A bad clutch will cause you to lose races and possibly cause damage to the rest of your Mustang. This guide will help you to pick the right clutch for your Mustang!

Contents

- Clutch Overview

- How To Operate a Mustang's Clutch

- The Ford Mustang's Clutch System

- Your Mustang's Engine

- The Mustang's Flywheel

- Mustang Pressure Plates, Throw-out Bearings, & Clutch Forks

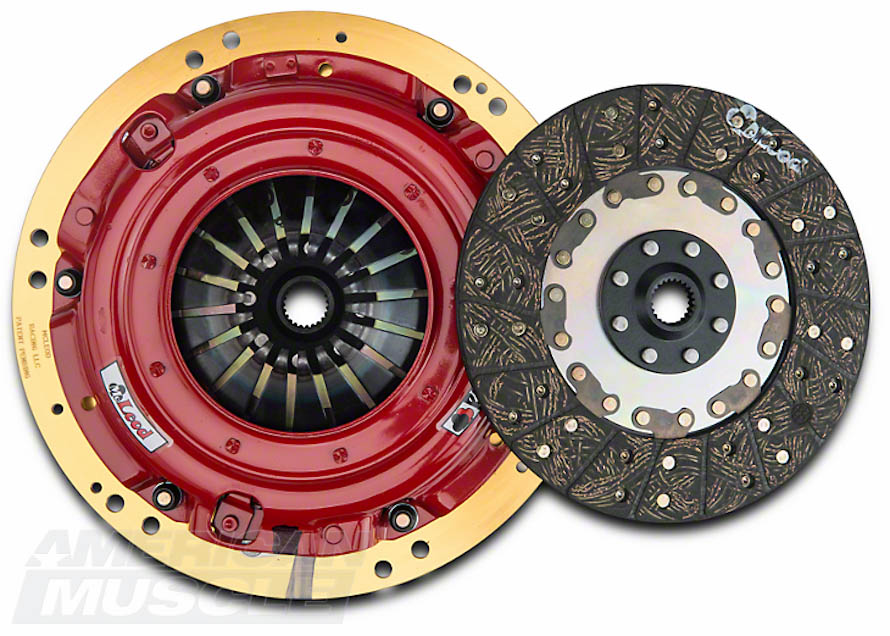

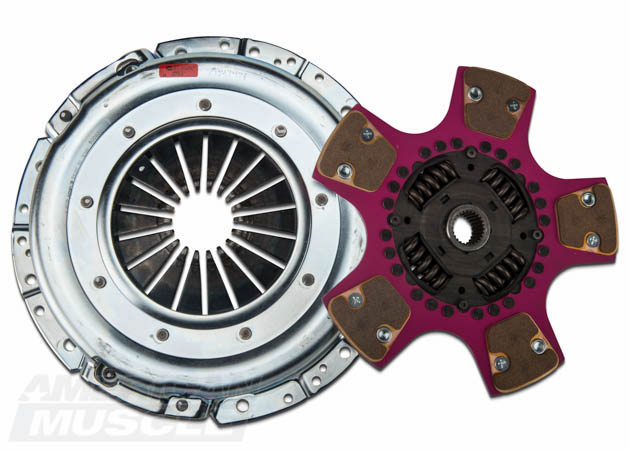

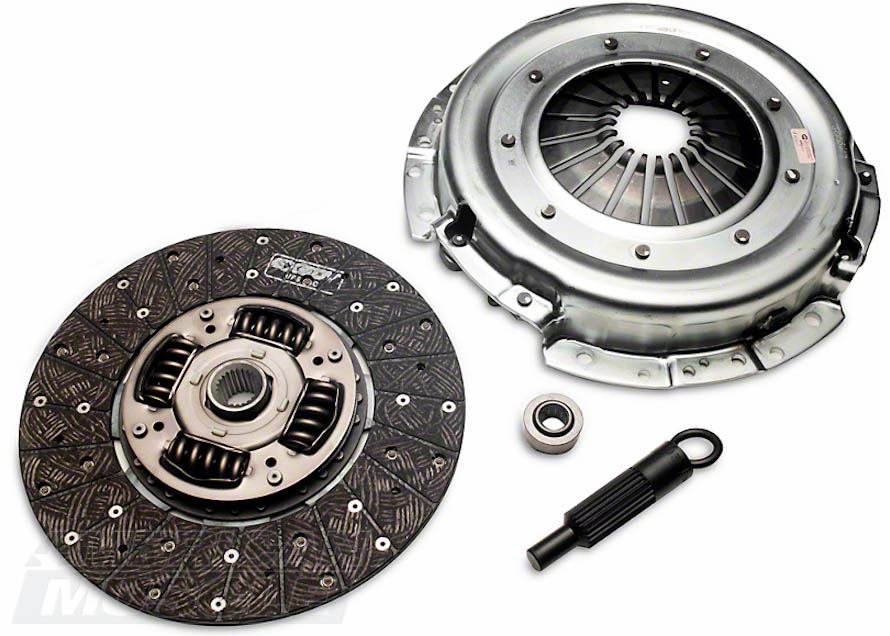

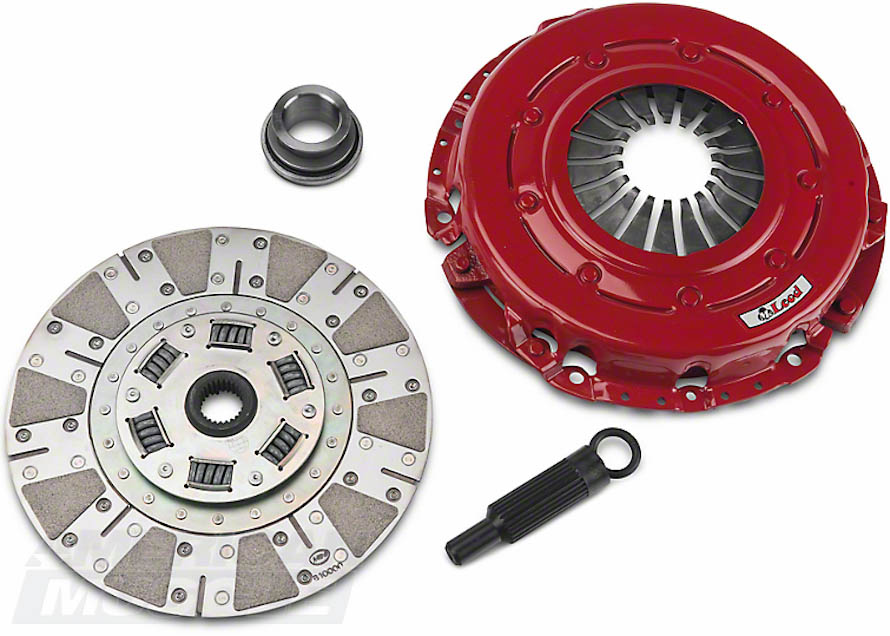

- Different Types of Mustang Clutch Discs

- What is a Twin Disc Clutch?

- Mustang Torsion Dampeners

- Different Clutch Materials

- Overview of Clutch Materials and Their Differences

- Understanding Clutch Material And How To Purchase One

- What Is A Clutch Stage?

