How to Install SR Performance Caster Camber Plates on your 1994-2004 Mustang

Installation Time

4 hours

Tools Required

- Jack and Jack Stands

- Air Powered Impact Wrench (recommended but not necessary)

- Other Tools

Shop Parts in this Guide

Note: You must have your car aligned after installation of the camber plates. If installing plates before driving to a shop for alignment, measure strut position before beginning and get strut as close to starting position as possible when installation is complete.

Take Note of Driver/Passenger Side Orientation Before Beginning Installation

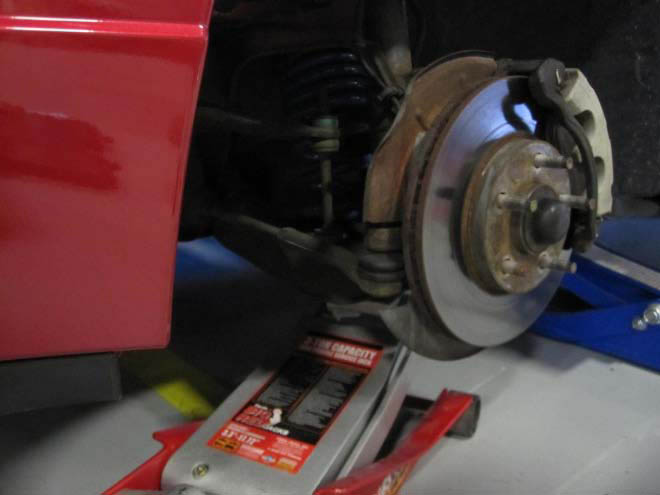

Step 1:

Support the front of the vehicle with jack stands

under the front frame rails. Place a floor jack

under driver’s side control arm and raise slightly

to take the weight off of the strut.

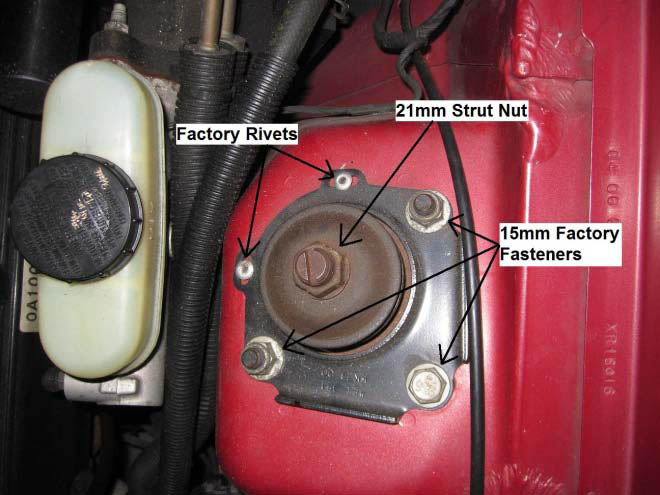

Step 2:

Use a drill or chisel to remove rivets (if still in

place), remove upper 21mm strut nut, and

remove 15mm factory plate fasteners. Note:

Removing the upper 21mm strut nut is easiest

with an air powered impact wrench.

Step 3:

With the factory plate loose, remove the upper

strut washer, rubber strut bushing, and upper

factory plate as shown.

Step 4:

Slowly lower the floor jack supporting the lower

control arm, letting the strut fall as far as

possible down in the strut tower. Reach in the

fender well and compress the strut, moving it

from the shock tower into the inner fender well.

Once in the fender well, remove the factory

lower plate.

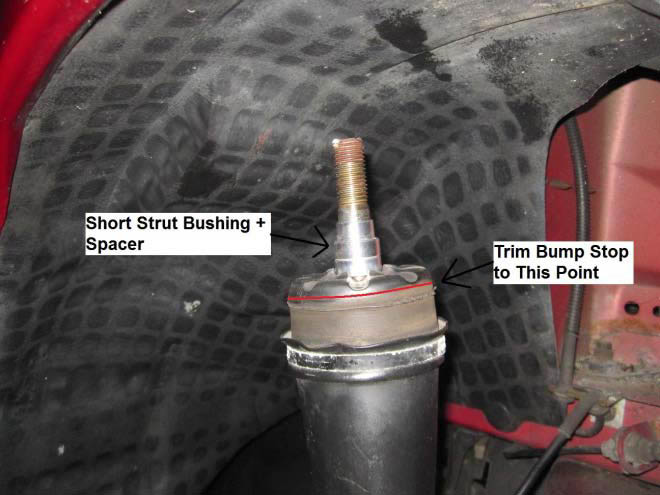

Step 5:

There are four different options for strut

spacing with your camber plates. Most cars will

use Option 2 (Cars lowered .5” - .75”) or Option

3 (Cars lowered 1” – 2”). Once the correct

spacing is determined, install the spacers as

shown below:

Note: These spacing option are simply

guidelines, cars may vary for a number of

reasons. If you experience bottoming problems

once the plates are installed, raise the strut to a

higher mounting position.

