How to Install AWE Touring Edition Axle-Back Exhaust on your Mustang

Installation Time

2 hours

Tools Required

- 7/16” or 11mm Socket

- 13mm Socket

- 15mm Socket

Shop Parts in this Guide

- AWE Touring Edition Axle-Back Exhaust with Chrome Silver Tips (15-17 Mustang GT)

- AWE Touring Edition Axle-Back Exhaust with Diamond Black Tips (15-17 Mustang GT)

- AWE Track Edition Axle-Back Exhaust with Chrome Silver Tips (15-17 Mustang GT)

- AWE Touring Edition Cat-Back Exhaust with Chrome Silver Tips (15-17 Mustang GT Fastback)

- AWE Touring Edition Cat-Back Exhaust with Diamond Black Tips (15-17 Mustang GT Fastback)

- AWE Track Edition Cat-Back Exhaust with Chrome Silver Tips (15-17 Mustang GT Fastback)

- AWE Track Edition Cat-Back Exhaust with Diamond Black Tips (15-17 Mustang GT Fastback)

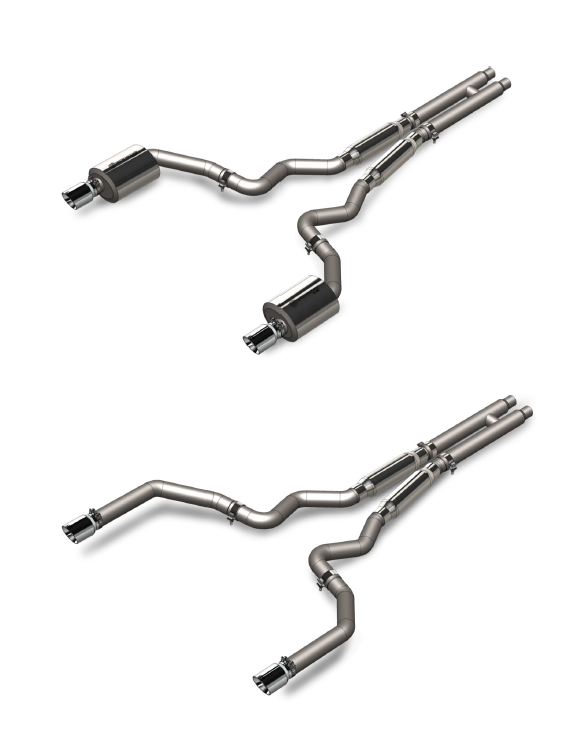

TRACK & TOURING EDITION

1 H-Pipe section (part XE)

1 Driver axle section (part XG)

1 Passenger axle section (part XJ)

2 102mm slash cut tips (optional finish)

Touring Edition Only:

1 Driver rear section (part XK)

1 Passenger rear section (part XL)

Track Edition Only:

1 Driver rear section (part XM)

1 Passenger rear section (part XN)

Hardware Kit:

4 3.0” (76.2mm) Accu-Seal clamps

2 3.0” (76.2mm) T-Bolt clamp

STEP 1:

Installation of the AWE performance exhaust system is the reverse of the OEM exhaust removal.

Always refer to the manufacturer service manual for precise torque specifications on all OEM fasteners.

Before removing the factory exhaust, soak the fasteners that hold the exhaust in place with a penetrating oil.

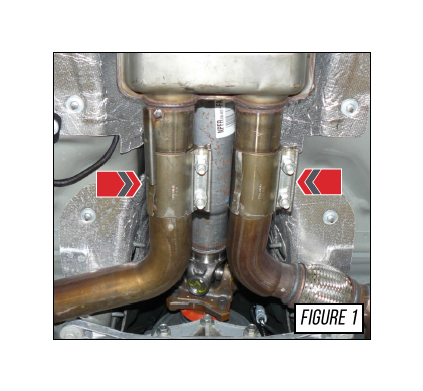

Loosen the two (2) factory sleeve clamps located just forward from the mid muffler with a 15mm socket, as shown by the arrows in Figure 1.

Note the sleeve orientation so they can be reinstalled the same way they were removed.

