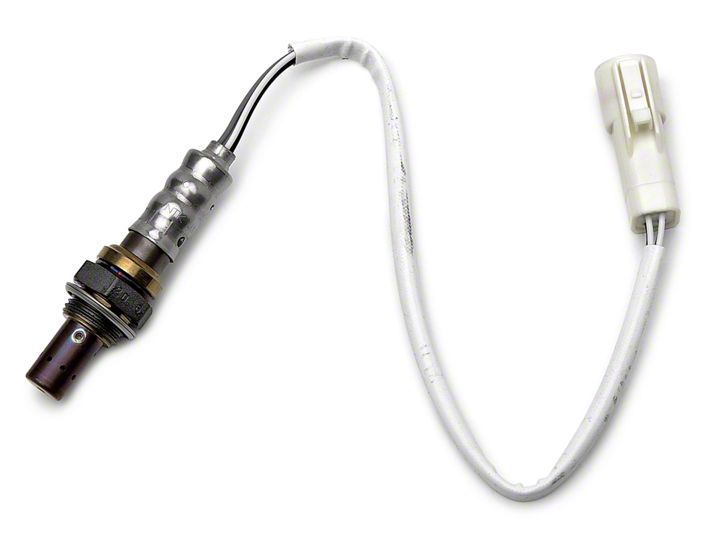

How to install an NTK Performance Oxygen Sensor on your Mustang

Shop Parts in this Guide

Installation

Installation & Wiring Instructions for Universal Oxygen Sensors

1. DISCONNECT OLD OXYGEN SENSOR CONNECTOR FROM VEHICLE HARNESS USING EXTRA CARE NOT TO DAMAGE CONNECTOR, AS IT MUST BE REUSED.

2. REMOVE OLD SENSOR FROM VEHICLE USING AN O2 SENSOR SOCKET OR 22MM WRENCH. PLACE THE OLD AND NEW OXYGEN SENSORS SIDE BY SIDE ON A FLAT SURFACE, PREPARING TO MAKE AN ACCURATE CUT OF THE LEAD WIRES. CUT THE LEAD WIRE(S) OF THE OLD SENSOR TO A LENGTH THAT WHEN THE PLUG END IS SPLICED TO THE NEW UNIVERSAL SENSOR, THE OVERALL LENGTH WILL BE THE SAME OR SLIGHTLY LONGER THAN THE OLD SENSOR.

IMPORTANT!! (BEFORE MAKING THE CUT, ADD 2” TO 3” OF ADDITIONAL LENGTH TO THE PLUG END TO ALLOW FOR THE EXTRA WIRE NEEDED WHEN MAKINGTHE STAGGERED SPLICE) - SEE FIG. 1 (PG 3)

3. STAGGER-CUT WIRE LEAD(S) STRIPPING OFF APPROX. 1/ 4” OF INSULATION FROM THE END OF EACH WIRE.

>>> FOR STEPS #4 AND #5 PLEASE REFER TO THE ATTACHED WIRE PLACEMENT & COLOUR CODING DIAGRAMS (PAGES 4-12) TO DETERMINE PROPER WIRE MATCHING OF UNIVERSAL SENSOR LEAD(S) TO CONNECTOR LEAD(S) FOR EACH SPECIFIC APPLICATION (HEATER WIRES ARE NOT POLARITY DEPENDANT

4. A) ON UNIVERSAL SENSORS WHERE HEAT-SHRINK TUBE(S) ARE ALREADY INSTALLED: INSERT JUST STRIPED PORTION OF WIRE(S) INTO CRIMP TERMINALS OF NEW SENSOR AND CRIMP TERMINALS

5. B) ON UNIVERSAL SENSORS WHERE HEAT-SHRINK TUBE(S) ARE NOT INSTALLED: INSERT JUST STRIPED PORTION OF WIRE(S) INTO CRIMP TYPE "BUTT" CONNECTORS (APPROX. 1/4”) AND CRIMP.

6. AFTER ALL CONNECTIONS HAVE BEEN MADE, SLIP THE HEAT SHRINK TUBE OVER THE CRIMPED CONNECTIONS AND HEAT THE TUBE WITH AN APPROPRIATE HEAT SOURCE UNTIL THE CONNECTION IS COMPLETELY SEALED, TAKING CARE NOT TO OVER-HEAT OR BURN TUBING (SEE FIG. 3, PG 3).

7. REMOVE PROTECTOR CAP JUST PRIOR TO INSTALLATION

- A) FLANGED APPLICATIONS- (WHERE FLANGE IS NOTALREADY INSTALLED ON SENSOR) INSTALL FLANGE TO EXHAUST MANIFOLD FIRST, THEN MOUNT SENSOR IN FLANGE (A COPPER GASKET IS BONDED TO THE FLANGE & NO ADDITIONAL GASKET IS REQUIRED)

- FLANGED APPLICATIONS- (WHERE FLANGE IS ALREADY INSTALLED ON SENSOR) (IT IS IMPORTANT TO USE THE SUPPLIED GASKET BEFORE INSTALLING SENSOR)

8. IF NOT ALREADY COATED, APPLY (ENCLOSED) ANTI-SEIZE TO OXYGEN SENSOR THREADS

9. INSTALL SENSOR BODY ENSURING LEAD WIRE IS NOT TWISTED OR BENT

10. INSTALL ALL SENSORS WITH NEW GASKET SUPPLIED & TORQUE TO PROPER SPECS AS BELOW:

M18 SENSORS - INSTALL FINGER TIGHT THEN 1/2 -3/4 TURN WITH WRENCH / O2 SENSOR SOCKET 35-45NM

M12 SENSORS - INSTALL FINGER TIGHT THEN 3/4 - 1 TURN WITH WRENCH / O2 SENSOR SOCKET 18-23NM

11. CONNECT AND ROUTE LEAD WIRE AS ORIGINALLY INSTALLED

Warning: Anti-seize compound may cause irritation to the skin or eyes. In case of contact, wash affected area with soap and water. In case of eye contact, flush with water for 15 minutes. If irritation persists, consult a physician. If swallowed, do not induce vomiting.

Keep out of reach of children.

O2 SENSOR WIRE PLACEMENT INSTRUCTIONS

THE FOLLOWING ILLUSTRATIONS REPRESENT THE MOST COMMON CONNECTOR TYPES FOUND ON THE MAJORITY OF DOMESTIC AND IMPORT APPLICATIONS IN USE. NOTE THAT THIS IS NOT AN ALL INCLUSIVE LIST AND APPLIES ONLY TO THE NEW O2 SENSOR. WIRE COLORS ARE INCLUDED FOR CONVENIENCE AND MAY VARY ACCORDING TO DIFFERENT MANUFACTURERS. HOWEVER, PROPER WIRE PLACEMENT AS SHOWN IN THE ILLUSTRATION SHOULD BE FOLLOWED. MAKE SURE THE POSITION OF THE OLD CONNECTOR MATCHES THE DIAGRAM AND CONNECT NEW SENSOR WIRES AS INDICATED (HEATER WIRES ARE NOT POLARITY DEPENDANT.