Option 1: This lowers the strut mounting point

from a stock setting. This setting is used when

shorter than factory height struts are used with

factory height springs.

Option 2: This raises the strut mounting point

from a stock setting. Use with cars at stock

height to cars slightly lowered (.5” - .75”).

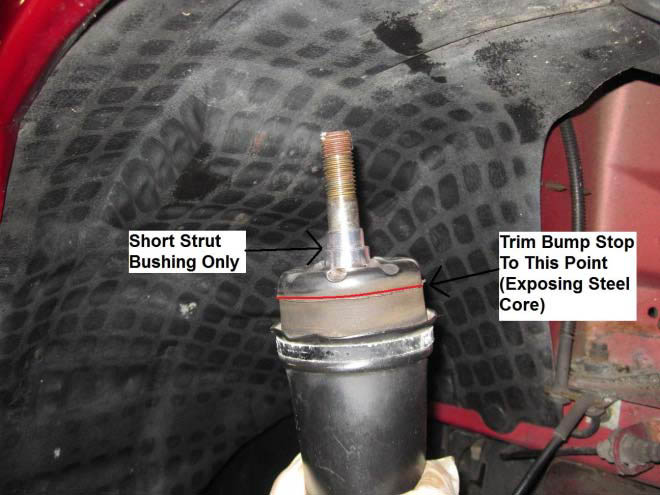

Note: In order to run the Option 3 or 4 setting,

you must trim the top of the rubber from the

bump stop to the indicated red line in the

photos below. This will prevent the rubber from

interfering with the underside of the strut

tower. You can use a hacksaw, Sawzall, etc to

cut the excess rubber

Option 3: This raises the strut mounting point

from a stock setting as well. Use with cars

lowered 1” – 2”.

Option 4: This setting should only be used

when experiencing strut bottoming problems

due to lowering springs with too soft of a spring

rate. It is necessary to remove all of the rubber

from the bump stop at this setting, and may

require grinding some of the steel down as well.

Step 6:

Install the drivers side stud plate in the strut

tower from inside the fender well. Install the

driver’s side top plate over the studs and use

the included washers & 15mm locking nuts to

secure the stud plate to the upper plate as

shown. Do not tighten the nuts yet, just install

them finger tight for the time being.

Step 7:

Compress the strut and move it back inside the

strut tower and through the camber plate,

making sure the small end of the strut bushing

mates properly with the bearing in the center of

the plate. It may be necessary to jack up

slightly on the control arm and gently persuade

the strut into place.

Step 8:

Install the remaining strut bushing over the

threaded end of the strut with the small end

facing down as shown. Make sure the small

end of the bushing slides flush into the bearing

housing. Re-install the large strut nut and

tighten to manufacturers specifications (Factory

Strut Spec is 65-85 ft/lb).

Step 9:

If you are driving the vehicle to have an

alignment performed, adjust the strut to

approximately the same position as before the

install and tighten the 3 stud plate bolts and 3

Allen head bolts to 25-30 ft/lb.

Step 10:

Remove the floor jack from under the control

arm and repeat Steps 2-9 for the opposite side

plate to complete the installation.

Note: Before closing hood, check clearance

between the outer stud plate bolts and the

hood. If necessary, file the bolt slightly to allow

for proper clearance (make sure nut is installed

on stud before filing, drawing it off of the stud

will repair any damaged threads).

Alignment Notes:

An alignment must be performed after

installation of these caster camber plates or you

will experience poor handling and uneven tire

wear. It is highly recommended that the vehicle

be brought to a credible repair shop with the

proper equipment to align the vehicle within

factory (or customized) specifications.

Camber:

To adjust camber, loosen the three 15mm

locking nuts securing the upper plate to the

stud plate and move the upper plate towards

the fender to increase camber (positive

camber), or towards the engine to decrease

camber (negative camber). As a general rule,

the more negative camber, the better cornering

grip a vehicle will have. However, this comes at

the expense of rapidly increased tire wear in

the inside edge of the tire. Conversely, the

more positive camber, the less cornering grip

the vehicle will have. Too much positive

camber can rapidly wear the outside edge of

the tire.

Caster:

To adjust caster, loosen the three Allen head

bolts securing the bearing housing to the upper

plate and move the bearing housing towards

the firewall to increase caster (positive caster),

or towards the front bumper to decrease caster

(negative caster). Most cars will benefit from

an increased amount of positive caster,

however too much positive caster can result in

bumpsteer issues if not addressed properly.