How to Install Maximum Motorsports K-Member Brace (79-95 All) on your Ford Mustang

Installation Time

1 hours

Tools Required

- 2 large C-clamps

- 4 jack stands

- Bumpsteer gauge

- Engine hoist or support truss

- Floor jack

- Masking Tape & Pen

- Plumb bob(s)

- Spring compressor (internal type)

- Tape measure

- Torque wrench

- T-55 Torx Socket

- Typical selection of hand tools

Shop Parts in this Guide

Read all instructions before beginning work. Following instructions in the proper sequence will ensure the best and easiest installation.

Thank you for purchasing the Maximum Motorsports’ K-member. The MM K-member is designed to maximize the performance of your Mustang’s front suspension. You will find many features that set our K-member apart from the rest.

• There are two sets of control arm mounting holes—that means the roll center height and camber curves can be optimized for your car’s ride height.

• The Ackerman steering geometry is adjustable and optimized.

• There are two engine mounting locations—stock or rearward 1".

• The wheelbase is lengthened by 0.75". Front to rear weight distribution is improved by 1%. Caster is increased by 2 degrees for improved cornering grip, tire wear, and high speed stability.

• The MM K-member maintains the stock percentage of anti-dive geometry. Our testing has proven that increased anti-dive will hurt the car’s ability to absorb bumps during braking. Any less anti-dive will cause excessive pitching during braking.

• The K-member is the load path into the chassis for all front wheel steering, cornering, and braking forces—it must be engineered for strength and stiffness. This is a fully triangulated design, using round or rectangular tubing where each is appropriate, and shear planes where necessary. This robust design is intended to last the life of your vehicle and provide maximum return on your investment.

• Of all the K-members available, MM’s is the most rigid, and yet our testing has shown that a K-member brace is still required. We include a brace to ensure maximum suspension rigidity during cornering.

• The MM K-member provides increased clearance for engine and suspension service, and over 1” greater header clearance in critical areas.

Proper installation of the MM K-member will require the use of the following parts:

• Tubular front control arms.

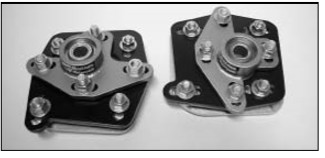

• Caster/Camber plates.

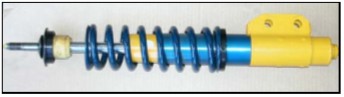

• Front Coil-Over conversion kit.

• MMST-6 Spherical Rack Bushings.

• MMST-8 Rack Spacers (Manual Racks ONLY).

• Adjustable Tie-Rod ends.

• MM Relocation Kit for the front Swaybar, when using the MM forward-offset control arms.

We recommend the following parts to accompany the installation of a K-member:

• Solid steering shaft

• Shorter aftermarket urethane swaybar end links

• MM Front Swaybar Bracket reinforcements (1979-1993 cars)

• MM Strut Tower Brace

• High performance struts to match your spring rate

Planning ahead for the Engine Setback Option

If you are going to relocate your engine rearwards 1”, there are some things that need to be checked before you start the installation of the K-member.

Remove the two nuts which hold the transmission mount to the transmission crossmember. There needs to be at least 1” between the back of each stud and the rear of each slot. If there is not this amount of clearance, the transmission crossmember needs to be removed from the car and the slots elongated to allow the transmission to be moved rearwards by 1”.

With the rear suspension of the car at ride height, unbolt the driveshaft from the differential. Push the driveshaft forward as far as it will go into the transmission. Hold the driveshaft flange parallel to the differential pinion flange. Measure the gap between the two. This is the amount of driveshaft plunge available. If there is less than 2” of available plunge at this time, you must have the driveshaft shortened. Make these measurements very carefully. If the driveshaft ever bottoms out in the transmission, very bad things will happen.

Clearance between the headers and the firewall will need to be checked. Full length 1-3/4” headers will usually not fit without modifications. The firewall can be massaged with a large hammer to gain enough clearance to allow them to fit. Mark out the area where the heater box resides behind the dash on the engine side of the firewall. Be careful to not hammer in this area of the firewall as you are likely to crack the heater box. Clearance between the headers and the steering shaft will also need to be checked. Some aftermarket steering shafts have set screws in their universal joints that may need to be shortened for clearance.

