How to Install US Speedo Stainless Steel Aqua Series 6 Gauge Insert on your Mustang

Shop Parts in this Guide

05-08 Mustang

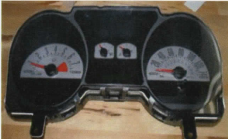

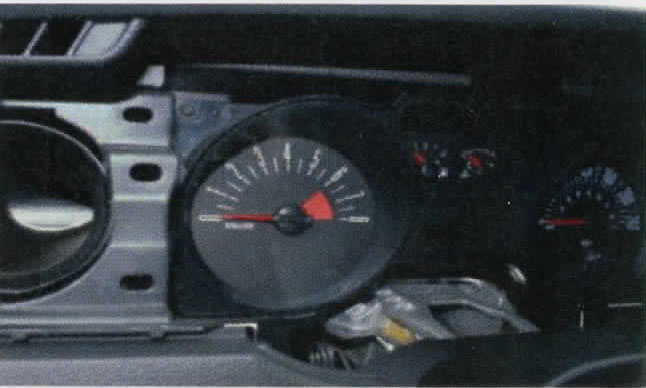

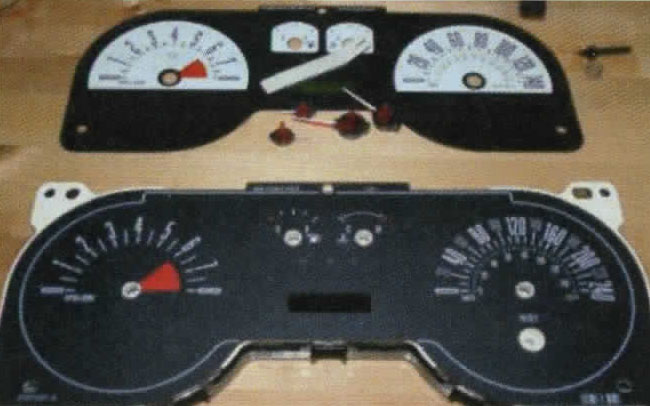

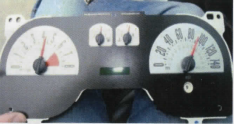

1. Mark on the diagram each needle

location. Key OFF

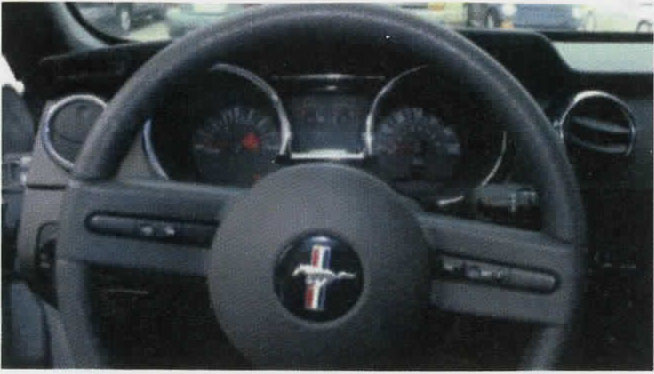

3. Pull on the right side of the vent.

4. Slide the trim piece to the left to remove.

It only has clips to secure it.

5. Remove the four 7mm screws holding

the cluster in place.

6. Push down on the center and slide the

handle over to remove.

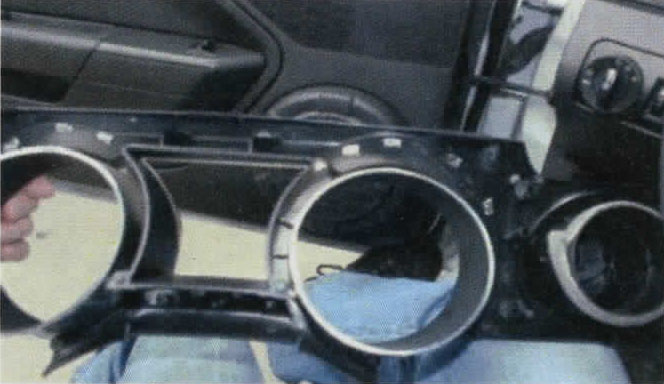

7. Take the cluster to a clean work area.

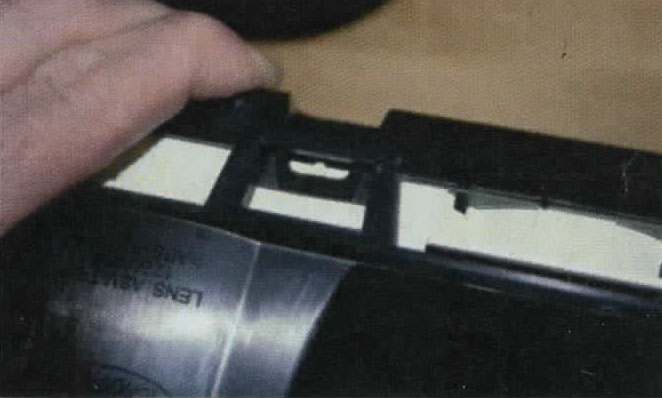

8. Remove the top lens. I is only held on with

clips.