- What Stage Clutch Should I Buy?

- Clutch Stage Broken Down

- What is Over Clutch?

- What are Mustang Clutch Springs?

- Do I Need to Replace the Flywheel When Replacing a Clutch?

- What is the Break in Period for a Mustang's Clutch?

- Why Should I Buy an Adjustable Clutch Kit?

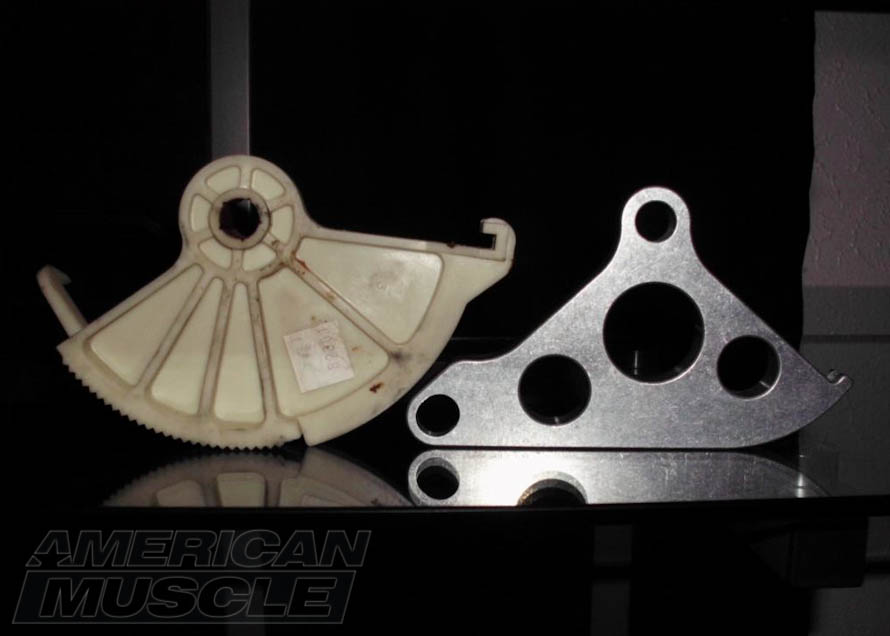

- Stock Mustang Flywheel Material

- Slave Cylinders - Why They're Important

- 2005+ Mustangs: How to Bleed the Slave Cylinder

- Pedal Stiffness & What Affects It

- Mustang Clutch Lines Explained

- Which Clutch is Best For My Mustang?

Shop Mustang Clutches

There are many different types of clutches and choosing the right one for your application can be daunting. Using the guide below you can narrow down what you're looking for and pick up the proper clutch for your Mustang.