The H-pipe will usually need to have 1” removed between the front collectors and the crossover tube.

The transmission tunnel may need to be modified to clear the transmission shifter housing.

Spindle Compatibility

For best results, we recommend the 1996 Mustang spindles in all applications. This will result in the lightest, stiffest steering setup for minimum wandering and maximum responsiveness. The reason is because the steering arm on the 1987-95 spindles is located higher than on the 1996 spindles; therefore the 1987-95 spindles require an additional 1” of bumpsteer spacer between the steering arm and the tie-rod end than the 1996 spindles.

Swaybar Location

If you use the MM zero-offset front control arms, the front swaybar can remain mounted in the stock location. If you use the MM front control arms which have the ¾” forwardoffset, the front swaybar must be mounted with the MM Relocation Kit for the Front Swaybar (MMFSB-50 or -51). The relocation kit moves the swaybar forward 3/4” to compensate for the more forward location of the swaybar mounting hole with the forward-offset control arms.

Stock K-member Removal

1. Disconnect the ground terminal at the battery.

2. Start with the vehicle on a flat, level surface.

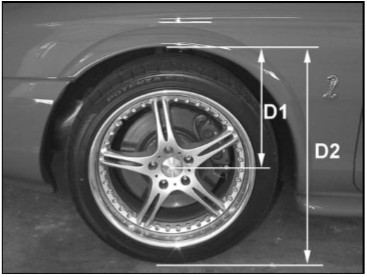

3. Measure the distance from the center of the front wheel to the fender lip. Record this dimension as D1. Also measure from the ground to the front fender lip. Record this dimension as D2. These dimensions will be needed later.

4. Jack up the car and place it safely on four jack stands as high as possible. Two stands should be placed under the front subframe, just behind the radiator as shown. The other two stands should be placed under the rear axle.

5. Level the car by measuring from the bottom of the rocker panels to the ground. Adjust the height of the jackstands to get the car as level as possible.

6. The engine needs to be supported from above. There are two ways of accomplishing this. One is to use an engine hoist. The second is to use an engine support truss. The second option makes the job much easier because there will be more room under the car.

7. Attach the supporting chains or straps to the front accessory brackets or to the headers.

8. This engine support truss lays across the chassis just inboard of the fenders, and requires the removal of the engine accessory belt.

9. Remove the front wheels.

10. Remove the front caliper and hang it securely. Do not let the caliper hang from the brake hoses as this can cause unseen damage to the hose. Steel braided hoses are especially susceptible to damage if the caliper is dropped or allowed to hang unsupported.

11. Remove the front brake rotor.

12. Remove the front swaybar end link.

13. Loosen the front strut to spindle bolts, but do not remove them.

14. Loosen the tie rod end nut but do not remove it.

15. Spray the outer tie-rod end taper stud with penetrating oil.

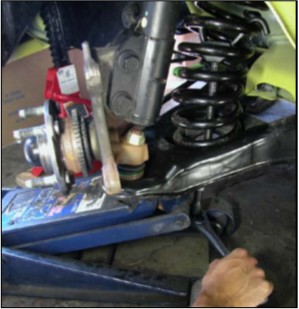

16. Turn the spindle to its maximum toe-in position. Place a floor jack under the control arm near the ball joint. Leave about ½” of clearance between the floor jack and the control arm.

17. Loosen the lower ball joint nut until the top of the nut is flush with the top of the ball joint stud.

18. Spray the ball joint taper with penetrating oil.

19. Free the tie-rod end by hitting the front end of the steering arm with a large hammer.

20. Remove the nut and tie-rod end from the steering arm.

21. Strike the spindle just below the strut, where the ball joint attaches to the spindle, with a large hammer. Do this until the ball joint taper comes free from the spindle.

22. Use an internally mounted coil spring compressor and compress the front coil spring. Most auto part and equipment rental stores rent this type of spring compressor.