STEP 2:

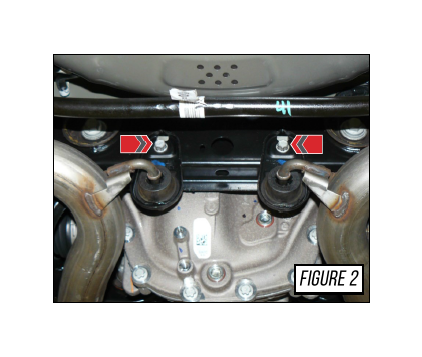

Remove the 13mm bolts that secure the factory exhaust hangers located behind the rear differential, shown by the arrows in Figure 2.

Ensure the exhaust hanger bracket drops into the catch slots on the cross-member.

STEP 3:

Remove the 13mm bolts securing the hanger brackets located at the rear of the vehicle, shown by the arrows in Figure 3.

Ensure the exhaust hanger brackets drop into the catch slots on the frame rail.

With all the bolts from the hanger brackets removed, the factory exhaust can be removed from the car.

STEP 4:

Transfer the hanger bushing and bracket assemblies from the OEM exhaust to the correlating AWE components.

The passenger side axle tube (part XJ) is shown with the factory hanger pre-installed by the arrow in Figure 4.

Be sure to maintain the original side and orientation, as the brackets are handed.

STEP 5:

Install the AWE H-Pipe section (part XE), reusing the original sleeve clamps that were loosened in Step 1. Match the original orientation.

Pre-install two 3.0” Accu-Seal clamps onto the outlet section of the H-Pipe.

Install the axle tubes (parts XG & XJ) onto the H-pipe first then hang the pipe by the installed hanger bracket, as shown by the arrow in Figure 5. (part XJ shown)

Do not fully tighten any of the clamps or hanger brackets until the system is fully installed and adjusted.

STEP 6:

Pre-install two 3.0” Accu-Seal clamps onto the outlet portion of each axle section.

Install the driver rear section (part XK) and passenger rear section (part XL) along with the exhaust tips.

Tighten the exhaust hanger brackets into location with the 13mm socket.

Install the exhaust tips with the included 3.0” T-Bolt clamp.

Center the exhaust tip within the valance, as shown in Figure 6. The AWE logo should be visible at the top edge; make adjustments as necessary.

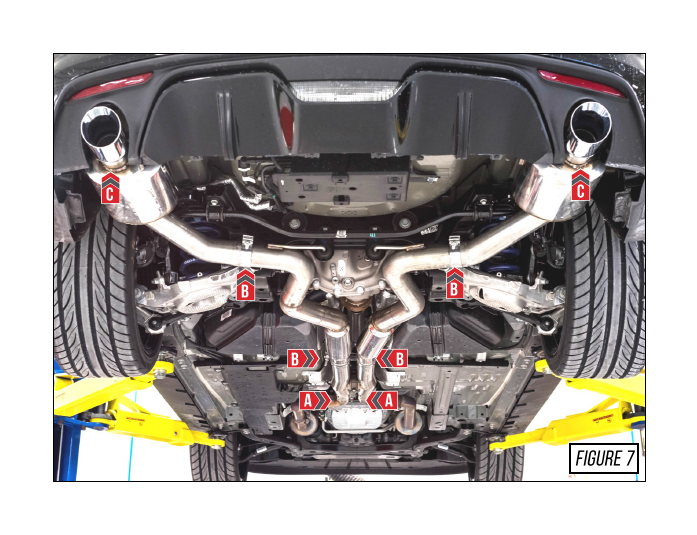

STEP 7:

Ensure the H-pipe section is level with the chassis. Tighten the factory sleeve clamps to the manufacturer’s recommended torque specifications, located by Arrow A in Figure 7.

Tighten the Accu-Seal clamps to a minimum torque of 40 ft/lbs or until secure with a 15mm socket, as shown by Arrow B in Figure 7,

Check the tip alignment and secure the T-bolt clamp into location, as shown by Arrows C in Figure 7, with 7/16” or 11mm Socket. Tighten until the tip doesn’t move, then turn the bolt one (1) full turn.