9. Only remove the top lens.

10. Turn the needles down past the low

marks.

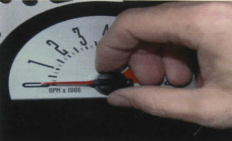

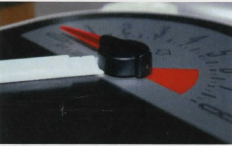

Step 11. Use the needle tool to remove the needles. Twist and lift if needed.

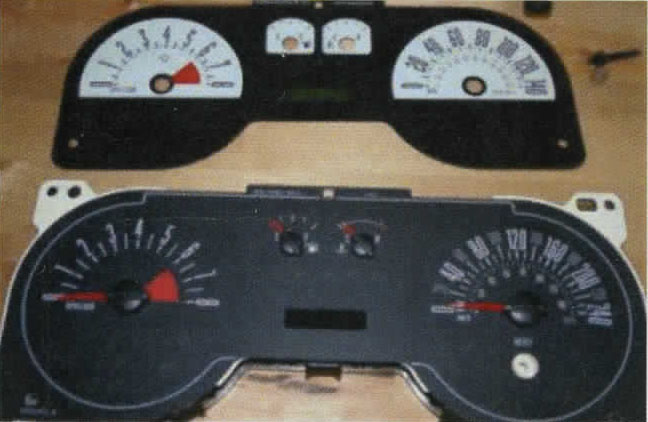

12. Remove the black gauge face. It has glue

on the back of the gauge face.

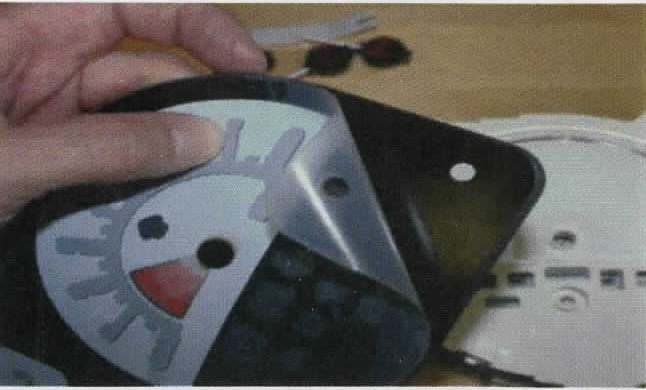

13. On the back of the US Speedo gauge is a

clear liner. Remove.

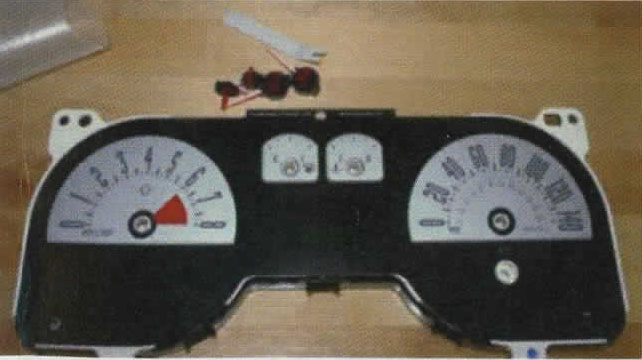

14. Place the gauge face in place. SS and Aqua kit will come with gloves.

15. Leave the key off and plug the cluster in.

16. You will hear the motors reset. Place the

needles into position.

17. Do not push all the way down yet.

18. Unplug the cluster.

19. With the cluster in your lap, move the

needles straight up.

20. Plug the cluster back in. Each needle should go back to the low marks.

21. If a needle is wrong, unplug the cluster

and remove the needle.

22. Return to step 15 if a needle is wrong.

If not, continue.

23. Push the hub down until it makes contact with the handle of the needle tool.

24. Some models have the reset button, set in

place.

25. Snap the lens in place and install the

cluster.