23. Raise the control arm 1/2” with the floor jack. Remove the ball joint nut completely.

24. Remove the strut to spindle bolts completely.

25. Remove the spindle.

26. For easier access, remove the strut from the car.

27. Carefully lower the floor jack until the front spring becomes unseated from the upper spring perch.

28. With the floor jack completely removed from under the control arm, release the internal spring compressor to free the spring from the control arm.

29. Repeat steps 10 to 28 for the opposite side of the car.

30. Remove the pinch bolt that holds the steering shaft to the input shaft of the steering rack. Some factory K-members have a hole which allows easier access to the pinch bolt.

31. Remove the two bolts that hold the steering rack to the K-member. Pull the steering rack forward until it is just below the swaybar. To keep the steering rack out of the way, zip tie or wire it underneath the swaybar. It is not necessary to disconnect any hoses from the steering rack.

32. Remove each of the retaining nuts holding the two motor mounts to the K-member.

33. Raise the engine about with the engine hoist or the engine support truss. Raise the engine just far enough that the motor mounts do not touch the K-member. Check for any wires that may be attached to the K-member. Both of the O2 sensor wires are usually attached to the K-member. Locate the O2 sensors in the H-pipe. Follow the wires back to the K-member and disconnect them from the K-member.

34. Support the K-member with a floor jack in the center. Loosen, but do not remove, the four bolts that hold the K-member to the frame near the upper spring pockets.

35. Remove the four bolts at the rear of the K-member.

36. Remove the four bolts near the spring pockets completely. Have a second person stabilize the K-member while doing this. Slowly lower the floor jack and K-member while also checking for any objects that may hang up on the K-member. Lower the K-member to the floor and remove it from underneath the car.

Now is an excellent time to clean off the bottom of the engine and/or replace that leaking oil pan gasket. Don’t be tempted with a cheap cork gasket! Get the latest gasket from Ford which has metal inserts and won’t leak.

MM K-member Installation

37. Loosen both of the bolts that hold each of the two engine mounts to the engine block by about 4 turns each.

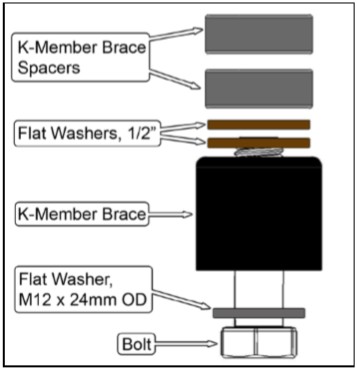

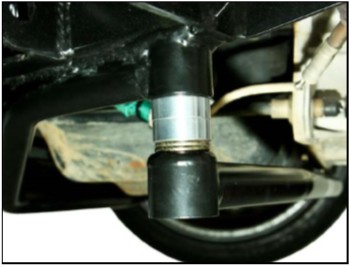

38. Attach the supplied MM K-member brace to the MM K-member. If you are using a stock oil pan and shorty headers, the K-member brace should be installed flush with the bottom of the K-member using the 1/2” X 1-1/4” G8 bolts with an M12 X 24mm OD washer under the head of each bolt . If you have an aftermarket oil pan or long-tube headers, space the brace down as far as possible using the provided spacers, the 1/2” Flat washers, and the 1/2” X 2” long bolts with an M12 x 24mm OD washer under the head of each bolt. Snug, but do not fully tighten the bolts. The K-brace tube is offset. Bias it forward or rearward as needed for clearance.

NOTE: Some installations may not require spacers. Your requirements may vary.

39. Place a board on the floor jack and place the K-member on the board. The K-member should be located so that it is balanced on the center of the jack pad. Slowly raise the K-member into position underneath the front of the vehicle.

40. Guide the engine mount studs into the appropriate slots in the K-member. Check to make sure that nothing is getting pinched as you raise the K-member.

41. Once the K-member is within ½” of the frame rails, stop and install all eight bolts that hold the K-member to the chassis. Note that the each of the two pairs of rearward bolts thread into nuts captured by a single removable nut plate.

