock control arms, remove them now. They will not be reused.

Aluminum Frame Rail Block Preparation

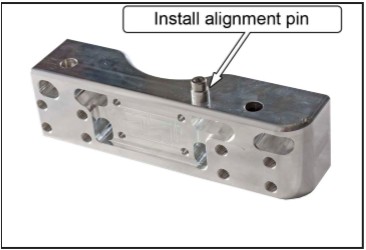

33. Insert one of the provided 8mm socket head caps screws into each of the provided alignment pins and thread them into the tops of the aluminum frame rail blocks. Tighten them to 20 Nm (16 lb-ft).

34. Lay the two aluminum frame rail blocks adjacent to each other so that the 6 threaded holes are facing you. The alignment pins should be facing up.

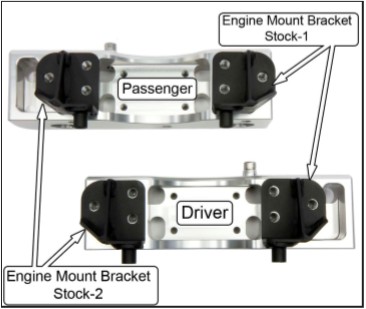

35. Locate the 4 engine mount brackets and place them on the aluminum frame rail blocks as shown. The welded on nuts should be oriented downwards.

36. Take 12 of the provided 10mm x 25mm long bolts, with a washer under each head, and apply a drop of Blue Loctite to the first few threads of each bolt. Loosely thread them into the mounting holes for the engine mount adapter plates, but do not tighten.

NOTE: The mounting holes are slightly oversized to allow for production tolerances. Torquing the bolts before installing the engine isolators may cause the mounting holes to be misaligned.

37

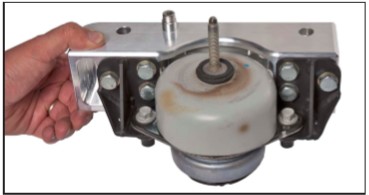

37. Install the engine isolators onto the aluminum frame rail block assemblies. Loosely thread the factory mounting bolts down, but do not torque.

38. Torque the 10mm bolts installed in Step 36 to 41 Nm (30 lb-ft) and torque the factory engine isolator bolts installed in Step 37 to 55 Nm (41 lb-ft).

MM K-member Preparation

39. Bolt the 2-point k-member brace to the k-member using 4 of the provided 10mm x 25mm long bolts with a washer under the head of each bolt. The bottom of the brace should be flush with the bottom of the k-member.

NOTE: If installing the optional Mm5KB2-21 k-member brace with transmission cooling scoop, do so at this time.

40. Torque the k-member brace bolts to 48 Nm (35 lb-ft).

41. Apply the provided Blue Loctite to the threads of the 6 provided 12mm x 35mm long flange bolts and loosely bolt the aluminum frame rail blocks to the MM K-member so that they can slightly slide around. The corner of the blocks with the large radius faces forwards and outwards.

MM K-member Installation

42. Using a floor jack or helper, lift the k-member into position so that the 4 bolts protruding from the upper frame rails slide into the aluminum frame rail blocks. Once near the frame rail, the aluminum frame rail blocks must be moved backand-forth slightly to help position the alignment pins into the locating hole and slot on the frame rails.

NOTE: Slide the driver side up into position first, then the passenger side.

NOTE: Be sure that the studs on the engine isolators have passed through their mounting holes on the engine.

43. Reuse the 4 factory nuts removed in Step 23 and loosely thread them onto the 4 upper frame rail mounting bolts so that the aluminum frame rail blocks can still be moved with slight effort.

44. Install the lower frame rail mounting bolts that were removed in Step 21 into the rear mounting pads of the k-member, but do not tighten.

45. Slide the k-member assembly forward as far as it will go.

46. Set the k-member side-to-side position by aligning the two counter bored holes on the driver side aluminum frame rail mounting block with the edge of the k-member’s upper frame rail mounting flange.

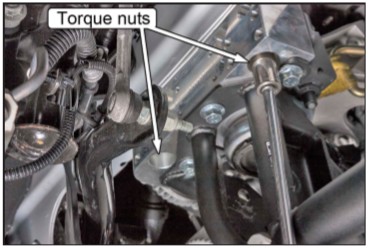

47. Torque the upper frame rail mounting nuts to 115 Nm (85 lb-ft).

48. Torque the lower frame rail mounting bolts to 115 Nm (85 lb-ft).

49. Torque the 6 flange bolts installed in Step 41 to 82 Nm (60 lb-ft).

50. Install the lower control arms into position on the k-member, using the lower set of mounting holes. Reuse the factory hardware to attach the rear pivot bushings to the k-member.

51. Install the lower control arm forward pivot mounting bolts, removed in Step 31, into the lowest control arm mounting holes of the k-member, along with one of the provided 14mm flanged nuts.

NOTE: Dot not tighten the forward pivot bolts yet.

52. Torque the rear pivot bushing mounting hardware to 185 Nm (136 lb-ft). NOTE: The rear pivot bushing must be torqued first to remove any preload in the rubber bushings.

53. Torque the front pivot bushing mounting hardware to 205 Nm (151 lb-ft).

54. Reinstall the steering rack, making sure to slide the steering shaft u-joint onto the input shaft of the rack.

55. Install the two factory 12mm rack mounting bolts into the steering rack housing and through the mounting bosses on the k-member (removed in Step 26 for hydraulic racks & Step 29 for electric racks).

NOTE: These are fine threaded bolts.

56. Use the two provided 12mm-1.5 flange nuts to secure the steering rack mounting bolts. Torque the nuts to 115 Nm (85 lb-ft).

57. (Electric Rack ONLY) Place the provided large flat washer onto the 14mm steering rack mounting bolt and insert from the top of the rack. Use the remaining provided 14mm flanged nut and torque to 115 Nm (85 lb-ft).

58. Reinstall the steering shaft u-joint pinch bolt and torque to 25 Nm (18 lb-ft).

59. (Electric Rack ONLY) Reconnect the two wiring harness plugs and strain relief tab removed in Steps 11 to 12.

60. Insert the control arm ball joints into the spindles. It may be necessary to loosen/remove spindle-to-strut mounting bolts if the control arm cannot be pushed down far enough to engage the ball joint.

61. Reinstall the spindle ball joint bolts/nuts and torque to 103 Nm (73 lb-ft).

62. (Hydraulic Rack ONLY) Use the provided hose clamp to secure the power steering hose relief bracket to the steering rack. Slip the hose clamp through the mounting slot of the bracket, then around the steering rack housing, and firmly tighten.

63. Install an Mm5TR-2 Bumpsteer Kit. Place the following spacers between the top of the rod end and the bottom of the stud’s shoulder: 0.03”, 0.24”, and 0.48”. The remaining spacers must be placed below the rod end.

64. (2011-14 ONLY) If the stock crossmember brace removed in Steps 6 to 7 is being reused, a Mm5KM-9 Crossmember Brace Adapter Bracket kit should be installed at this time.

65. (2011-14 ONLY) Install the 8 rear-most splitter screws removed in Step 6.

66. Lower the engine onto the engine isolators and remove the MMT-11 Engine Support Brace.

67. Reinstall the two upper engine isolator nuts and torque to 63 Nm (46 lb-ft)

68. Reinstall the front wheels and safely lower the vehicle to the ground.

69. Torque to wheels to the factory specifications.

70. Reconnect the battery terminal.

71. Have the vehicle properly aligned.

72. Test drive and enjoy!