42. Tighten the four upper bolts above the control arm mounting holes until the K-member is seated firmly against the frame rails. Do not tighten the four rearward bolts.

Squaring the K-member

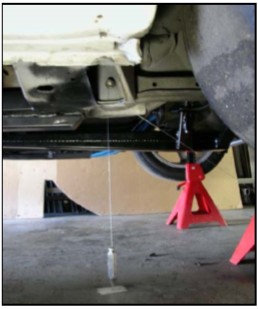

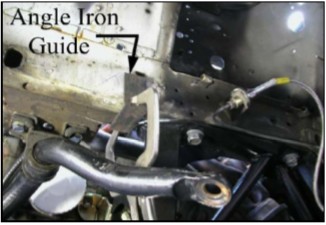

It is necessary to adjust the position of the K-member so it is square in the vehicle. This is accomplished with the aid of a plumb bob (two plumb bobs makes the job much easier), two C-clamps, a tape measure, a pen, and the two supplied angle iron guides.

NOTE: You must square the MM K-member to the rear suspension pick-up points. To do so, the rear control arm to chassis bolts must installed in Ford’s original orientation. Ford installs the bolts through the chassis from the inboard side of the frame rail with the threaded end toward the outside of the chassis. Check the orientation of these bolts. If necessary, reverse their orientation.

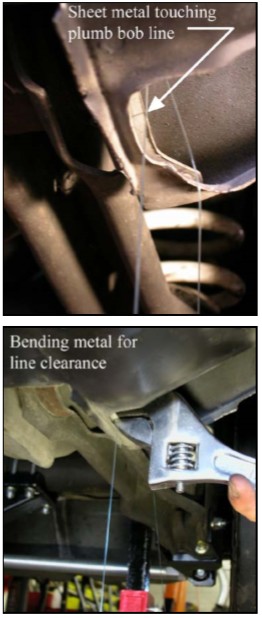

43. Wrap the plumb bob line ½ turn around the front (chassis end) mounting bolt of the rear lower control arm. This bolt can be accessed through the hole in the torque box just in front of the rear tire. The line should be over the threads of the bolt, all the way against the nut face. Hang the plumb bobs in the exact same manner on both sides of the car. For example, make sure the line is hanging off the bolt from the forward side or rearward side on both sides of the car. Make sure that the line hangs down from the bolt without touching any bodywork. If it does touch the chassis, bend the interfering metal out of the way.

44. Adjust the height of the plumb bob until it is very close to touching the ground. Tie a large weight to the free end of the line as an anchor, or secure the line by taping it to the chassis.

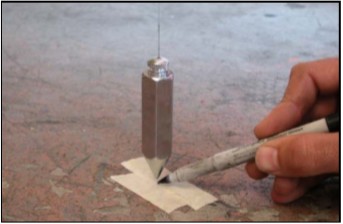

45. Stick pieces of masking tape to the ground directly under the tip of each plumb bob.

46. Wait for the plumb bob to stop swinging. Mark the position of each plumb bob by placing a small dot on the tape directly under the tip of the plumb bob.

47. Remove the plumb bobs.

48. Go to the front of the car. Pass the plumb bob line through the very small hole located below the most rearward, lower mounting hole for the front control arm. Pass the plumb bob line through from front to rear.

49. Adjust the height of the plumb bob until it is very close to touching the ground. Make sure the line is centered at the lowest point of the hole. Place a piece of masking tape on the back side of the control arm tab on the K-member to fix the height of the plumb bob.

50. Stick pieces of masking tape to the ground directly under the tip of each plumb bob.

51. Wait for the plumb bob to stop swinging. Mark the position of each plumb bob by placing a small dot on the tape directly under the tip of the plumb bob.

52. The measurements done in the following steps will require two people. Measure the distance between the two dots on the ground on the left side of the car.

53. Take the same measurement between the two dots on the right side of the car.

54. These two distances should be the same. If the distances are not equal, on the side of the car with the shorter distance, loosen the two bolts holding the K-member to the frame. On the side of the car with the longer distance loosen the rearward bolt only.

55. Using a rubber mallet or a pry bar, move the K-member on the shorter side forward enough to equalize the distances on both sides of the car. Snug the upper four K-member mounting bolts.

56. Make new dots on the ground to mark the new position of each of the front plumb bobs.

57. Re-measure the distances between the dots on both sides of the car and compare them.

58. Repeat this procedure until the distances match each other within 1/16”.

59. If you are unable to move one side of the K-member forward enough, you may have to move the opposite side rearwards.

60. If you think you may have disturbed the car on the jack stands, place the plumb bobs back onto the rear control arm mounting bolts and check that the dots on the masking tape are still indicating the correct position of the rear plumb bobs.

61. Once the wheelbase on each side of the car is equal, the next step uses the supplied angle iron guides. Clamp one angle iron guide underneath the frame rail directly in front of, and touching, the K-member. Use a C-clamp or large vise grips.

62. Repeat this on the other side of the car. These angle iron guides form stops to keep the K-member aligned front to rear while centering the K-member side to side in the following steps.

63. Measure the diagonal distances between the four dots on the ground. Record the distance from the dot on the front driver side of the car to the dot on the rear passenger side of the car as D3. Record the distance from the dot on the front passenger side of the car to the dot on the rear driver side of the car as D4.

64. If D4 is greater than D3, the K-member needs to be moved towards the driver side the car. If D4 is less than D3, the K-member needs to be moved towards the passenger side of the car.

65. Scribe a line in the fore/aft direction on the angle iron guide on one side of the car. Extend this line rearwards straight onto the bottom of the K-member flange (the flat plate which bolts to the chassis). This will be used as a reference to determine how far you have moved the K-member.

66. Loosen the four bolts holding the K-member to the frame. Tap the K-member from the side until it has moved the appropriate distance. This is easiest done with a large dead-blow hammer.

67. Tighten the 4 bolts, mark new dots with the plumb bobs and re-measure distances D3 and D4.

68. Repeat these steps until the difference between D4 and D3 is 1/8” or less. This means the K-member is centered left to right under the car.

69. Once the K-member is properly positioned, place the plumb bobs back onto the rear control arm mounting bolts and check that the dots on the masking tape are still indicating the correct position of the plumb bobs. If not, this indicates that the car has shifted on the jack stands. If it has shifted, you will have to go through the squaring procedure again.

70. Torque the four upper K-member bolts to 89 ft/lbs.

71. Torque the four rearward bolts holding the K-member to the chassis to 72 ft/lbs.

72. Remove the C-clamps and angle iron guides.

73. Tighten the bolts holding the engine mounts to the engine block to 50 ft/lbs.

74. Gently lower the engine down onto the K-member, making sure not to pinch any lines or wires. Watch header clearance to avoid denting a header tube. Install the engine mount nuts onto the engine mount studs and torque to 95 ft-lbs.

75. Remove the engine hoist or engine support truss.

76. If you spaced the K-member brace down in Step 38, check the oil pan and header clearance to the K-member brace. If possible, remove spacers from between the K-member brace and K-member. Do this until the K-member brace is as high as possible, but still has 1/4 inch of clearance to your oil pan and headers. If necessary, use the shorter 1-1/4” bolts to prevent the bolts from bottoming in the threaded holes. Tighten the two Grade 8 bolts to 100 ft-lbs.

Control Arm Location

The MM K-member has two sets of mounting holes for the front control arms. The lower set is raised 1 inch from the stock location. These holes should be used if the car is lowered 1 - 2 inches. The upper set of holes is raised 2 inches from the stock location. If the vehicle is lowered more than 2 inches, we recommend using the upper set of holes.

Control Arm Assembly

See the instructions which came with your MM Front Control Arms.

Control Arm Installation

All MM K-members built after 3/11/2008 include a set of our MMF-2 Low Profile Front Control Arm Bolts that are intended to be used on the forward pivots of the front control arms. Please follow the directions carefully to ensure proper installation.

77. Grease all exposed faces of the front control arm bushings using Prothane’s Super Grease supplied with your MM Front Control Arms.

78. Slide the control arm into place on the K-member with the sway bar mount facing toward the front of the car.

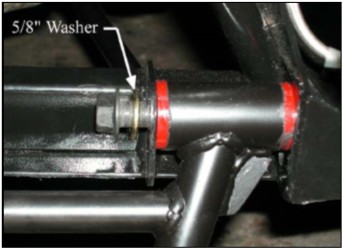

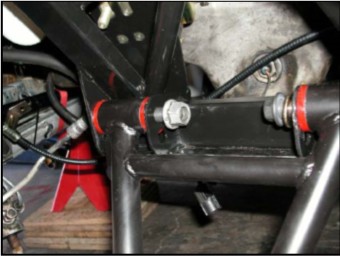

79. Install one of the provided MM Low Profile Front Control Arm Bolts into the forward pivot of each control arm. Install the stock pivot bolts into the rearward pivots using a supplied 5/8” washer under the head. The washer prevents the rearward bolts from bottoming out before the nut is fully tightened.

NOTE: The MM K-member requires all pivot bolts to be installed with the bolt heads toward the front of the car.

80

80. Thread a factory nut onto each pivot bolt.

81. Hold the head of the MM Low Profile Front Control Arm Bolt stationary using a T-55 Torx socket and tighten the nut. Torque the nut to 148 ft-lbs.

NOTE: The MM Low Profile Front Control Arm Bolts require holding the head of the bolt in place with a T-55 Torx socket while tightening the nut. Do NOT turn the Torx head to tighten. Instead, hold the bolt still with the T-55 socket and turn the nut to tighten.

NOTE: If you are NOT using MM Front Control Arms, consult the manufacturer of your control arms for their recommended control arm pivot bolt torque. The crush tubes of other brands’ front control arms may not be capable of withstanding the factory specification of 148 ft-lbs of torque. We do not endorse torquing the pivot bolts less than 148 ft-lbs.

82. Torque the remaining MM Low Profile Front Control Arm Bolt using the same procedure described above.

83. Torque the rearward, stock control arm pivot bolts to 148 ft-lbs.

Steering Rack Installation

The MM K-member is specifically designed to use the MMST-6 Aluminum Spherical Rack Bushings. Use of other rack bushings may not yield optimum Ackerman steering geometry and may cause the steering to bind.

Also, versions of the MM K-members prior to 3/11/2008 did not include the MMF-2 Low Profile Front Control Arm Bolts. If you do not have these bolts, we highly recommend contacting Maximum Motorsports and ordering a set.

NOTE: If you are using a manual steering rack, you MUST install the MMST-8 spacer kit to increase clearance between the rack and K-member.

84. The MMST-6 Aluminum Spherical Rack Bushings must be in place on the steering rack prior to the next step. See the newest instructions (9/11/2009 or newer) that came with the MMST-6 bushings to install them into the rack. The MMST-6 bushings allow for three different rack offsets. In all cases, we recommend using the largest offset possible to position the rack as high as possible. This will minimize the height of the spacer stack under the spindle’s steering arm.

85. Untie the steering rack from the swaybar. Raise the steering rack into position while engaging the steering shaft onto the steering rack input shaft. The stock steering shaft will only engage onto the rack’s input shaft in one orientation. Be sure the steering shaft is fully engaged on the splines of the input shaft. On 1993 and earlier cars, the steering column may need to be extended slightly out of the firewall for this. To extend the steering column, grab the exposed portion of the column (where the steering shaft attaches to it) with Vise-Grip pliers, and pull it towards the front of the car. Pull on the inner rotating portion of the column, not the outer fixed portion. On 1994-95 cars, the steering shaft itself includes the collapsible portion, rather than the steering column. The steering shaft will extend slightly when pulled.

86. Insert the steering rack bolts through the rack bushings from the front of the rack. Slide each bolt through the steering rack mounting sleeve in the K-member.

NOTE: Be sure that the steering rack bolt is passing through the same offset hole in each rack bushing as determined using the latest MMST-6 installation instructions.

87. Install the factory nuts onto the steering rack bolts.

88. When setting the engine back 1”, with some aftermarket oil pans there may be interference between the steering rack and the oil pan’s front sump. This can be fixed by doing the following: On the steering rack, carefully bend the metal pressure line that goes into the front (at the center) of the rack housing downwards at about a 30° angle to gain clearance between this line and the front sump.

89. Snug the factory nuts on the steering rack bolts. When using the offset holes in the steering rack bushings, ensure that the bushings are oriented correctly. The three holes in each bushing should be in a vertical line with the center of the bushing.

NOTE: If you are using a manual steering rack, you MUST install the MMST-8 spacer kit to increase clearance between the rack and K-member.

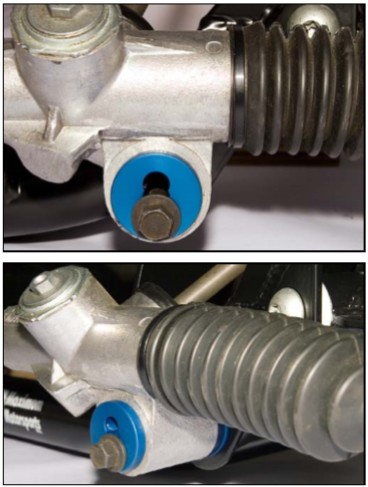

90. Check the orientation of the clamps that secure the rubber rack bellows boots to the rack housing. If the clamp bolt is installed towards the K-member, as shown below, the clamp bolt may prevent the steering rack from being fully seated against the K-member. If necessary, rotate the position of the boot clamps.

91. Torque the steering rack mounting bolts to 55 ft-lbs.

92. If you are using the stock steering shaft, torque the steering shaft pinch bolt to 25 ft-lbs.

93. If you are using an aftermarket steering shaft, torque the steering shaft pinch bolt or set screws according to the steering shaft manufacturer’s instructions.

94. If using the forward-offset MM control arms, now is the time to move the swaybar forward 1.0” with the appropriate MM Relocation Kit (MMFSB-50,-51).

95. An adjustable outer tie-rod end style bump steer correction kit must be installed prior to the next step. We recommend a bolt-through spindle style such as MM part numbers MMTR-1 or MMTR-3. The tapered stud type of kit will not have enough range of adjustment to correctly adjust bumpsteer with the geometry of the MM K-member.

96. Place the floor jack under the control arm, and support it at a comfortable working height. Install the spindle onto the balljoint. Thread the nut on a few turns.

97. We recommend installing MM caster/camber plates now if the car is not yet so equipped.

98. Install a front coil-over conversion kit now if the car is not yet so equipped.

99. Install the coil-over strut assembly into place in the caster/camber plate. Adjust the spacers between the upper spring perch and the caster/camber plate as per the MM Front Coil-over Kit instructions to allow for maximum bump travel.

100.Raise the floor jack to align the spindle to the strut. Install the strut bolts from the rearward side.

101.Attach the adjustable outer tie-rod end to the spindle. As a starting point, place a 2” stack-up of spacers between the spindle and the tie-rod end. Torque the tie rod end bolt through the spindle to the specification of your bump steer correction kit.

102.Torque the ball joint nuts to 129 ft-lbs.

103.Torque the spindle to strut bolts to 148 ft-lbs. Torque the strut top nut to the specification of your strut manufacturer.

104.Install the brake rotor. Install the brake caliper. Torque the caliper bolts to the factory specs for your caliper.

105.Repeat Steps 96 through 104 on the opposite side of the car.

Clearance

106.Place the floor jack under the control arm. Adjust the lower spring perch to its lowest possible position. Cycle the suspension through full bump and droop with the jack while turning the front wheels from lock to lock. Check for interference between any suspension components.

107.Reinstall the front wheels. Tighten the lug nuts.

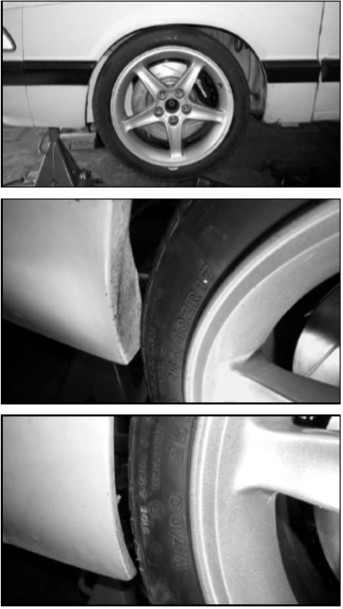

108.Depending upon the following parameters, there may be varying degrees of interference between the tire and the fender.

• Wheel size.

• Wheel offset .

• Tire size—be aware that the same nominal size tire from different manufacturers can have different actual sizes.

109.Again, place the floor jack under the control arm. Raise the control arm until the spindle is at your previous ride height. Use the dimension D1 you recorded in Step 3 to set the relationship between the spindle and the fender. Check for interference between the tire and the fender. Cycle the suspension through full bump and droop with the jack while turning the front wheels from lock to lock. Again check for interference between the tire and the fender. The inner fender lip may need to be rolled under for clearance. Also check for clearance between the tire and the front fender extensions. Be aware that the tire clearance may change after the front alignment is done.

110.In general, 1993 and earlier cars may have minor interference between the tire and the front fender extension while steering. This interference is minimal with the zero-offset control arms, and can be easily eliminated by trimming the fender extension.

111. With the forward-offset control arms, more extensive trimming of the fender extension is required, along with minor reworking or trimming of the fender’s sheet metal. A spreader bar may also be required to push the front portion of the fender further outwards from the chassis.

112. In general, 1994 and newer cars do not require any modifications when using the zero-offset control arms. Using the forward-offset control arms may require minor trimming of the plastic front bumper cover and front spoiler. This trimming is inside of the wheel well area, and is therefore very unobtrusive.

113. Raise the lower spring perch upwards until the spring is touching both the lower and the upper spring perches. Adjusting the spring perch so the spring is just starting to compress is a good starting point for adjusting ride height. Final ride height will be set after the car is back on the ground.

114. Remove the jack stands and set the car on the ground. Torque all your lug nuts to factory specifications. Roll the car back and forth to settle the suspension. Adjust the front ride height back to its original setting using the dimension D2 you recorded in Step 3. With the coil-overs you may also change the ride height to your liking.

115. With the ride height set check the position of the front control arms. If you have chosen the correct set of front control arm mounting holes the control arms will be close to being parallel to the ground. If not, you may want to either adjust the ride height or change to the other set of control arm mounting holes.

116. Do an approximate alignment of camber, caster and toe by eye. If camber or caster is changed significantly you may need to check tire clearance again by repeating the steps above.

117. Tighten the tie-rod end jam nuts. Check both the nut between the rod-end and the tie rod end sleeve, as well as the nut between the rack and tie rod end sleeve.

118. Reinstall the swaybar end links. It is likely that with the revised control arm geometry, you will need shorter end links. Rotate the sway bar until the forged end link hole is horizontal. Measure the distance between the sway bar end link hole and the sway bar end link hole in the front control arm. This is the ideal end link length. Use end links that are as close as possible to this dimension (19-408 to 19-417). Be careful not to over tighten and crush the endlink bushings.

119. Reconnect the battery ground cable.

Final Alignment

The car’s behavior before correcting the alignment and bump steer will be very unstable. Driving the car before the alignment and bumpsteer is corrected is not recommended.

Remember that the ride height must be set before doing the final alignment. Any time that the ride height is changed the camber and toe settings must be readjusted.

Alignment recommendations when using the MM K-member: For street driven cars, set caster at 6 degrees positive; camber at negative 0.75°; toe-in set to a total of 0.25°. Race car alignments are very dependent on tires, track, and driving style and should be adjusted according to tire wear, tire temperatures, and preferred balance of the car. Generally speaking, a more aggressive alignment than the street setting is desirable.

Bumpsteer

The camber, caster and toe must be set before correcting bumpsteer. Adjust the car’s bumpsteer according to the copyrighted instructions you received with your MM Adjustable Tie-Rod End Kit.

Test drive and enjoy! Re-torque all bolts and nuts after 1000 miles.